Method for gob side entry retaining in top-cutting pressure relief roadway in U-shaped steel support roadway

A technology of roof cutting, pressure relief, and roadway retention, which is applied in tunnels, tunnel linings, and earthwork drilling and mining, and can solve problems such as the difficulty of using active support with anchor nets, lack of U-shaped steel support, and broken surrounding rocks. Achieve good social and economic benefits, low cost, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

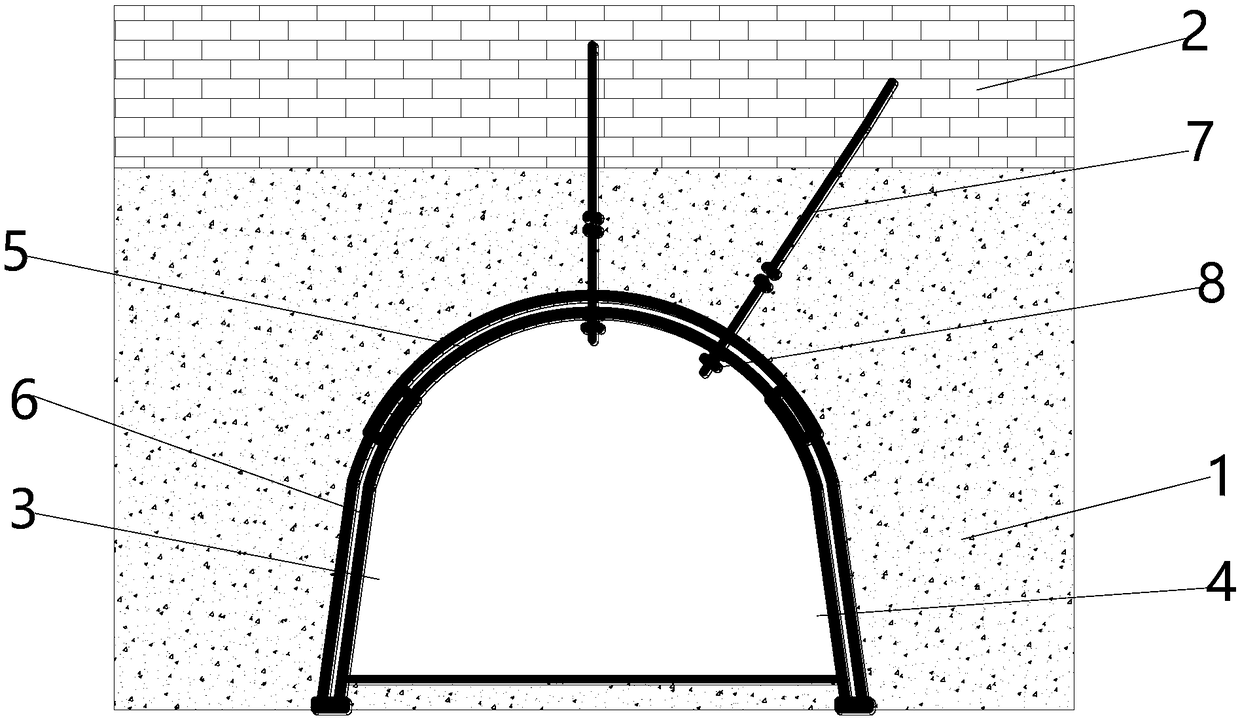

[0036] Step 1) The final structure is: coal seam 1 and the U-shaped steel shed roof beam 5 arranged longitudinally through the interior of the lower half of the U-shaped steel shed roof beam 5. The upper end of the U-shaped steel roof beam 5 is horizontally provided with a roof 2, and the U-shaped steel roof beam and shed legs 6 on the left and right sides are respectively provided with the upper side of the roadway 3 and the lower side of the roadway 4, and the upper end of the U-shaped steel roof beam 5 is uniformly provided with a number of 1 and the anchor cable 7 of the roof 2;

