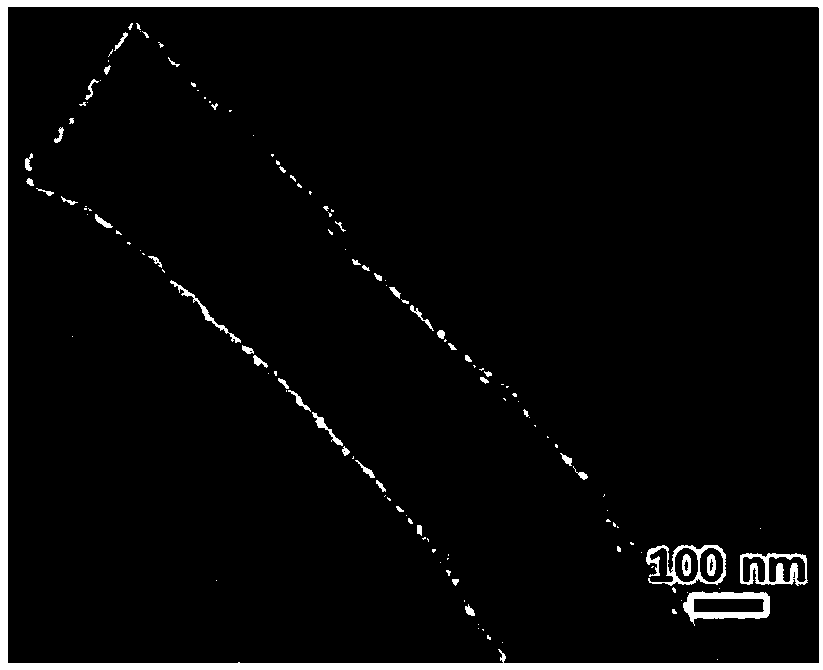

Preparation method of a nanorod-shaped PT/CEO2 supported catalyst and its application in CO catalytic reaction

A supported catalyst and nanorod-shaped technology, which is applied in the field of preparation of nanorod-shaped Pt/CeO2 supported catalysts, can solve the problem that the dispersion and interaction of noble metal Pd nanoparticles cannot be precisely regulated, and achieve broad industrial application prospects, excellent CO Low-temperature catalytic oxidation performance, low loading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Catalyst preparation:

[0026] First add 2.1g of 1,3,5-benzenetricarboxylic acid solid into a mixed solvent of 50mL ethanol and 50mL DMF, stir well until it is completely dissolved to obtain a 1,3,5-benzenetricarboxylic acid solution with a concentration of 100mM, and then add 0.1g PVP solid, continue to stir and mix evenly, add 50mL Ce(NO 3 ) 3 ·6H 2 O in ethanol solution was stirred and reacted at 80°C for 16 hours. After the reaction was completed, the obtained product was centrifuged, washed with ethanol, and dried to obtain a white powder Ce-MOF. Then, 250 mg of the Ce-MOF solid was redispersed in 50 mL of 1 mM H 2 PtCl 6 After stirring, 1.0 g of tetrabutylammonium borohydride was added to carry out the reduction reaction, and the reaction was carried out at room temperature for 30 minutes. After the reaction, the product was centrifuged, washed with ethanol, and dried at 60°C. The product was placed in a muffle furnace, and the temperature was raised to 300°C...

Embodiment 2

[0036] Catalyst preparation:

[0037] First add 1.0g of 1,3,5-benzenetricarboxylic acid solid into a mixed solvent of 50mL ethanol and 50mL deionized water, stir well until it is completely dissolved, and obtain a 1,3,5-benzenetricarboxylic acid solution with a concentration of 47.6mM , then add 0.1g PVP solid, continue to stir and mix evenly, add 50mL, Ce(NO 3 ) 3 ·6H 2 The ethanol solution of O was stirred and reacted at 60° C. for 20 hours. After the reaction was completed, the obtained product was centrifuged, washed with ethanol, and dried to obtain a white powder Ce-MOF. Then, 250 mg of the Ce-MOF solid was redispersed in 50 mL of 1 mM H 2 PtCl 6 After stirring, 1.3 g of tetrabutylammonium borohydride was added to carry out the reduction reaction, and the reaction was carried out at room temperature for 30 minutes. After the reaction, the product was centrifuged, washed with ethanol, and dried at 60°C. The product was placed in a muffle furnace, and the temperature ...

Embodiment 3

[0044] Catalyst preparation:

[0045] First add 2.1g of 1,3,5-benzenetricarboxylic acid solid into a mixed solvent of 50mL ethanol and 50mL DMF, stir well until it is completely dissolved to obtain a 1,3,5-benzenetricarboxylic acid solution with a concentration of 100mM, and then add 0.001g PVP solid, continue stirring and mixing evenly, add 50mL Ce(NO 3 ) 3 ·6H 2 O in ethanol solution was stirred and reacted at 60°C for 24 hours. After the reaction was completed, the obtained product was centrifuged, washed with ethanol, and dried to obtain a white powder Ce-MOF. Then, 250 mg of the Ce-MOF solid was redispersed in 50 mL of 1 mM H 2 PtCl 6 After stirring, 1.3 g of tetrabutylammonium borohydride was added to carry out the reduction reaction, and the reaction was carried out at room temperature for 30 minutes. After the reaction is over, the product is centrifuged, washed with ethanol, and dried. The obtained product is placed in a muffle furnace, and the temperature is rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com