Cultivation method and punching equipment for edible fungus in bags

A cultivation method and edible fungus technology, which are applied in the directions of botanical equipment and methods, cultivation and application, can solve the problems of low biological efficiency of punching holes, large base of Tremella fruit body, deep punching and inoculating holes, etc. Reduce the probability of bacterial contamination, improve biological efficiency, and reduce the effect of small flower shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

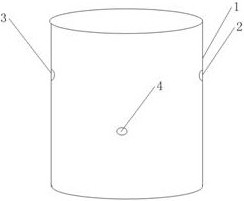

[0078] In Example 1, a total of 4 holes are drilled on two different planes;

[0079] The cultivation method after white fungus bagging comprises the following steps:

[0080] (1) Select a polypropylene bag with a specification of 15×23×0.005cm as the edible fungus fruiting bag, and pack the culture material formula into a bag to form a roughly columnar mushroom fruiting bag; the culture material formula is: 86% cottonseed shell, Bran 10%, lime 3%, gypsum 1%, each bag of dry material weighs 0.6-0.7 kg;

[0081] (2) Select the first group of points on the same circumference of the outer edge of the fruiting bag. The first group of points includes two points. The two selected points are symmetrical about the longitudinal axis passing through the center of the fruiting bag. One point is located at the position of 1 / 3 height from the mouth of the bag to the bottom of the bag;

[0082] Select a second group of points on the same circumference of the outer edge of the fruiting bag...

Embodiment 2

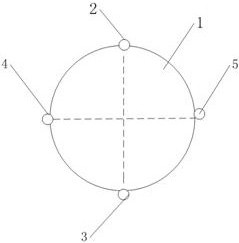

[0093] A total of three holes are punched in embodiment 2, and holes are punched at the edge of the flat fruiting bag at a distance from the fruiting bag mouth 1 / 2 position;

[0094] The cultivation method after white fungus bagging comprises the following steps:

[0095] (1) Select a polypropylene bag with a specification of 15×23×0.005cm as the edible mushroom fruiting bag, and pack the culture material formula into a bag to form a roughly columnar mushroom fruiting bag;

[0096] (2) Select three points on the same circle on the fruiting bag, the angle between adjacent points among the three selected points is 120°, and the distance between adjacent points is equal; the above three points Located at the 1 / 2 height of the fruiting bag from the mouth to the bottom of the bag;

[0097] Paste air-permeable adhesive tape on the above three points, autoclave at 127°C for 3 hours, and cool down;

[0098] (3) Take off the air-permeable tape, and then punch holes in the place where...

Embodiment 3

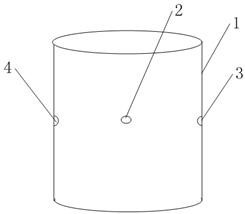

[0104] A total of 6 holes are punched, which are respectively punched on two different planes, and three holes are punched on each plane; and there are two holes distributed on the same longitudinal plane on the fruiting bag;

[0105] The cultivation method after white fungus bagging comprises the following steps:

[0106] (1) Select a polypropylene bag with a specification of 15×23×0.005cm as the edible mushroom fruiting bag, and pack the culture material formula into a bag to form a roughly columnar mushroom fruiting bag;

[0107] (2) Select the first group of points on the same circle on the fruiting bag. The first group of points consists of three points. The angle between adjacent points among the three selected points is 120°, and the adjacent The spacing between the points is equal; the above three points are located at the position of 1 / 3 of the height from the mouth of the bag to the bottom of the bag;

[0108]Then select the second group of points on the same circum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com