Automatic feeding device for silicon smelting furnace and application method thereof

A technology of automatic feeding device and smelting furnace, which is applied to furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of high maintenance cost, frequent replacement of parts, and long transformation cycle, and achieves low maintenance cost and wide distribution range. , the effect of short transformation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

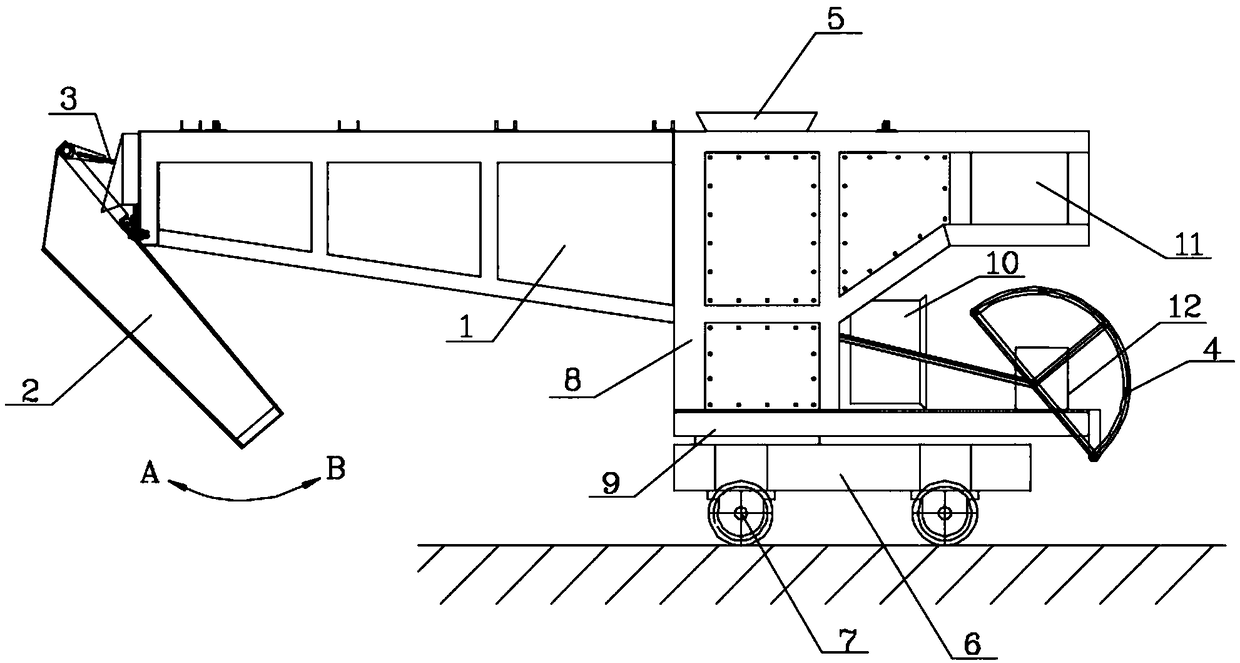

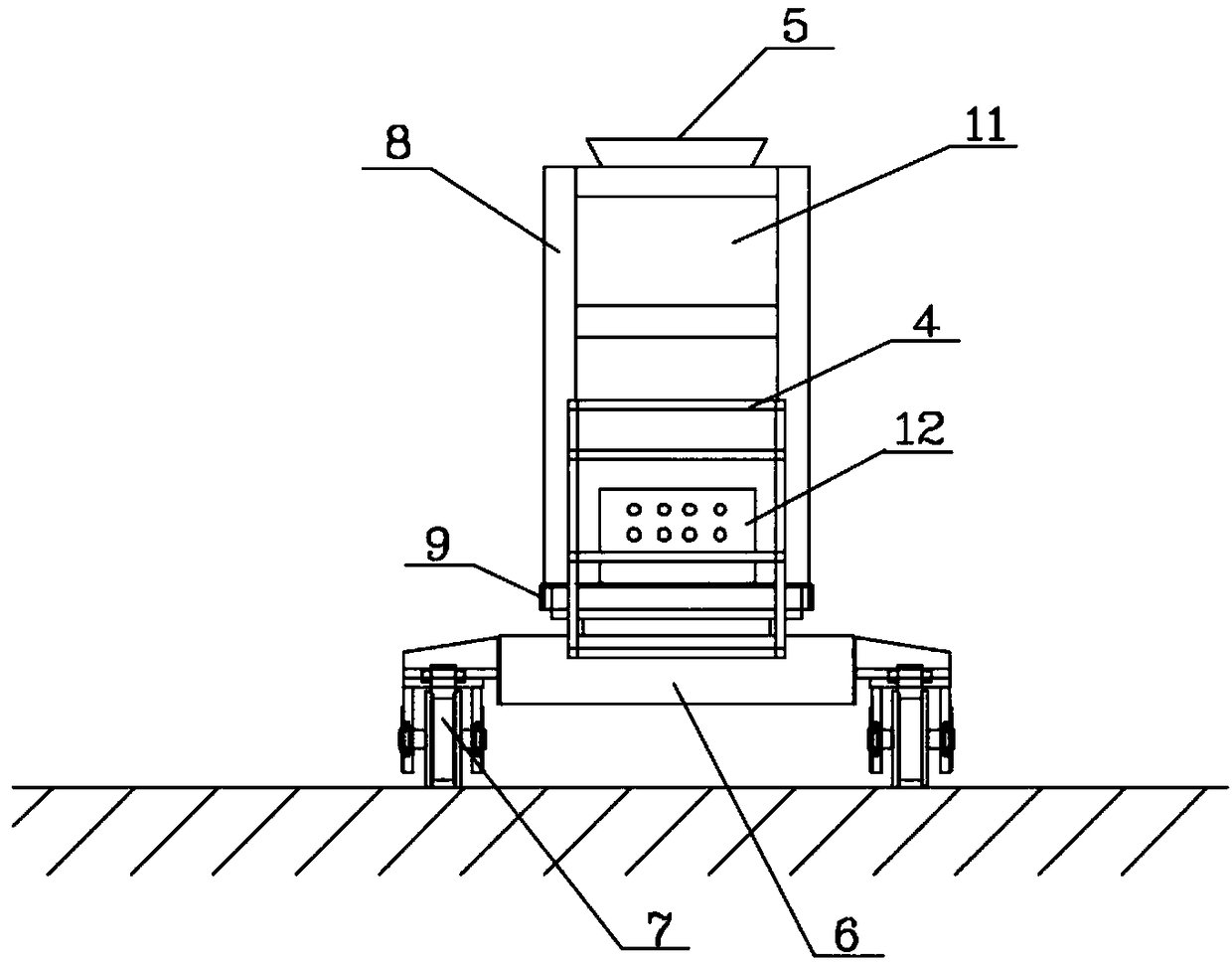

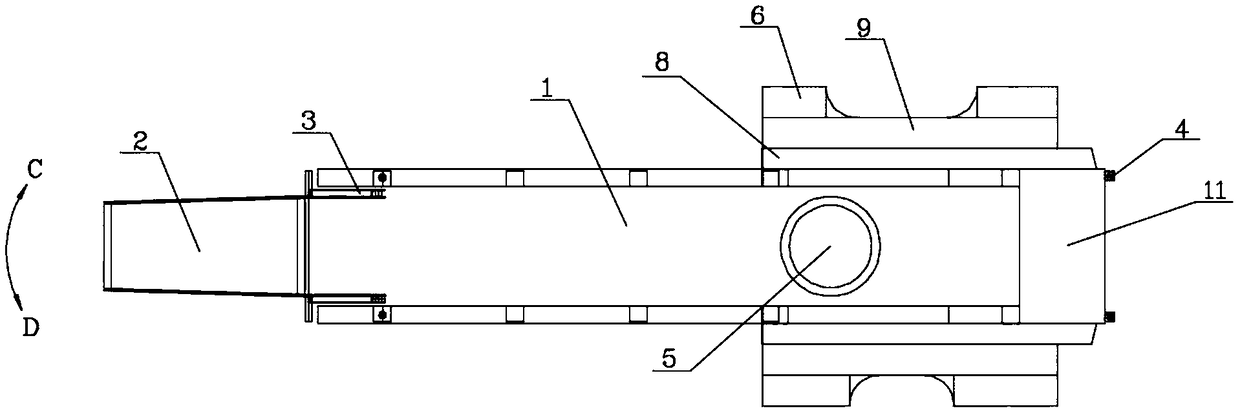

[0033] like Figure 1-Figure 3As shown, when using the present invention to charge the smelting furnace, the staff starts the control box 12, and the control box 12 starts the corresponding power system that is arranged on the vehicle frame 6, and the power system drives the travel wheel 7 to rotate, and the rotation of the travel wheel 7 Drive the movement of vehicle frame 6, because support 8, automatic feeding device 1, operating handle 4, rotating device 9, blower fan 5 are all arranged on the vehicle frame 6, vehicle frame 6 drives support 8, automatic The feeding device 1, the operating handle 4, the rotating device 9, and the fan 5 move to the smelting furnace. When the frame 6 moves to the feeding position, the power system stops working, and the control box 12 opens the feeding port 5, and the ingredients pass through the feeding port. 5 Enter the automatic feeding device 1, the automatic feeding device 1 conveys the ingredients to the material distribution device 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com