A direct tensile tensile strength testing device and method for soft rock and soil

A tensile strength, testing device technology, applied in the direction of measuring device, strength characteristics, using stable tension/pressure to test the strength of materials, etc. It can reduce the size and quality of the device, the test process is simple and clear, and the cost of instrument manufacturing can be saved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The present invention is further illustrated by the following examples, but not limited to the following examples.

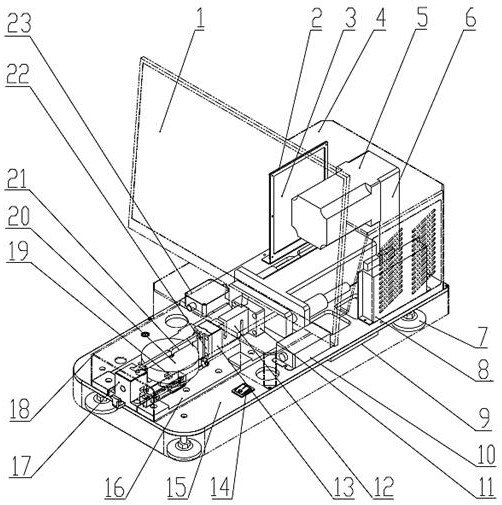

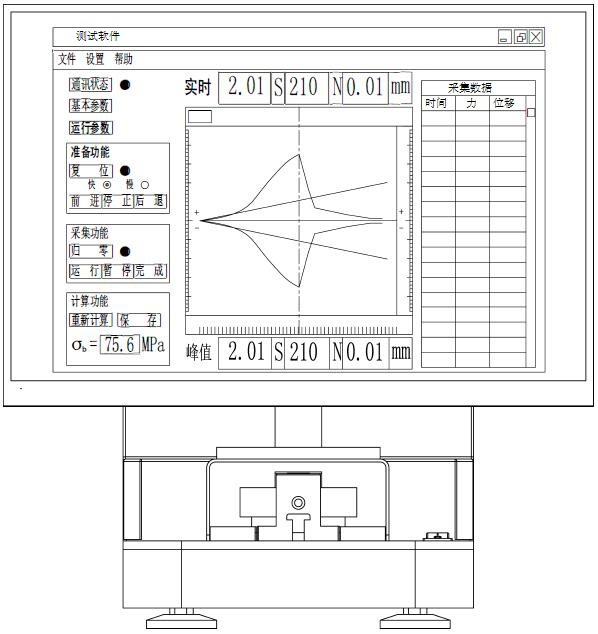

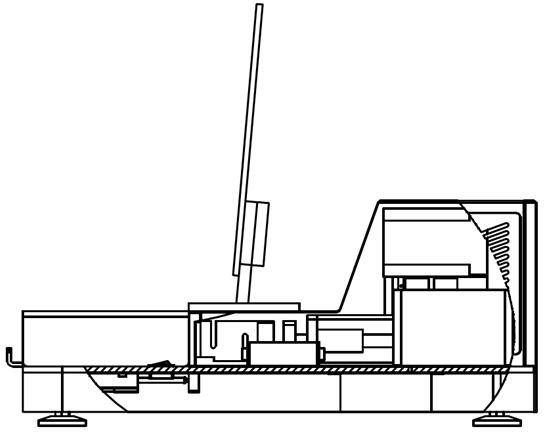

[0078] A direct tension tensile strength test device for soft rock and soil, the device includes a mechanical part and a control part; Board 13, sensor adapter board 1, pull rod device 21; the control part includes computer 1, stepping motor 5, stepping driver 8, control board 3, power supply module 9, tension signal converter 23, displacement signal converter 10, power supply Switch 14, tension sensor 12, displacement sensor 19; computer 1 is connected with the mechanical part of the device through the control board 8; through supporting software, computer 1 realizes the control of the mechanical part and the collection and processing of test data.

[0079] The fixed frame 17 is fixed on the middle part of the front end of the base plate 15; the central axis direction of the base plate 15 is provided with a guide groove, and the movable frame 22 is embed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com