Bogie cleaning equipment

A technology for cleaning equipment and bogies, applied in vehicle cleaning equipment, vehicle cleaning, railway cleaning devices, etc., can solve the problems of manual secondary cleaning, incomplete cleaning, residual cleaning water, etc., and achieve a high degree of automation and cleaning effect. Good, low-cost results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

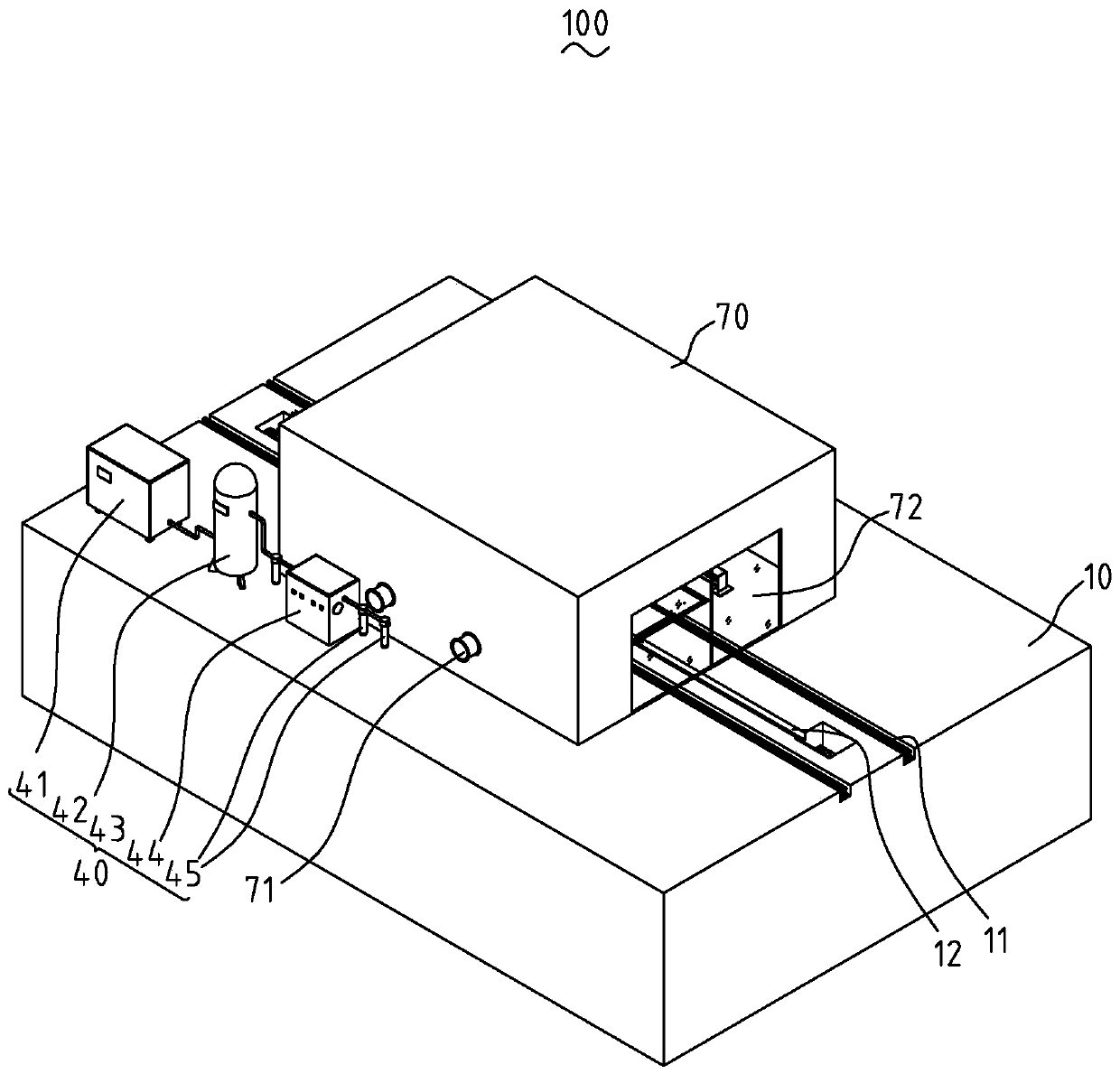

