A preparation device and preparation method of narrowly distributed spherical metal powder for additive manufacturing

A metal powder and additive manufacturing technology, which is applied in the field of spherical metal powder preparation devices, can solve problems such as unsuitable alloy powder, and achieve the effects of improving powder yield, good heat preservation effect, and increasing jet gas velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

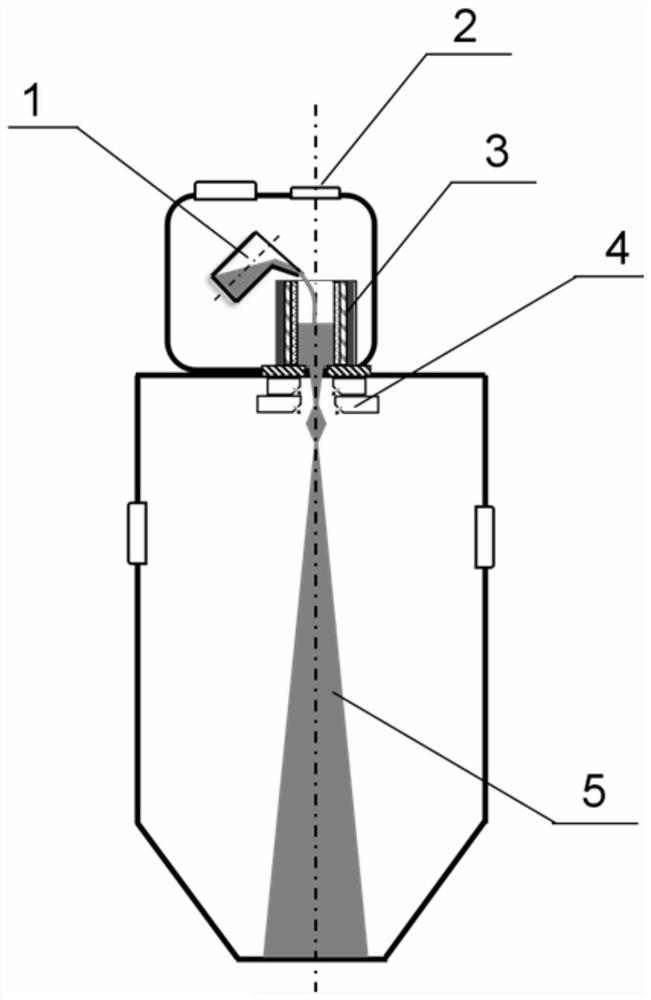

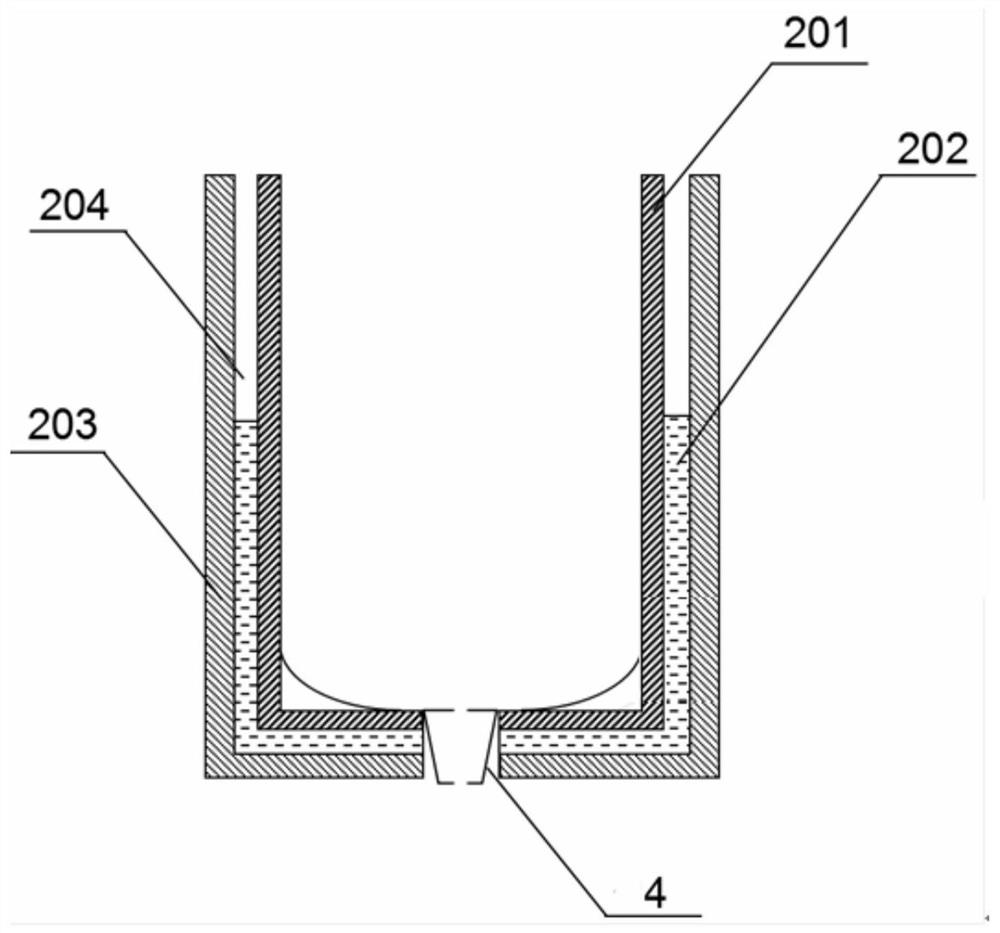

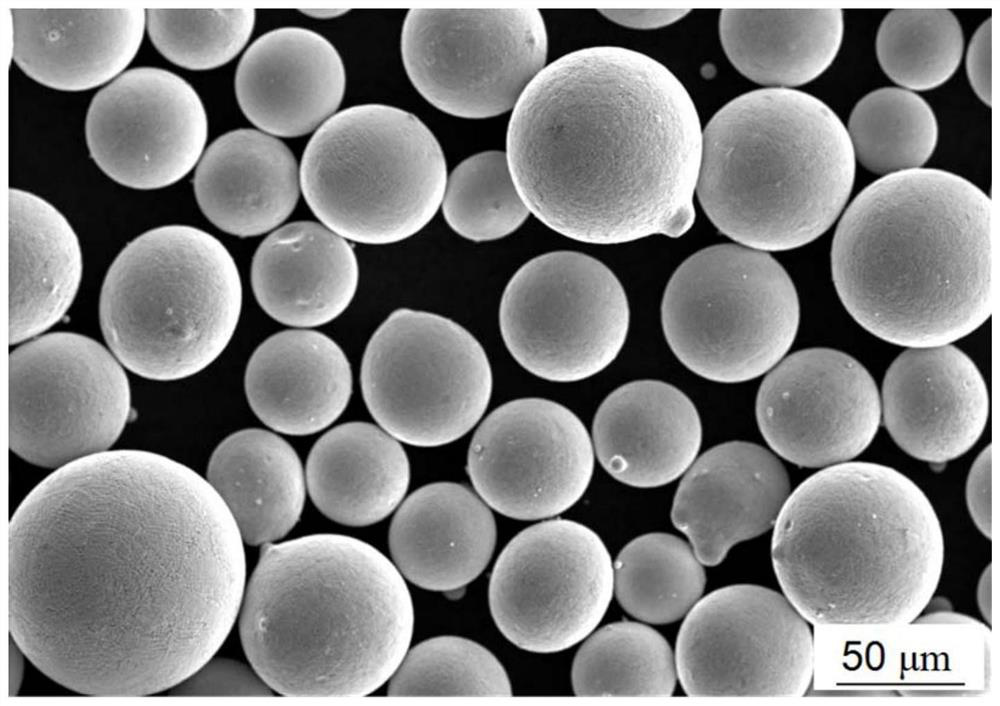

[0039] The supersonic gas atomization method is adopted to change the traditional plugging smelting system and adopt figure 1 The pouring method shown in the pouring crucible shown in the middle is smelting and atomizing, and the level of powder prepared by atomization is increased to 50kg / heat. At the same time, the preparation method of the present invention has the function of infrared temperature measurement, and at the same time, it is calibrated by a thermocouple to realize accurate measurement of the temperature rise in the preparation process. At the same time, the insulation structure of the tundish is as follows: figure 2 As shown, it adopts a layered structure design, the outer layer is a stainless steel sheath, the inner layer is an insulated crucible, and the middle layer is filled with magnesia, with a filling thickness of 0.5-2cm and a height of 15-20cm. The precise control of the temperature ensures that the temperature of the melt is stable during the pouring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com