High-temperature polymer electrolyte membrane fuel cell

An electrolyte membrane and fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of narrow microbial activity temperature range, harsh living environment, and low conversion rate, so as to increase the reduction rate and improve resource utilization Use and overcome the effect of high overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

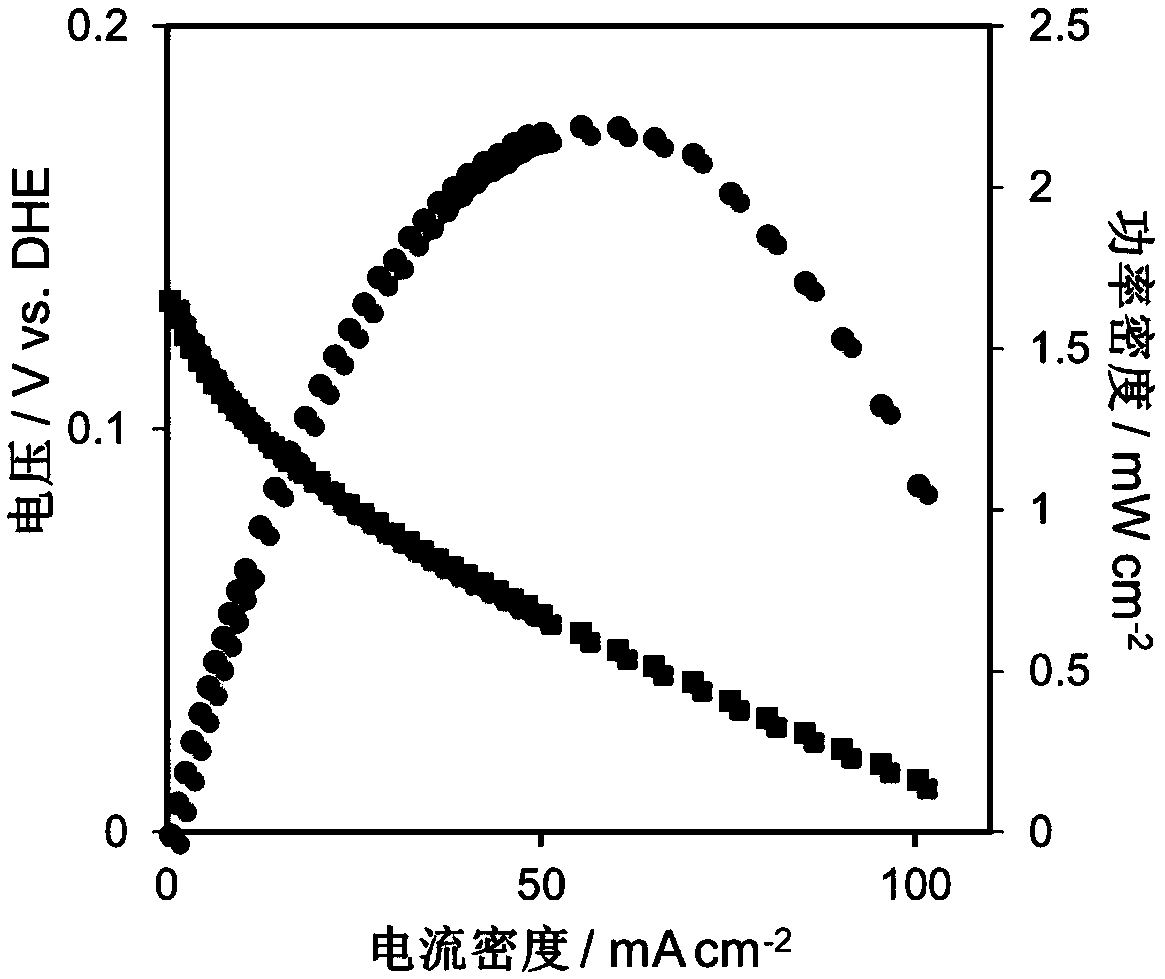

Embodiment 1

[0033] Example 1, a high-temperature polymer electrolyte membrane fuel cell, including a front plate, a bipolar plate, a membrane electrode and a rear end plate; the bipolar plate and the membrane electrode can be stacked as a repeating unit with the front end plate and the rear end plate to form a high temperature polymerization Electrolyte membrane fuel cell stack; the anode uses hydrogen as fuel, and the cathode uses carbon dioxide as fuel; the membrane electrode includes a high-temperature polymer electrolyte membrane and cathode gas diffusion electrodes on both sides of the high-temperature polymer electrolyte membrane; the high-temperature polymer electrolyte membrane It is an acid doped high temperature resistant film;

[0034] The preparation method of the membrane electrode in the fuel cell is as follows:

[0035] Step 1, treatment of the gas diffusion back layer: Toray TGP-H-90 carbon paper is selected as the gas diffusion back layer, and it is subjected to hydrophobic...

