A kind of complementary resistive memory and its preparation method

A resistive variable memory, complementary technology, applied in the direction of electrical components, etc., can solve the problems of unfavorable large-scale commercial application, increase device complexity and cost, etc., achieve simple composition and crystal structure, increase storage density, and operate at low voltage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below knot and accompanying drawing and specific embodiment, the present invention is further elaborated, but the present invention is not limited to following embodiment, described method is conventional method if no special instructions, and described raw material all can be from open commercial channel if no special instructions And get.

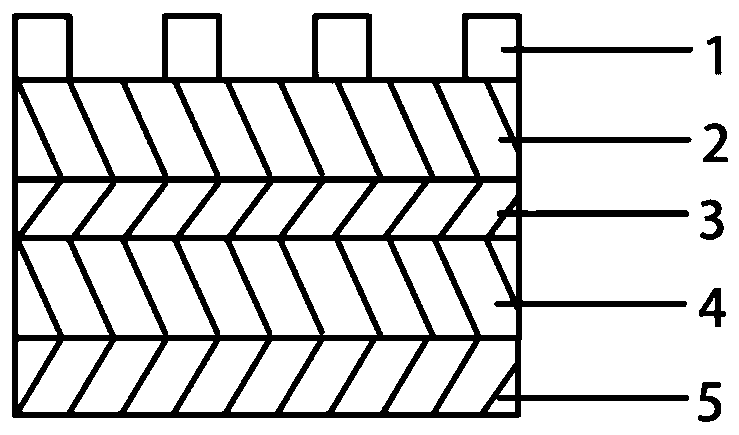

[0033] like figure 1 As shown, the complementary resistive variable memory of this embodiment includes an ITO electrode 5 as a bottom electrode, a first amorphous Al 2 o 3 Thin film dielectric layer 4, graphene film 3, second amorphous Al 2 o 3 Thin film dielectric layer 2 and Au electrode 1.

[0034] The bottom electrode can also be Au, Pd, Ag, Cu, Pt, ITO, AZO or FTO, preferably ITO, AZO or FTO. The top electrode can be Au, Al, Ag or Pt, preferably Au.

[0035] The thickness of the bottom electrode is 300-350nm, the first amorphous Al 2 o 3 The thickness of the thin-film dielectric layer 4 is 5-30 nm, preferably 10 nm. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com