Preparation method for Co-Ni dual-metal-loaded TiO2(B) photocatalysis material and application of photocatalysis material

A photocatalytic material, bimetallic technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, heterogeneous catalyst chemical elements, etc. The problem of easy recombination of holes, etc., can improve the separation and migration rate, reduce the activation energy and overpotential, and improve the stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

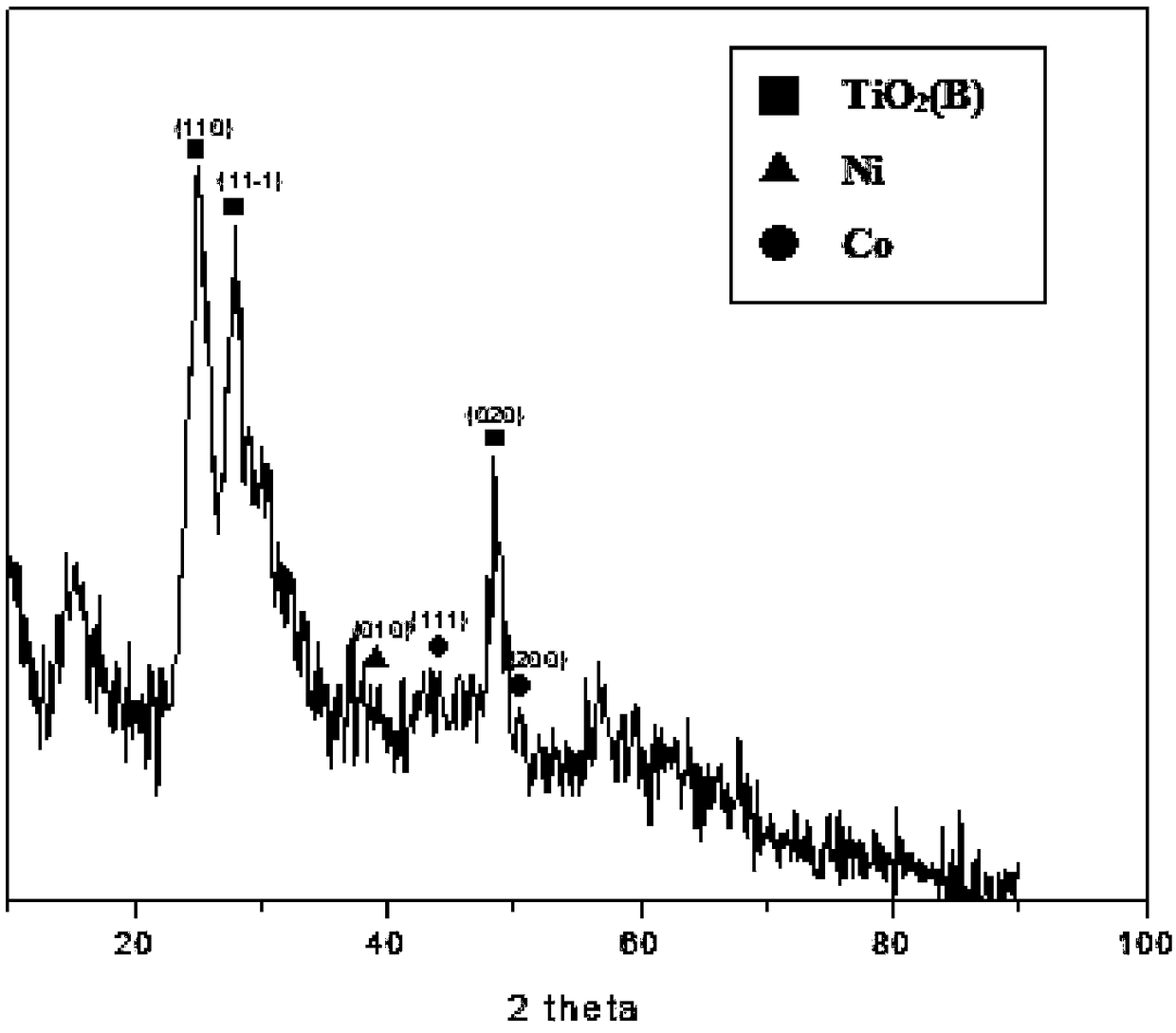

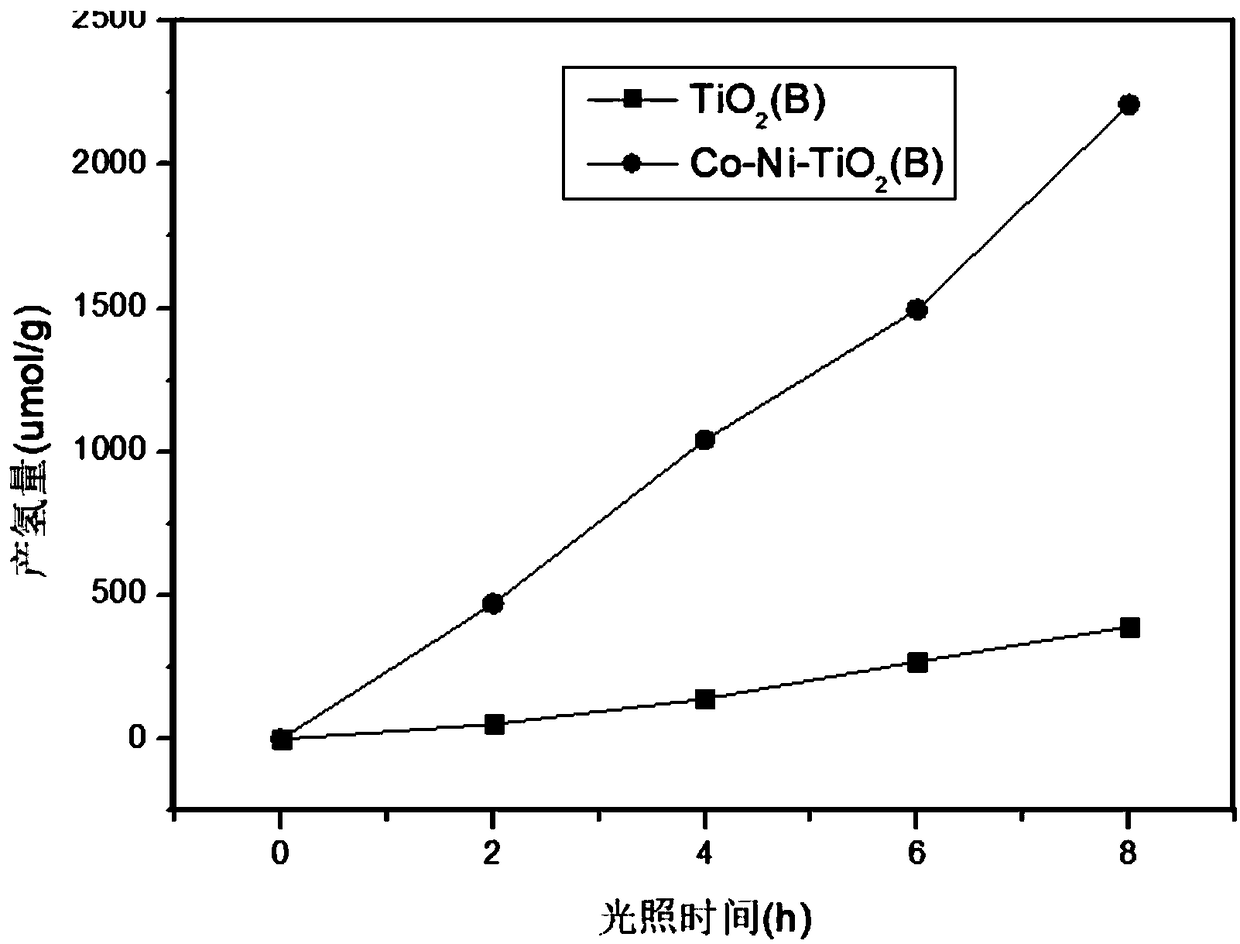

[0031] Preparation of Co-Ni Bimetallic Supported TiO 2 (B) the method for photocatalytic material, its preparation steps are as follows:

