Preparation method of modified polysulfide sealant

A polysulfide sealant, modified technology, applied in the field of sealants, can solve the problems of poor bonding performance and elongation at break of polysulfide sealant, achieve good bonding strength and elongation at break, and increase application performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

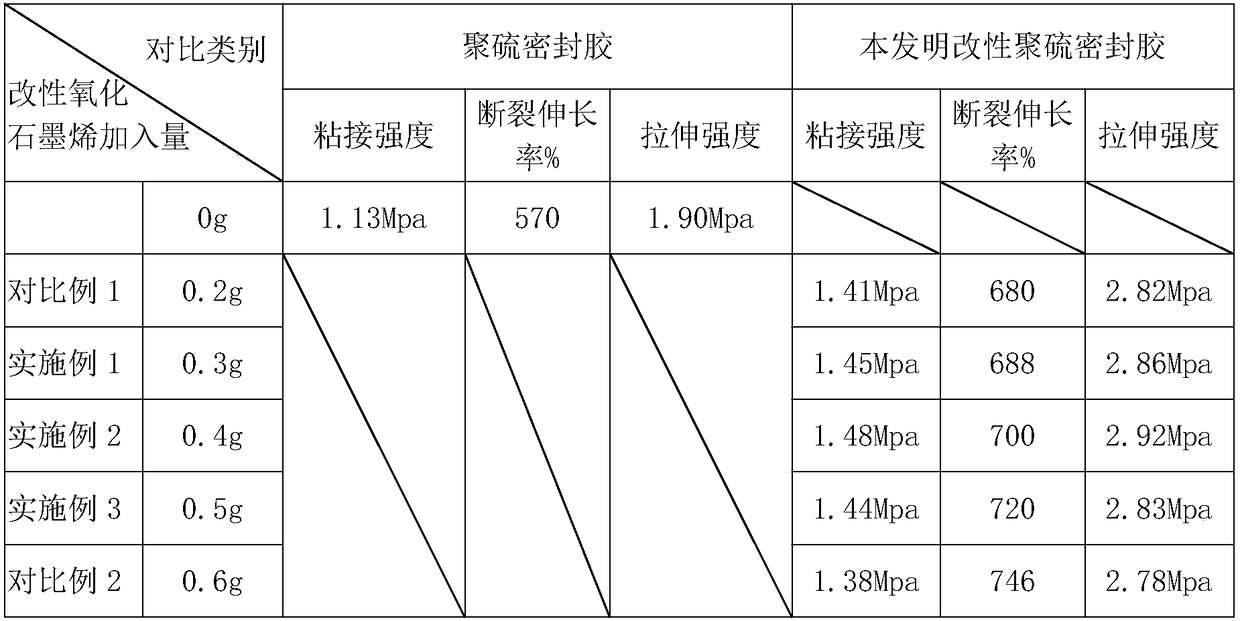

Embodiment 1

[0021] (1) Preparation of modified graphene oxide; preparation of modified graphene oxide using silane coupling agent γ-aminopropyltriethoxysilane and graphene oxide;

[0022] (2) preparing a dispersion liquid; adding 0.3 g of modified graphene oxide prepared in step (1) to 20 g of butyl benzyl phthalate solution and then performing ultrasonic dispersion treatment;

[0023] (3) Prepare the main agent; add 100g of nano calcium carbonate, 6g of carbon black, 10g of phenolic resin, 1g of coupling agent and the solution containing 20g of butyl benzyl phthalate prepared in step (2) into 200g of liquid polysulfide rubber After mixing the dispersion liquid, obtain a paste, and then repeatedly grind it with a three-roll mill until the color of the paste is uniform and bright;

[0024] (4) Preparation of hardener; 20g active manganese dioxide powder, 15g butyl benzyl phthalate and 2g diphenylguanidine are mixed uniformly and then ground using a three-roll mill;

[0025] (5) After mixing the ma...

Embodiment 2

[0027] (1) Same as step (1) in Example 1;

[0028] (2) preparing a dispersion liquid; adding 0.4 g of the modified graphene oxide prepared in step (1) to 20 g of butyl benzyl phthalate solution and then performing ultrasonic dispersion treatment;

[0029] (3) Same as step (3) in Example 1;

[0030] (4) Same as step (4) in Example 1;

[0031] (5) Same as step (5) in Example 1.

Embodiment 3

[0033] (1) Same as step (1) in Example 1;

[0034] (2) preparing a dispersion liquid; adding 0.5 g of modified graphene oxide prepared in step (1) to 20 g of butyl benzyl phthalate solution and then performing ultrasonic dispersion treatment;

[0035] (3) Same as step (3) in Example 1;

[0036] (4) Same as step (4) in Example 1;

[0037] (5) Same as step (5) in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com