High-speed laser brazing method for automobile ceiling

A canopy and automobile technology, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of reducing the connection strength between the automobile canopy and the side walls, turbulent molten pool flow, and increasing equipment costs, so as to suppress the fish scale pattern. And the generation of hump weld bead, reduce the higher requirements of laser output power, reduce the effect of increasing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

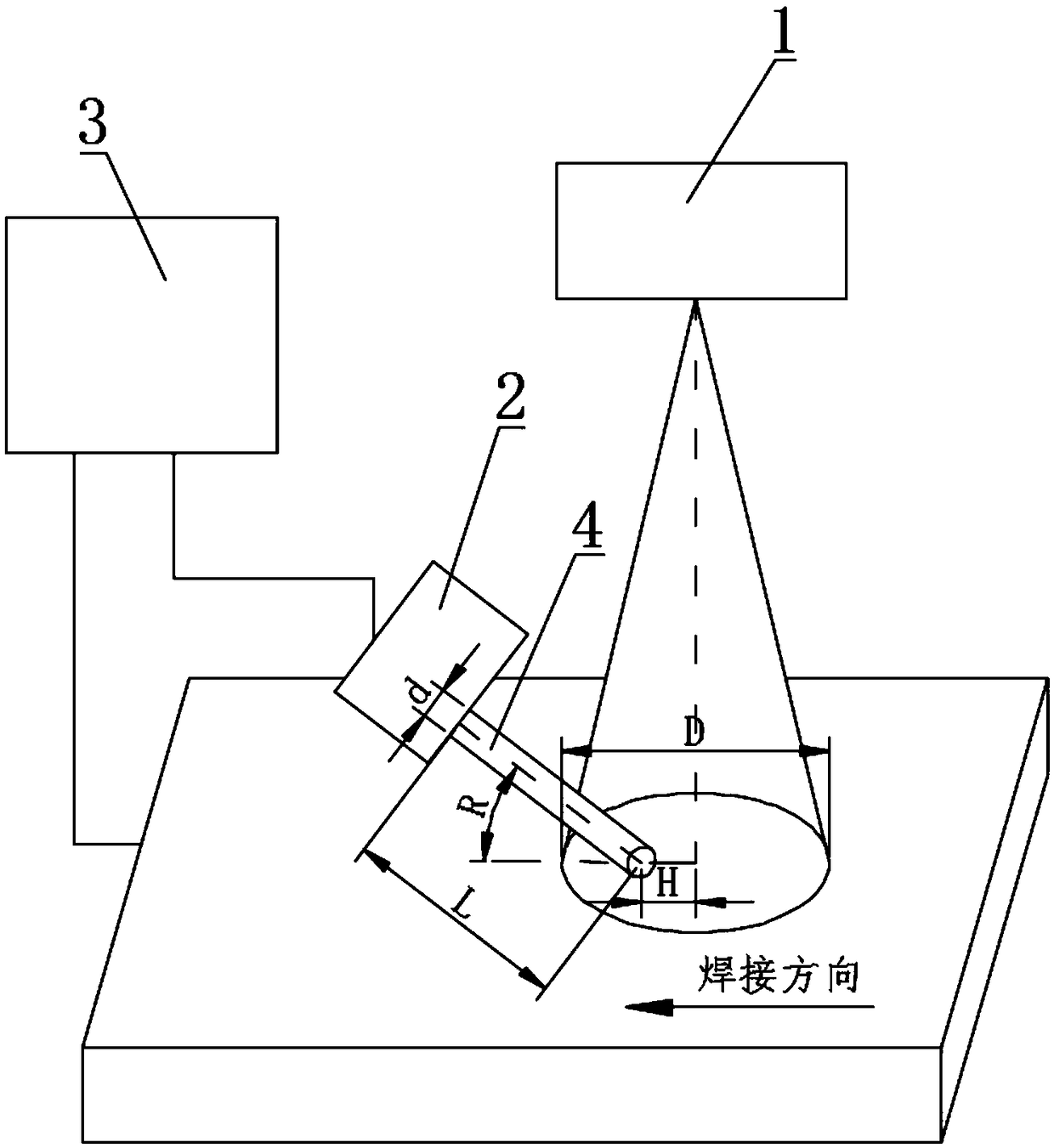

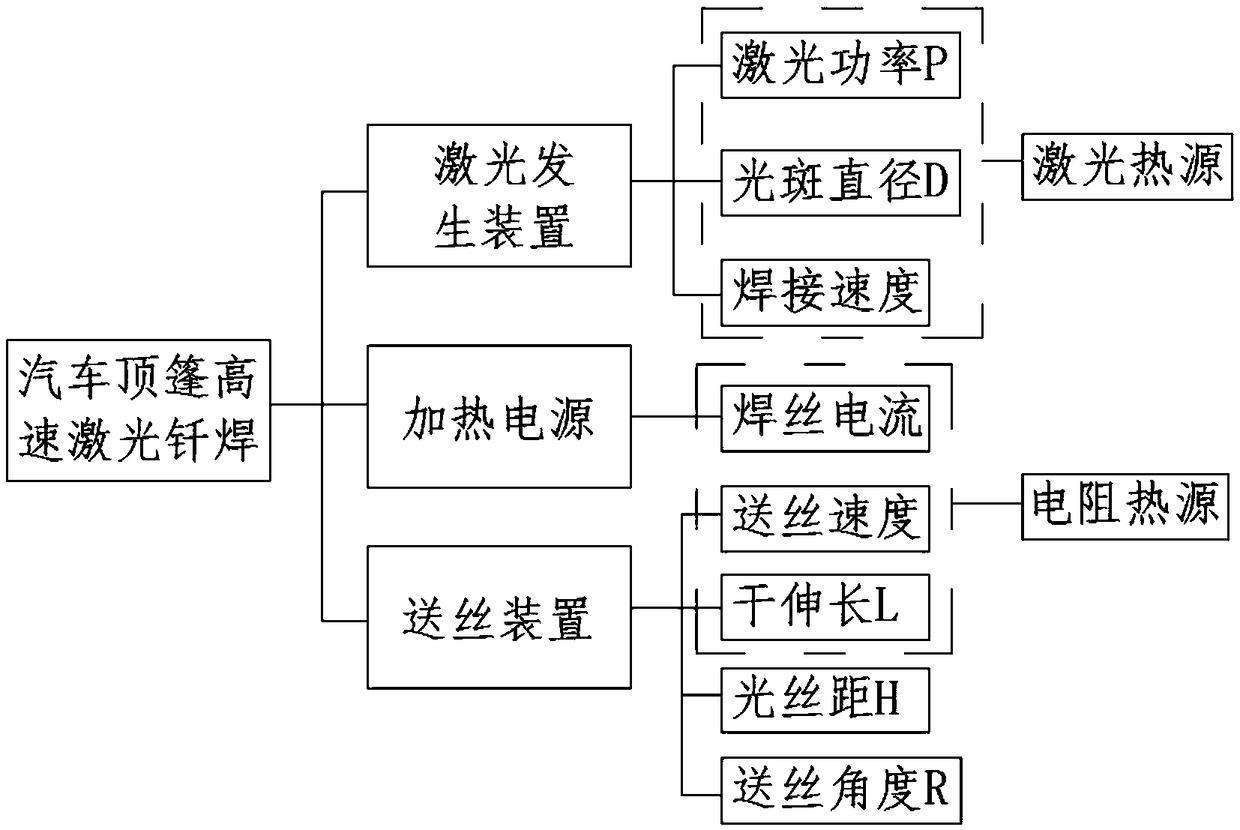

[0035] This embodiment includes a laser generating device 1 , a wire feeding device 2 and a heating power supply 3 for electrical connection with the car roof, and the heating power supply 3 for welding wire 4 is electrically connected to the wire feeding device 2 .

[0036] refer to Figure 1 ~ Figure 4 , the present embodiment provides a method for high-speed laser brazing of an automobile roof, comprising the following steps:

[0037] Step 1: making the welding wire 4 and the car roof electrically connected to the heating power supply, focusing the laser beam generated by the laser generating device 1 on the weld seam of the car roof, and forming a laser spot on the weld seam;

