Mems gas sensor chip, sensor and preparation method of sensor

A gas sensor, gas-sensitive technology, applied in thermometers, instruments, temperature control and other directions using electrical/magnetic components that are directly sensitive to heat, can solve the problems of high price, long response time, poor environmental stability, etc., to achieve the response time Short, less impact, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

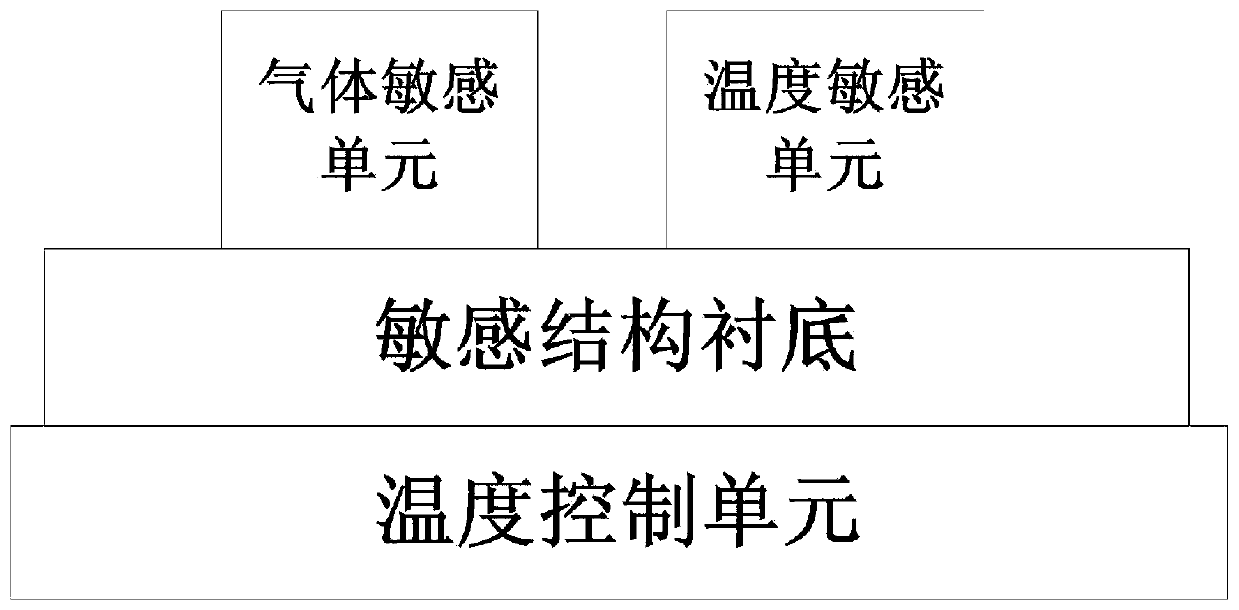

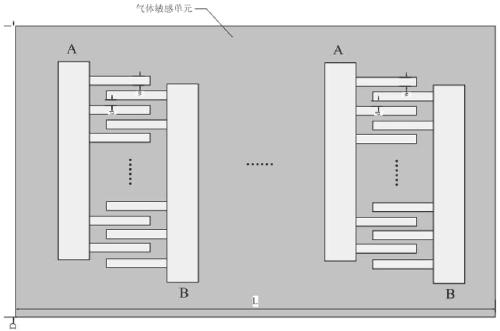

[0069] Such as figure 1 As shown, a specific embodiment of the present invention discloses a MEMS gas sensor chip, including a gas sensitive unit, a temperature sensitive unit, a sensitive structural substrate and a temperature control unit.

[0070] The gas sensitive unit and the temperature sensitive unit are in the same layer, they are respectively arranged above the sensitive structural substrate, and the bottom surfaces of both are in direct contact with the upper surface of the sensitive structural substrate.

[0071] The temperature control unit is arranged under the sensitive structure substrate and includes two electrical interfaces. The temperature control unit is used to control the temperature of the sensitive structure substrate surface.

[0072] During implementation, one electrical interface of the temperature control unit is grounded, and the other is connected to the control signal. When the actual temperature collected by the temperature sensitive unit is h...