[0032] Step 1. Weigh 200mg of TiO 2 (B) and 3mg Ni(NH 3 ) 6 Cl 2 , 3.4mg[Co(NH 3 ) 5 Cl]Cl 2 Put it in a beaker (that is, the atomic ratio of Ni to Ti, Co to Ti is 0.5:100), add 100mL deionized water to the beaker, and ultrasonicate the resulting turbid liquid for 10min to make TiO 2 (B) mix evenly with ammonia compound;

[0033] Step 2, adjusting the pH value of the homogeneous turbid liquid obtained in Step 1 to pH=11 with ammonia water and hydrochloric acid;

[0034] Step 3, place the turbid liquid obtained in Step 2 in an orbital shaker and shake for 1.5h, and shake at a constant temperature to obtain the surface adsorbed Ni(NH 3 ) 6 Cl 2 and [Co(NH 3 ) 5 Cl]Cl 2 TiO 2 (B) turbid liquid;

[0035] Step 4, the TiO obtained in step 3 2 (B) Put the turbid liquid under a 300W xenon lamp and use 150mW / m 3 The light irradiate...

Embodiment 2

[0038] Preparation of Co-Ni Bimetallic Supported TiO 2 (B) the method for photocatalytic material, its preparation steps are as follows:

[0039] Step 1, the atomic ratio of Ni to Ti, Co to Ti is 0.7:100, 200mg of TiO 2 (B) Added Ni(NH 3 ) 6 Cl 2 , [Co(NH 3 ) 5 Cl]Cl 2 4.2 mg and 4.8 mg respectively, that is, the atomic ratios of Ni to Ti and Co to Ti are both 0.7:100. Add 150 mL of deionized water to the beaker, and ultrasonicate the obtained turbid liquid for 7 minutes to make TiO 2 (B) mix evenly with ammonia compound;

[0040] Step 2, adjusting the pH value of the homogeneous turbid liquid obtained in Step 1 to pH=10.8 with ammonia water and hydrochloric acid;

[0041] Step 3, place the turbid liquid obtained in Step 2 in an orbital shaker and shake for 2 hours, and ultrasonically oscillate to obtain the surface adsorbed Ni(NH 3 ) 6 Cl 2 and [Co(NH 3 ) 5 Cl]Cl 2 TiO 2 (B) turbid liquid;

[0042] Step 4, the TiO obtained in step 3 2 (B) The turbid liquid is...

Embodiment 3

[0045] Preparation of Co-Ni Bimetallic Supported TiO 2 (B) the method for photocatalytic material, its preparation steps are as follows:

[0046] Step 1, the atomic ratio of Ni to Ti, Co to Ti is 1:100, 200mg of TiO 2 Ni(NH) added in (B) 3 ) 6 Cl 2 , [Co(NH 3 ) 5 Cl]Cl 2 The amount is 6mg, 6.8mg respectively, that is, the atomic ratio of Ni to Ti, Co to Ti is 1:100. Add 100mL of deionized water to the beaker, and ultrasonicate the obtained turbid liquid for 10min to make TiO 2 (B) mix evenly with ammonia compound;

[0047] Step 2, adjusting the pH value of the homogeneous turbid liquid obtained in Step 1 to pH=11.2 with ammonia water and hydrochloric acid;

[0048] Step 3, place the turbid liquid obtained in step 2 in an orbital shaker and shake for 0.5h, and then you can get Ni(NH) adsorbed on the surface. 3 ) 6 Cl 2 and [Co(NH 3 ) 5 Cl]Cl 2 TiO 2 (B) turbid liquid;

[0049] Step 4, the TiO obtained in step 3 2 (B) The turbid liquid is placed under a 300W hel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com