Embodiment 2

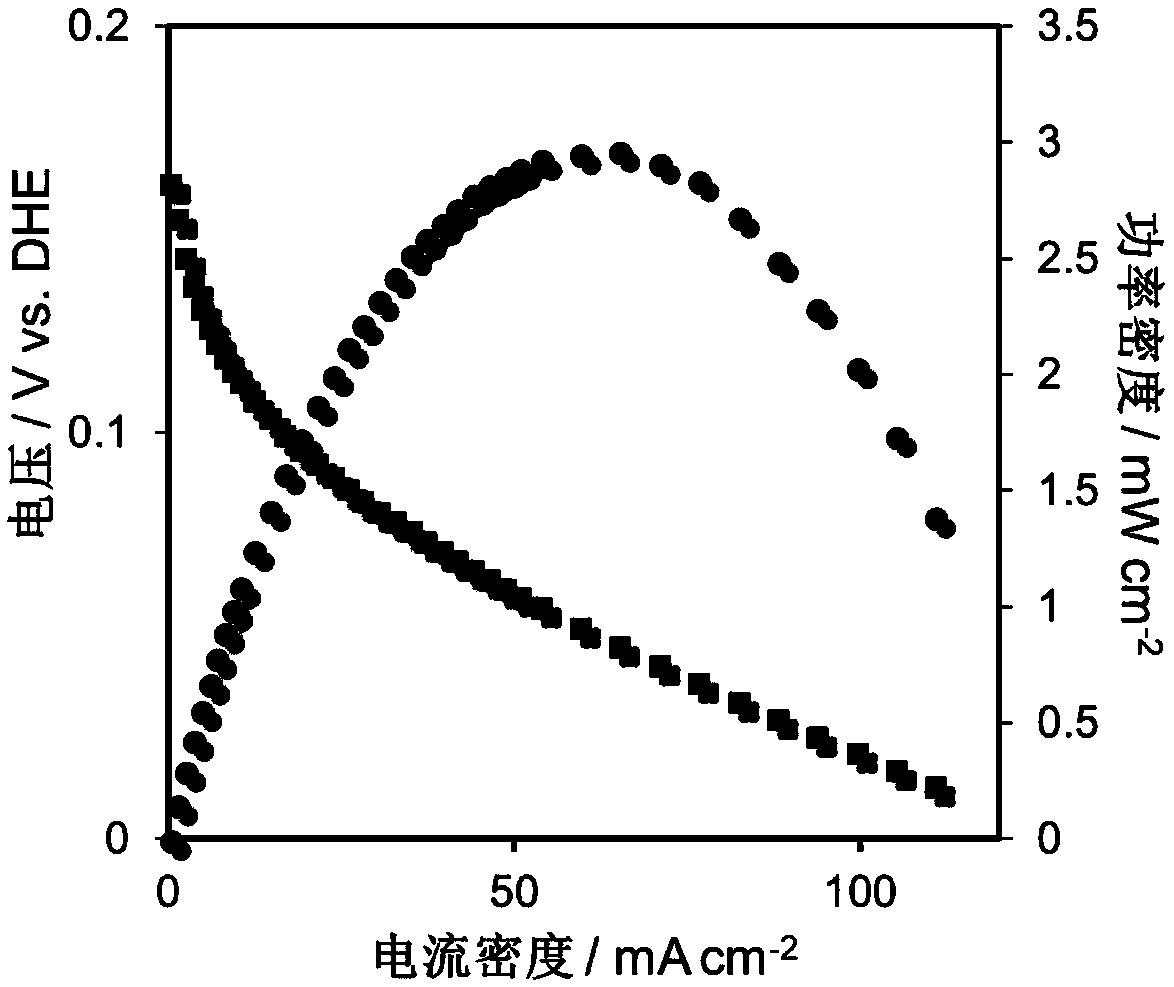

[0046] Example 2, using the same materials and methods as in Example 1, the battery operating temperature was increased to 160 ° C, and the rest of the test conditions were the same, such as figure 2 As shown, the current density of the battery can reach 14.35mA / cm under the working voltage of 0.1V 2 , the maximum power density reaches 2.97mW / cm 2 , the conversion rate of carbon dioxide was 49%.