Embodiment 2

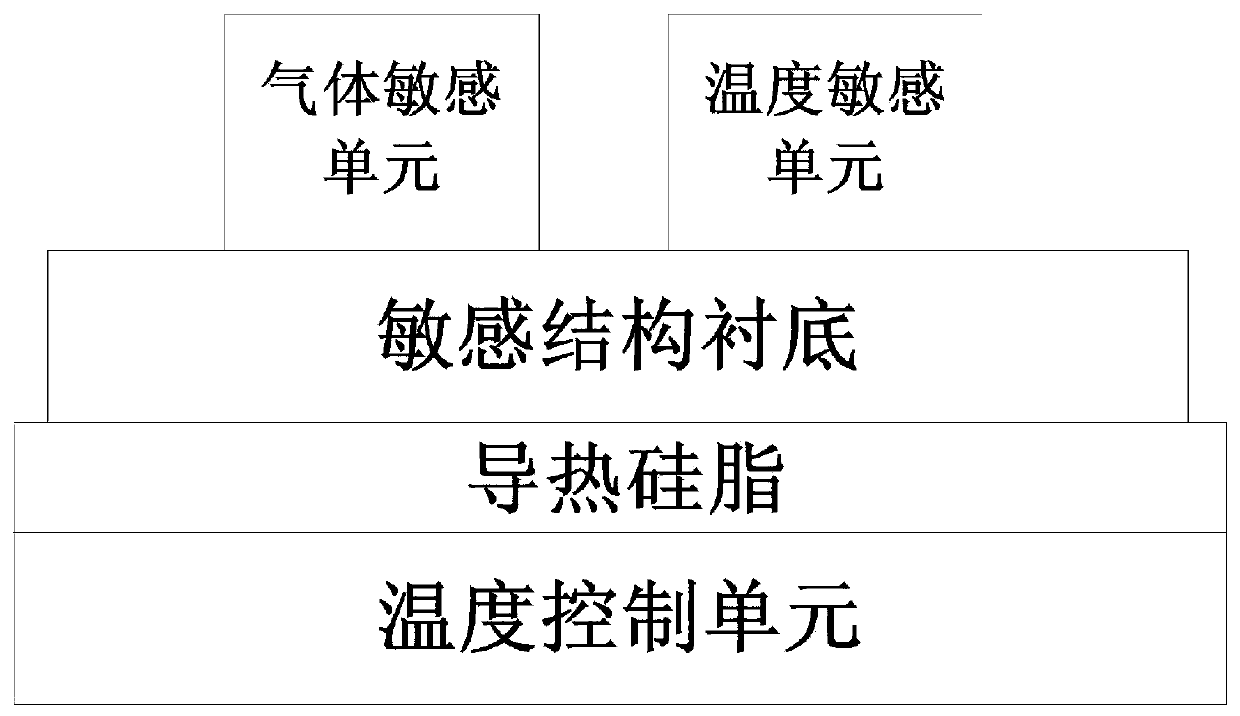

[0075] Such as figure 2 As shown, optimization is carried out on the basis of the foregoing embodiments, the MEMS gas sensor also includes colloidal silicone grease with better thermal conductivity, and the upper surface of the temperature control unit passes through the colloidal silicone grease with better thermal conductivity and the sensitive structural substrate. The bottom surface is connected, and the thickness of the colloidal silicone grease layer does not exceed 50 μm. Good thermal conductivity means that the thermal conductivity of thermal silicone grease reaches above 2.0W / (m*K), the working environment temperature ranges from -40°C to 200°C, and its thickness is generally 1-5mm, which can be controlled by the application process thickness. Existing heat-conducting silicone greases for cooling CPUs can generally meet the above requirements.

[0076] Preferably, there may be one or more gas sensitive units and temperature sensitive units above the sensitive struc...

Embodiment 3

[0091] Such as Image 6 As shown, this embodiment provides a MEMS gas sensor, including a MEMS gas sensor chip and a control circuit. The control circuit includes a microcontroller, an N-type MOSFET, a P-type MOSFET, and a power supply.

[0092] The input terminal of the microcontroller receives two input signals, one is the measured temperature output by the temperature sensitive unit, and the other is the preset temperature, which is set by the user according to the working requirements of the sensor. The output terminals of the microcontroller are respectively connected with the gates of the N-type MOSFET and the P-type MOSFET.

[0093] The source of the N-type MOSFET is connected to the source of the P-type MOSFET; the drain of the N-type MOSFET is connected to the positive power supply, and the drain of the P-type MOSFET is connected to the negative power supply.

[0094] One electrical interface of the temperature control unit is respectively connected to the source of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| interdigital gap | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com