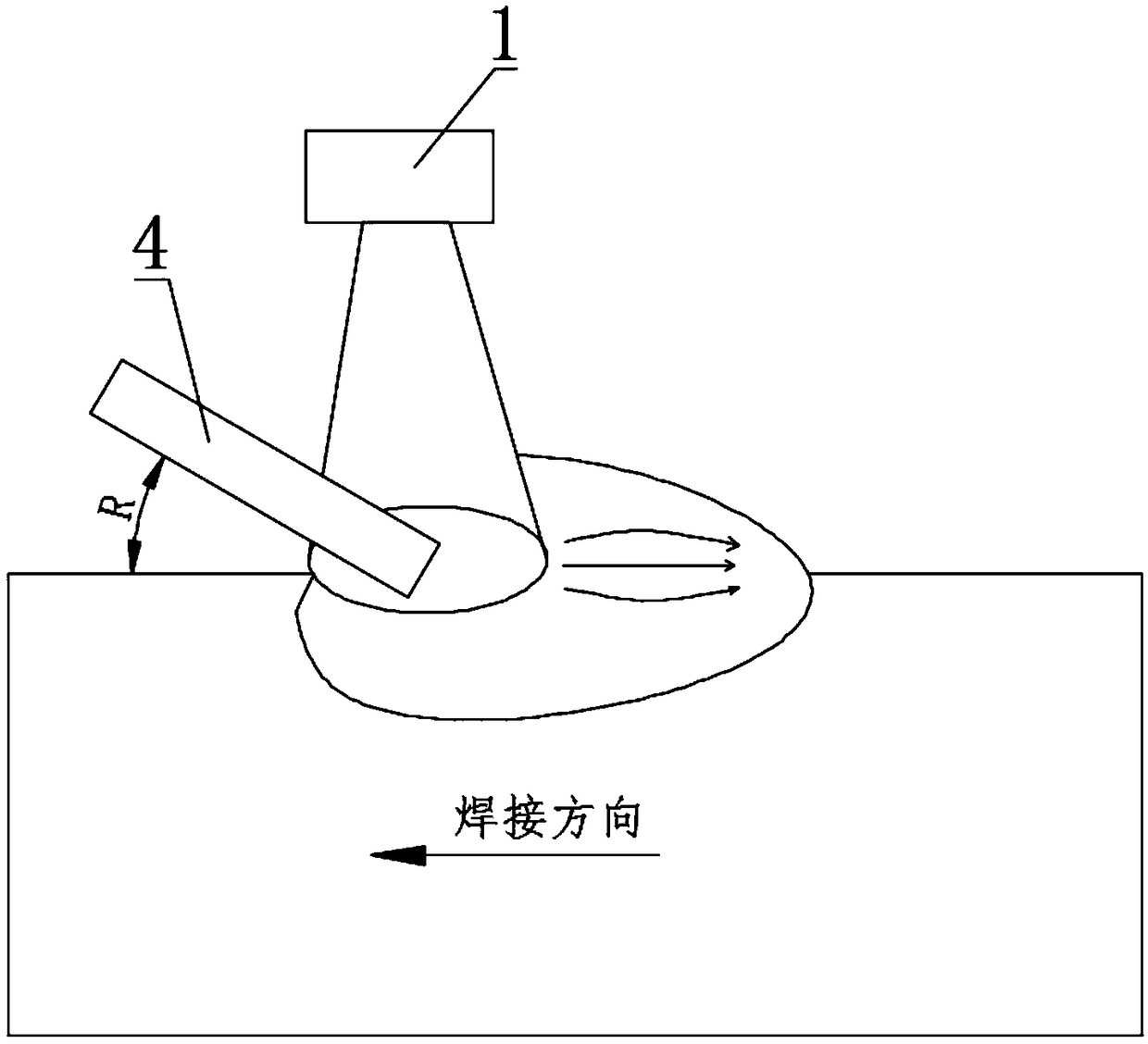

[0038] Step 2: Send the welding wire 4 into the laser spot through the wire feeding device 2. At the same time, the welding wire 4 is in contact with the roof of the car. The contact position of the pool is at the leading edge of the molten pool;

[0039] Step 3: Make the laser spot generated by t...

Embodiment 2

[0054] The difference between this embodiment and the embodiment is that in step 1, the output power P of the laser generator 1 is 4.6-5.9KW, the ratio of the diameter D of the laser spot to the diameter d of the welding wire 4 is D:d=1.5:1, the welding wire The angle formed by the axis of 4 and the moving direction of the welding wire 4 is R=30°, and the ratio of the length L of the welding wire 4 protruding from the wire feeding device 2 to the diameter d of the welding wire 4 is L:d=6:1;

Embodiment 3

[0056] The difference between this embodiment and the embodiment is that in step 1, the output power P of the laser generator 1 is 6KW, and the ratio of the diameter D of the laser spot to the diameter d of the welding wire 4 is D: d=1.7:1, the ratio of the diameter d of the welding wire 4 The angle between the axis and the moving direction of the welding wire 4 is R=25°, and the ratio of the length L of the welding wire 4 protruding from the wire feeding device 2 to the diameter d of the welding wire 4 is L:d=7:1;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com