Embodiment 2

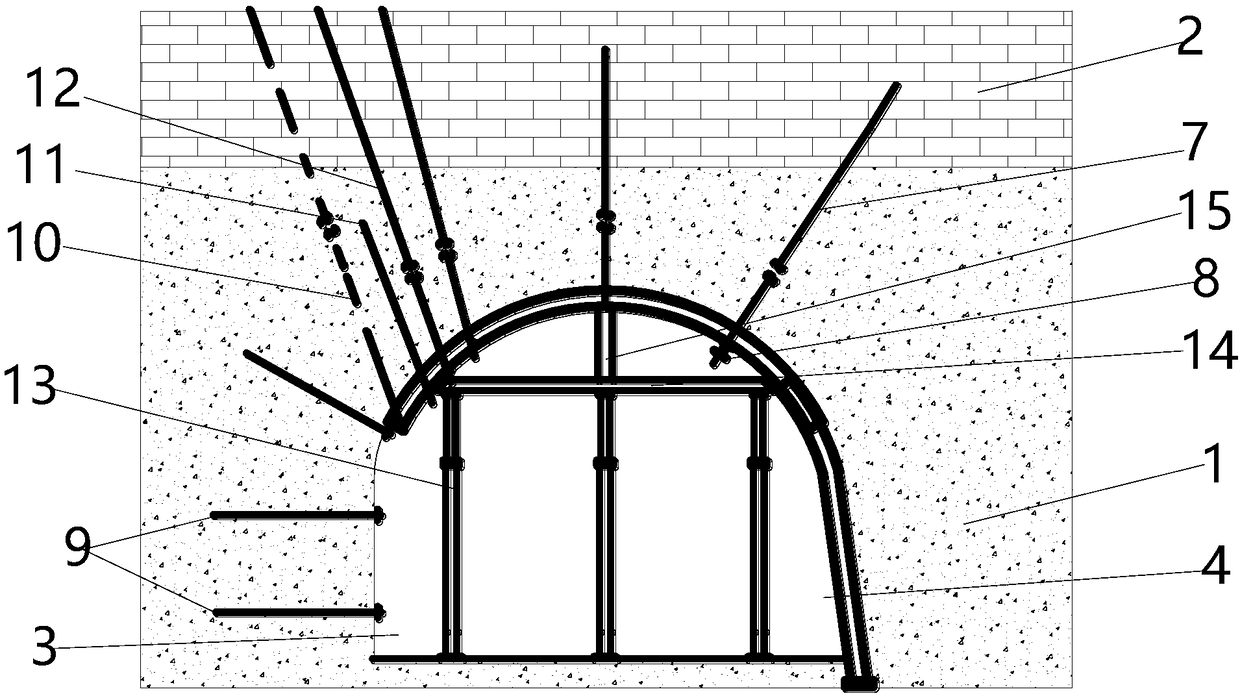

[0038] Step 5) The final structure is: the coal seam 1 and the U-shaped steel shed roof beam 5 arranged longitudinally through the lower half of the interior, the upper end of the coal seam 1 is horizontally provided with a roof 2, and the coal seam 1 on the lower side of the U-shaped steel shed roof beam 5 is about The upper side of the roadway 3 and the lower side of the roadway 4 are respectively arranged, and the upper side of the roadway 3 is horizontally arranged in the coal seam 1 on the left side with a glass fiber reinforced plastic anchor rod 9, and the half section of the U-shaped steel ceiling beam 5 penetrates the coal seam 1 and the roof 2 from the left To the right, there are top-cutting and pressure-relief boreholes 10, equal-strength anchor rods 11, and top-cutting anchor cables 12. The U-shaped steel roof beams 5 on the right side of the top-cutting anchor cables 12 go deep into the coal seam 1 and the roof 2 at equal intervals. A number of anchor cables 7, th...

Embodiment 3

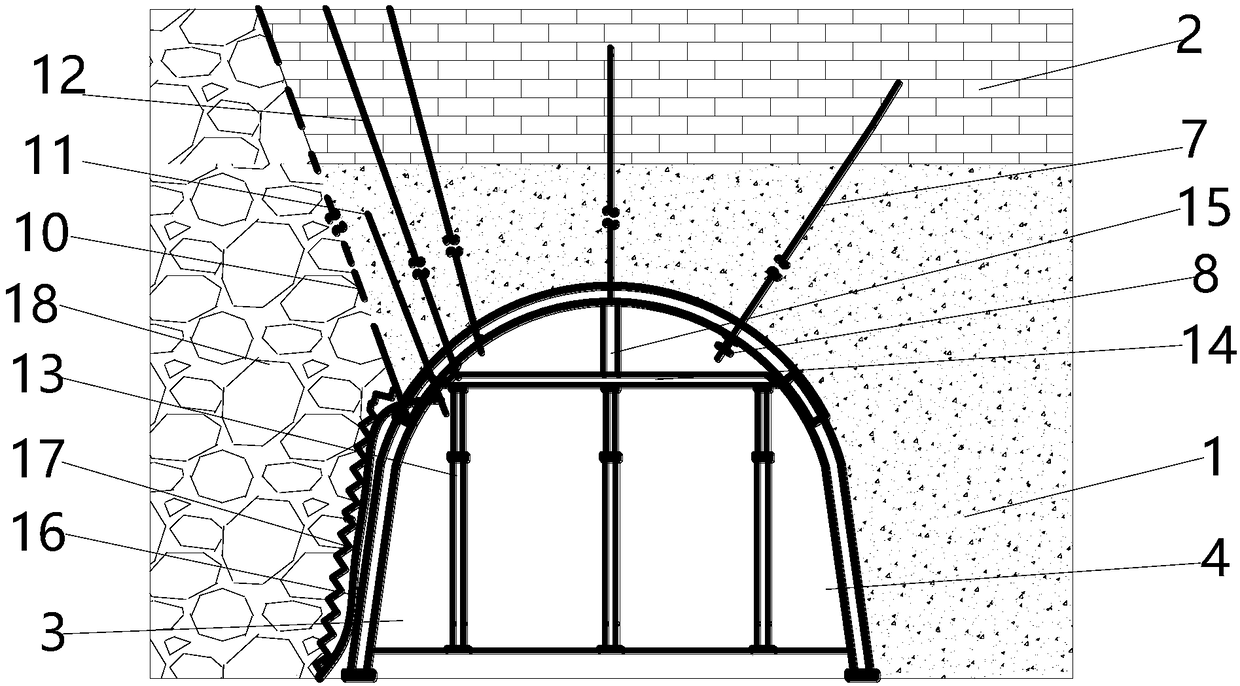

[0040] Step 7) The final structure is: the coal seam 1 and the U-shaped steel shed roof beam 5 installed longitudinally through the lower half of the coal seam 1. The upper side of the roadway 3 and the lower side of the roadway 4 are respectively arranged, and the half section of the U-shaped steel roof beam 5 runs through the coal seam 1 and the roof 2 from left to right. Top-cutting anchor cable 12, goaf 18 is set on the left side of top-cutting pressure relief borehole 10 and roadway upper side 3, and steel wire rope 16 and rhombus net 17 are arranged on the left side of roadway upper side 3, and top-cutting anchor cable 12 The U-shaped steel roof beams 5 on the right side are arranged at equal intervals to go deep into the coal seam 1 and the roof 2, and a number of anchor cables 7 are arranged. The middle position of the lower half of the U-shaped steel roof beams 5 is horizontally provided with π-shaped beams 14, and the π-shaped beams 14 are equidistant and vertically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com