Embodiment 3

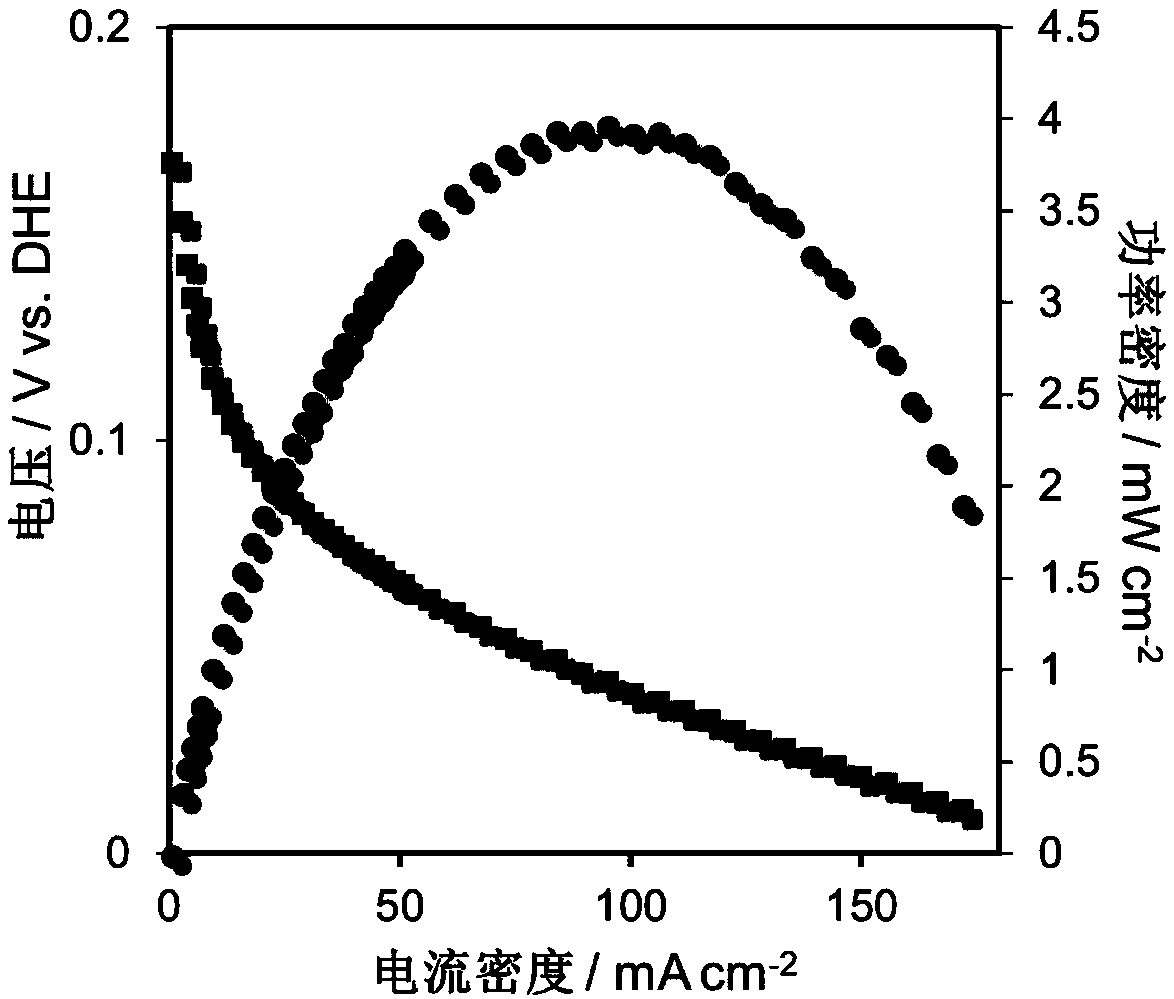

[0047] Example 3, use Pt-Ru / C (Pt: 32.6wt%, Ru: 16.9wt%; Tanaka Kikinzoku Kogyo Co., Ltd.) catalyst in the catalytic layer of the cathode gas diffusion electrode, and the rest are used as in Example 1 Same material and method, adopt the test condition identical with embodiment 1, as image 3 As shown, the current density of the battery can reach 17.6mA / cm under the working voltage of 0.1V 2 , the maximum power density reaches 3.96mW / cm 2 , the conversion rate of carbon dioxide was 56%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com