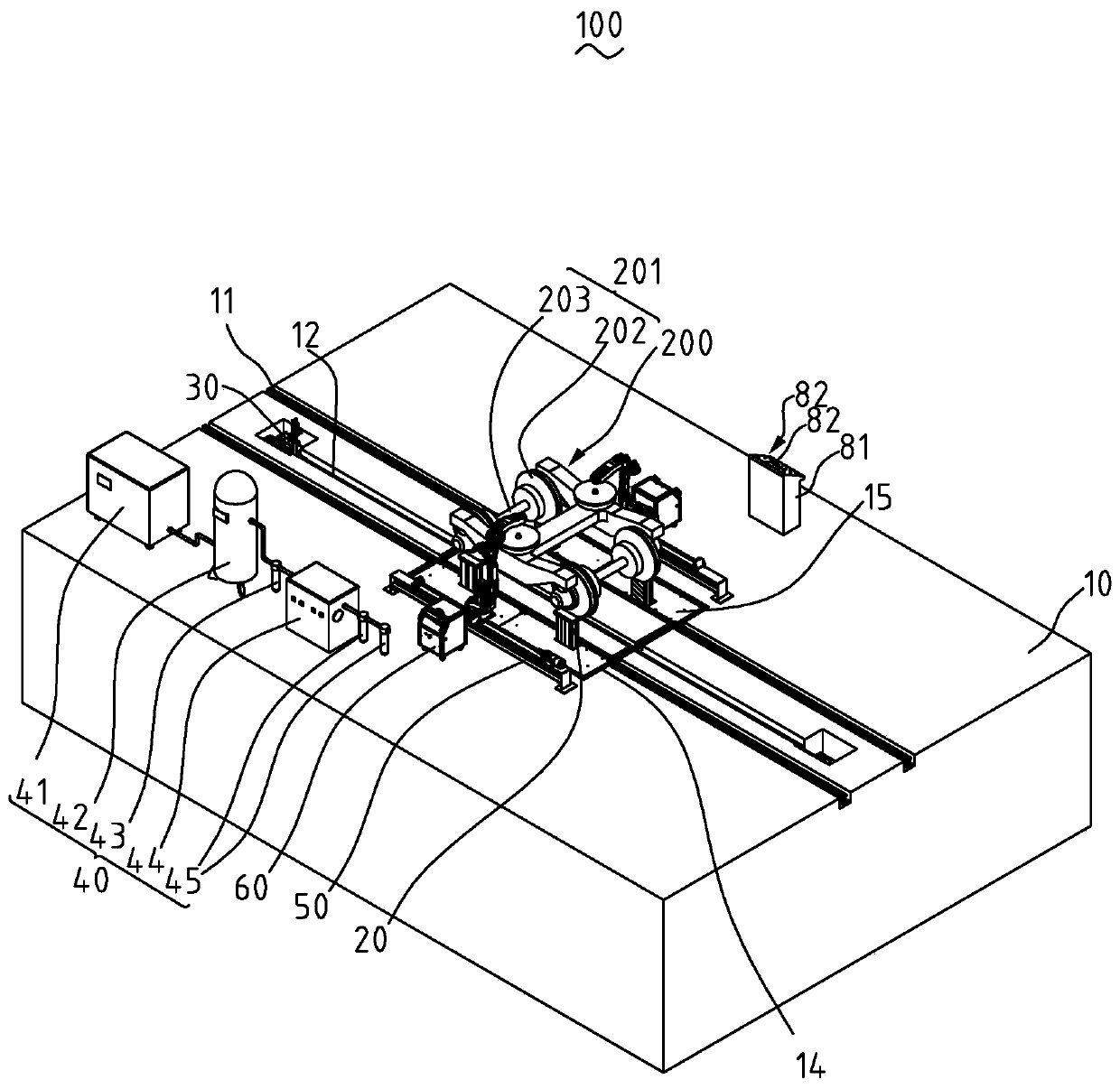

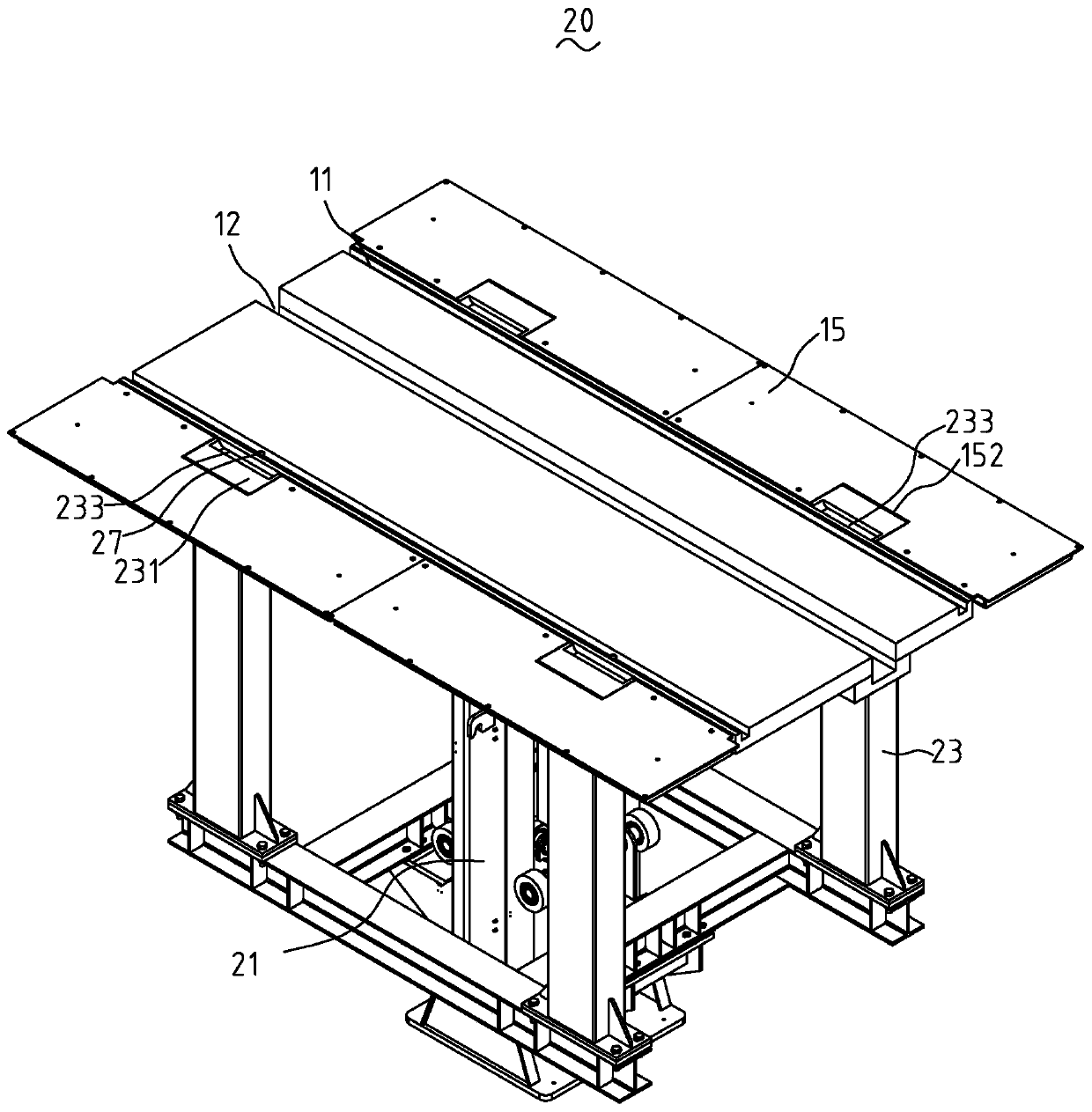

[0028] See Figure 1 to Figure 11 As shown, the bogie cleaning equipment 100 of the present invention includes a table body 10 , a lifting device 20 , a conveying device 30 , a compressed air system 40 , a manipulator 50 , a dry ice blasting device 60 , a cover 70 , and a monitoring and electrical control system 80 . For ease of description, in addition to the bogie cleaning equipment 100, the specification also includes a bogie 200. The bogie 200 includes two wheel pairs 201, front and rear. . The bogie cleaning equipment 100 can clean the bogie 200 and the wheel set 201 disassembled from the bogie, but is not limited thereto.

[0029] The platform body 10 is used for installing other components of the bogie cleaning equipment 100 . The plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com