Multi-layered broadband sound absorption and insulation material and preparation method thereof

A sound-absorbing material and sound-absorbing technology, which is applied in the field of sound-absorbing and sound-insulating materials, can solve the problems of not being able to achieve good sound-absorbing and sound-insulating effects, lack of comfort, rough surface, etc., to solve echoes in the car, improve comfort, and improve The effect of light fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

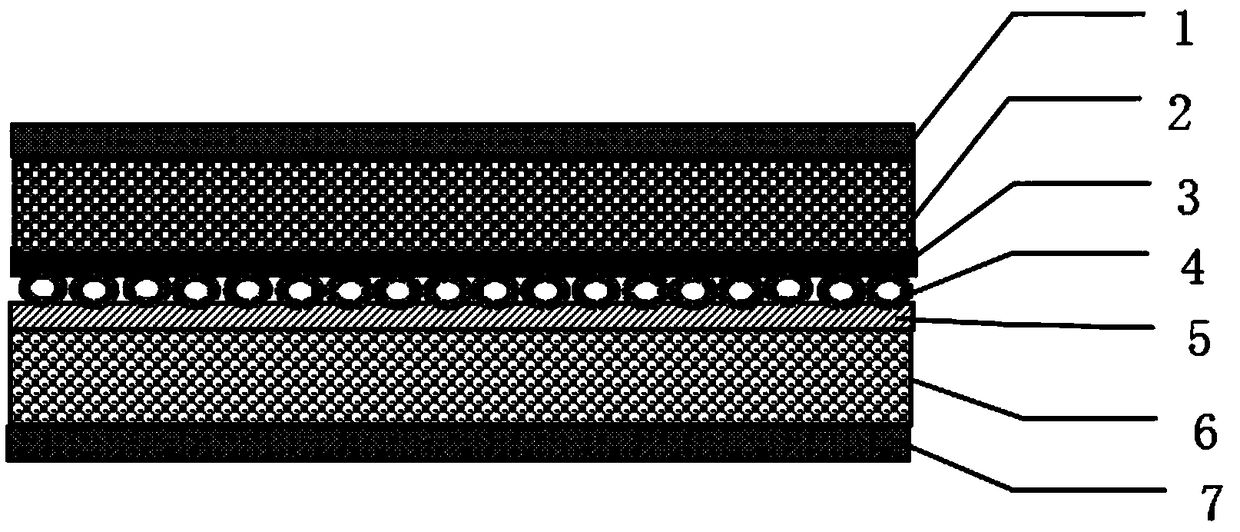

[0037] Such as figure 1 As shown, a multi-layer broadband sound-absorbing and sound-insulating material is composed of seven layers, from top to bottom are non-woven fabric layer 1, rigid porous foam layer 2, plastic film layer 3, hollow glass sphere layer 4, nano Fiber film layer 5, soft porous foam layer 6 and knitted fabric layer 7. The thickness of the multi-layer broadband sound-absorbing and sound-insulating material is 1.2cm.

[0038] The non-woven fabric layer 1 is a non-woven fabric layer 1 formed by thermal bonding of short glass fibers and PU fibers. The non-woven fabric layer 1 is used as the base cloth of a multi-layer broadband sound-absorbing and sound-insulating material. The short glass fibers have a length of 4 mm and a diameter of 15 μm. The length of PU fiber is 4mm, the diameter is 15μm, and the mixing ratio of glass short fiber and PU fiber is 80:20. Both the rigid porous foam layer 2 and the soft porous foam layer 6 are sound-absorbing layers formed by...

Embodiment 2

[0049] Such as figure 1 As shown, a multi-layer broadband sound-absorbing and sound-insulating material is composed of seven layers, from top to bottom are non-woven fabric layer 1, rigid porous foam layer 2, plastic film layer 3, hollow glass sphere layer 4, nano Fiber film layer 5, soft porous foam layer 6, knitted fabric layer 7. The thickness of the multi-layer broadband sound-absorbing and sound-insulating material is 1cm.

[0050] The non-woven fabric layer 1 is a non-woven fabric layer 1 formed by thermal bonding of short glass fibers and PU fibers. The non-woven fabric layer 1 is used as the base cloth of a multi-layer broadband sound-absorbing and sound-insulating material. The short glass fibers have a length of 3 mm and a diameter of 10 μm. The length of PU fiber is 3mm, the diameter is 10μm, and the mixing ratio of glass short fiber and PU fiber is 90:10. Both the rigid porous foam layer 2 and the soft porous foam layer 6 are sound-absorbing layers formed by poly...

Embodiment 3

[0061] Such as figure 1 As shown, a multi-layer broadband sound-absorbing and sound-insulating material is composed of seven layers, from top to bottom are non-woven fabric layer 1, rigid porous foam layer 2, plastic film layer 3, hollow glass sphere layer 4, nano Fiber film layer 5, soft porous foam layer 6, knitted fabric layer 7. The thickness of the multi-layer broadband sound-absorbing and sound-insulating material is 1.5cm.

[0062] The non-woven fabric layer 1 is a non-woven fabric layer 1 formed by thermal bonding of short glass fibers and PU fibers. The non-woven fabric layer 1 is used as the base cloth of a multi-layer broadband sound-absorbing and sound-insulating material. The short glass fibers have a length of 6 mm and a diameter of 20 μm. The length of PU fiber is 6mm, the diameter is 20μm, and the mixing ratio of short glass fiber and PU fiber is 70:30. Both the rigid porous foam layer 2 and the soft porous foam layer 6 are sound-absorbing layers formed by po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap