Strike suffocation energy-saving flame extinguishing device and control method

A flame extinguishing and controller technology, applied in the direction of charging system, fuel air inlet, engine components, etc., can solve problems such as insufficient power, insufficient air intake, poor ventilation capacity of metal plate or mesh flame arresters, etc. Achieve the effect of reducing oxygen concentration and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

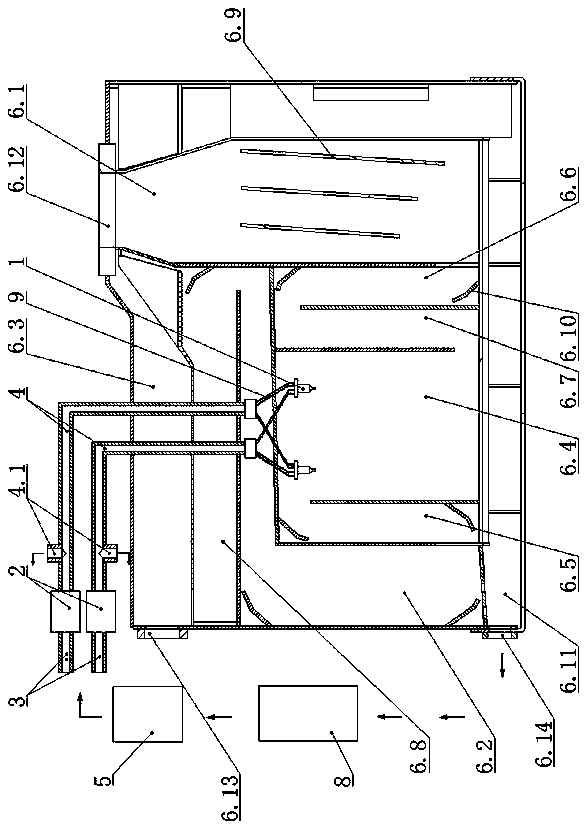

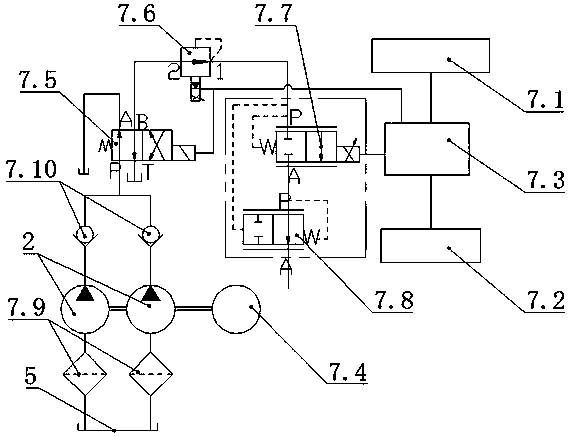

[0027] This embodiment provides an energy-saving flame extinguishing device for impact suffocation, such as figure 1 and figure 2 As shown, it includes housing, water mist nozzle 1, integrated control device, explosion-proof water pump 2, low-pressure main pipe 3, high-pressure main pipe 4 and water tank 5; the air intake chamber 6.1 communicating with the air is arranged in the housing, and the air intake chamber 6.1 The connected flame extinguishing chamber, the water mist cooling chamber 6.2 connected with the flame extinguishing chamber, and the air outlet chamber 6.3 connected with the water mist cooling chamber 6.2; The minimum is 1MPa to ensure that the water has sufficient pressure in the water mist nozzle 1 to generate water mist; the integrated control device includes an oxygen concentration sensor 7.1 for detecting the oxygen concentration in the flame extinguishing chamber, and a sensor for detecting the temperature in the flame extinguishing chamber Temperature ...

Embodiment 2

[0044] This embodiment provides a control method of an impact suffocation energy-saving flame extinguishing device, implemented on the basis of the impact suffocation energy-saving flame extinguishing device described in Embodiment 1, including the following steps:

[0045] S1, detecting the oxygen concentration and temperature in the flame extinguishing chamber;

[0046] S2, if the detected values of oxygen concentration and temperature are within the preset range, the controller 7.3 does not output electricity to the explosion-proof electromagnetic reversing valve 7.5, the explosion-proof electric proportional pressure reducing valve 7.6, the explosion-proof electric proportional flow valve 7.7 and the pressure compensation valve 7.8. Signal; the P port and the A port of the explosion-proof electromagnetic reversing valve 7.5 are connected, and the water provided by the explosion-proof water pump 2 flows back to the water tank 5 through the P port and the A port of the expl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com