Flexible ion sensor based on tungsten diselenide

An ion sensor, tungsten diselenide technology, applied in the field of MEMS, can solve the problems of inability to distinguish measured ions, device performance drift, poor selectivity of tungsten diselenide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the embodiments.

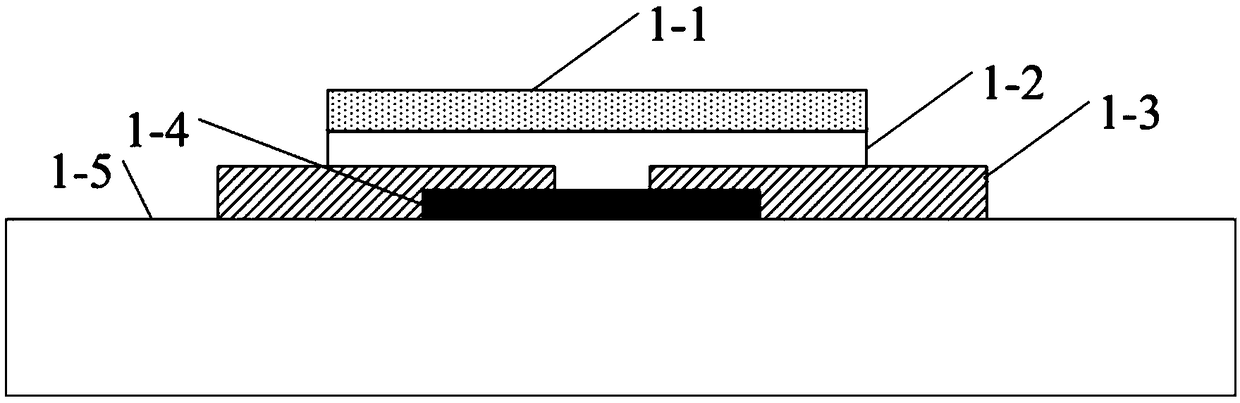

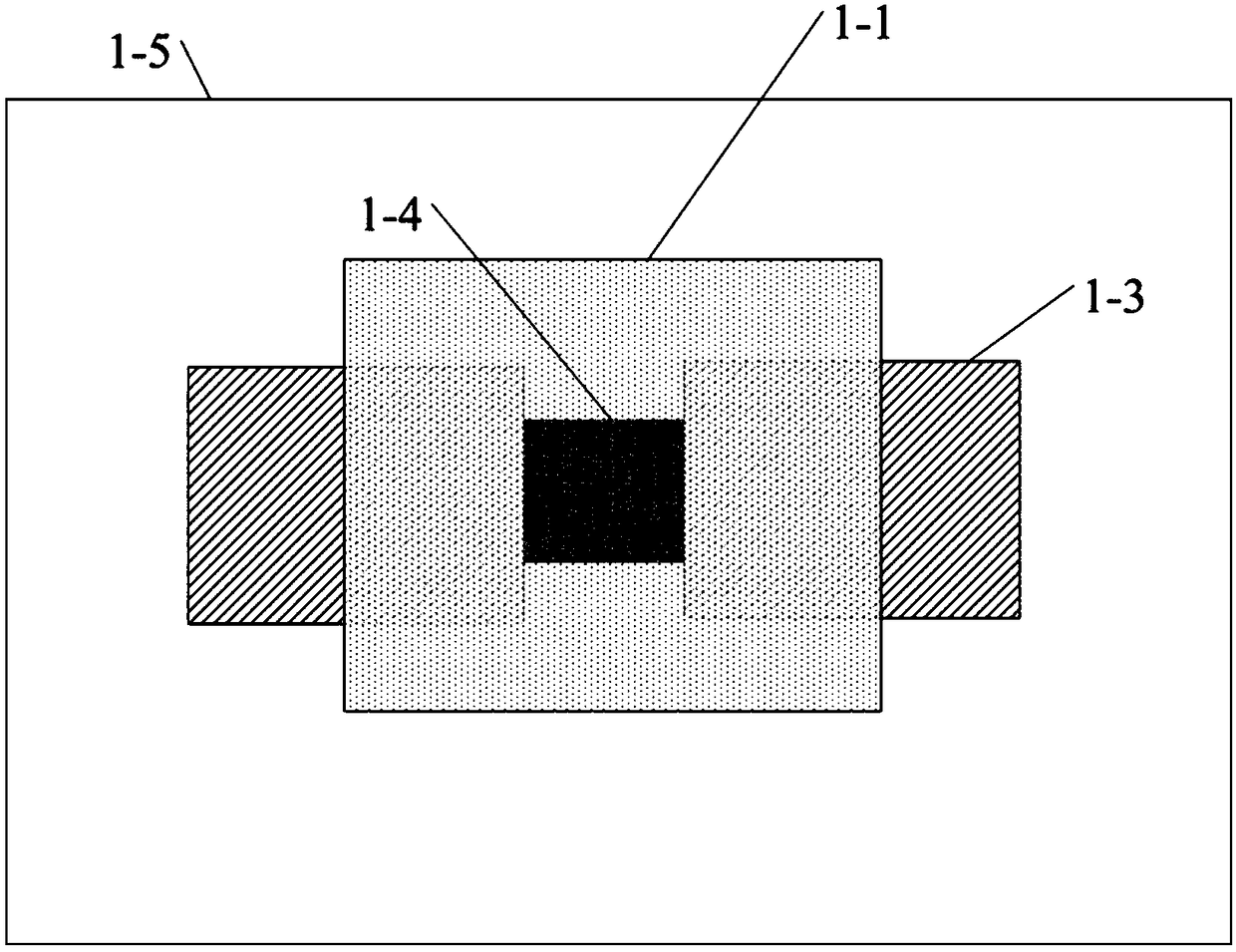

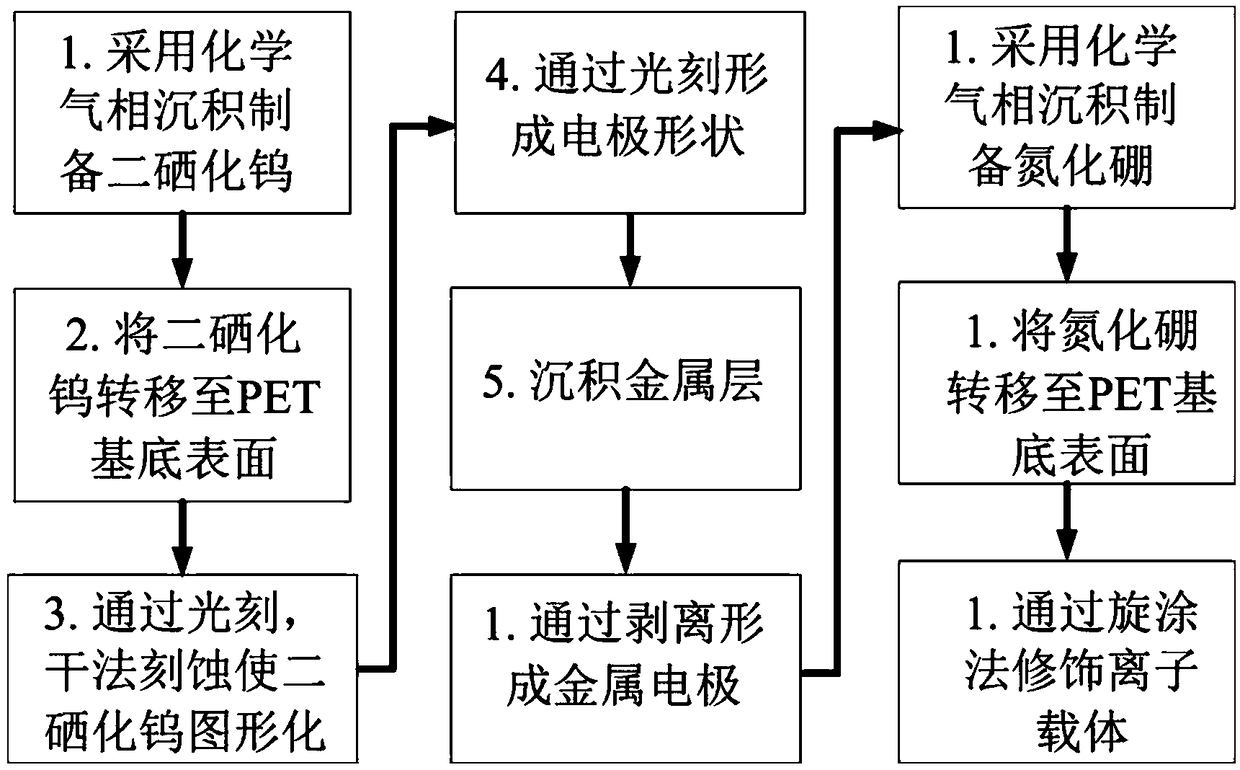

[0026] refer to figure 1 , figure 2 , a flexible ion sensor based on tungsten diselenide, characterized in that, from top to bottom, the sensor is ion carrier 1-1, boron nitride layer 1-2, metal electrode 1-3, tungsten diselenide Layer 1-4, flexible substrate 1-5, both ends of the tungsten diselenide layer 1-4 are connected to metal electrodes 1-3.

[0027] The ionophore 1-1 has a thickness of 20-200 microns.

[0028] The boron nitride layer 1-2 is a single layer or multiple layers, generally 1-10 layers, and when the thickness of the boron nitride material is reduced to 10 layers or less, it becomes a two-dimensional material, and its material properties are completely different from those of the block Bulk boron nitride material. The material of the metal electrodes 1-3 is selected from any one of Au, Ag, Cu, Al and Pt, and the thickness is 20-2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com