Purge and trap method for aroma components in tobacco and tobacco products

A fragrance component, purging and trapping technology, applied in the direction of material separation, material analysis, measuring devices, etc., can solve the problems of low steam distillation efficiency, large amount of organic solvent usage, long time-consuming purging process, etc., and achieve high sensitivity , No pollution in operation, easy and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

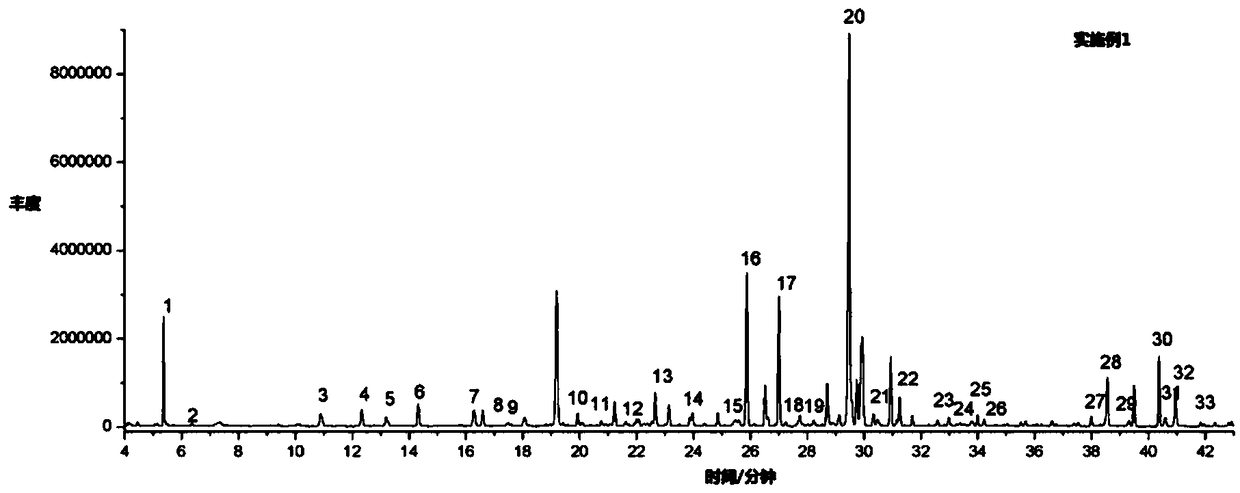

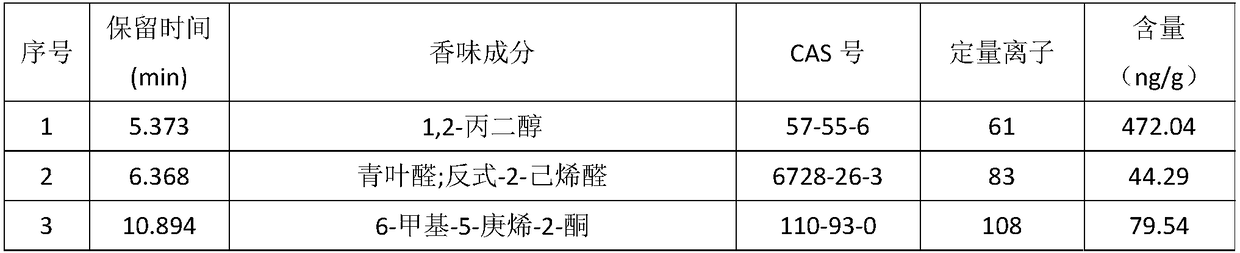

Embodiment 1

[0046] A purge and trap method for aroma components in tobacco and tobacco products, comprising the following steps:

[0047] (1) Tobacco and tobacco products are processed into shredded tobacco of 1mm×10mm;

[0048] (2) Take shredded tobacco and mix it with water at a weight-to-volume ratio of 1:18 to obtain an aqueous solution;

[0049] (3) Ultrasonic water bath extraction is performed on the aqueous solution, the ultrasonic power is 1400W, the ultrasonic temperature is 80°C, and the time is 60min, to obtain the extract;

[0050] (4) draw 20ml extract and place in the purging bottle, add the sodium chloride that is 25% by weight;

[0051] (5) The purge gas passes through the sample in the purge bottle, and the aroma components are volatilized from the water phase with the purge gas by bubbling. The purge temperature is 80°C, the flow rate of the purge gas is 20ml / min, and the purge time is 25min. ;

[0052] (6) Aroma components are trapped when they pass through the trap,...

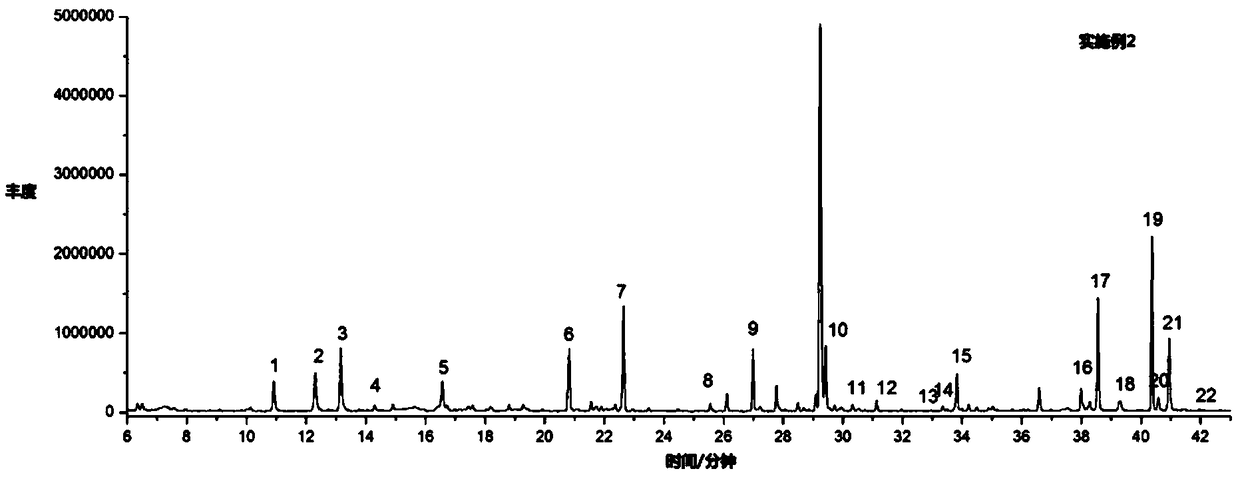

Embodiment 2

[0059] A purge-and-trap method for aroma components in tobacco and tobacco products, wherein the purging temperature in step (5) is 60°C. Others are with embodiment 1.

[0060] The name, quantified ion and content of the aroma components obtained in this embodiment are shown in Table 2, and the total ion current chromatogram of the aroma components is shown in figure 2 .

Embodiment 3

[0062] A purge-and-trap method for aroma components in tobacco and tobacco products, wherein the ultrasonic temperature in step (3) is 72°C. Others are with embodiment 1.

[0063] In this embodiment, a total of 19 quantifiable aroma components were detected, indicating that within a certain temperature range, when the ultrasonic temperature is low, the extraction efficiency is low.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com