Battery thermal management system and control method

A battery thermal management and battery technology, applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems of low external heat dissipation, low heat dissipation and temperature uniformity efficiency, high energy consumption, etc., to improve space utilization , improve the performance of the vehicle, and improve the effect of synergy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

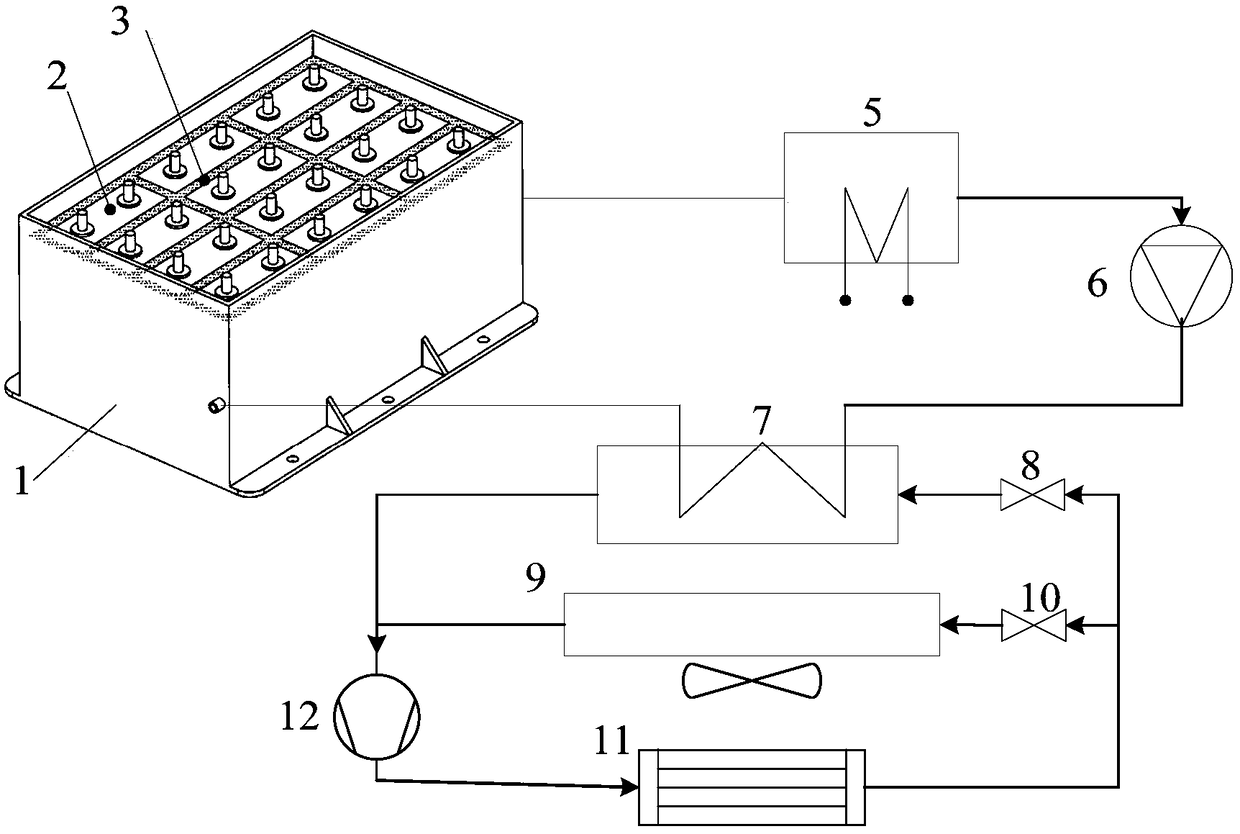

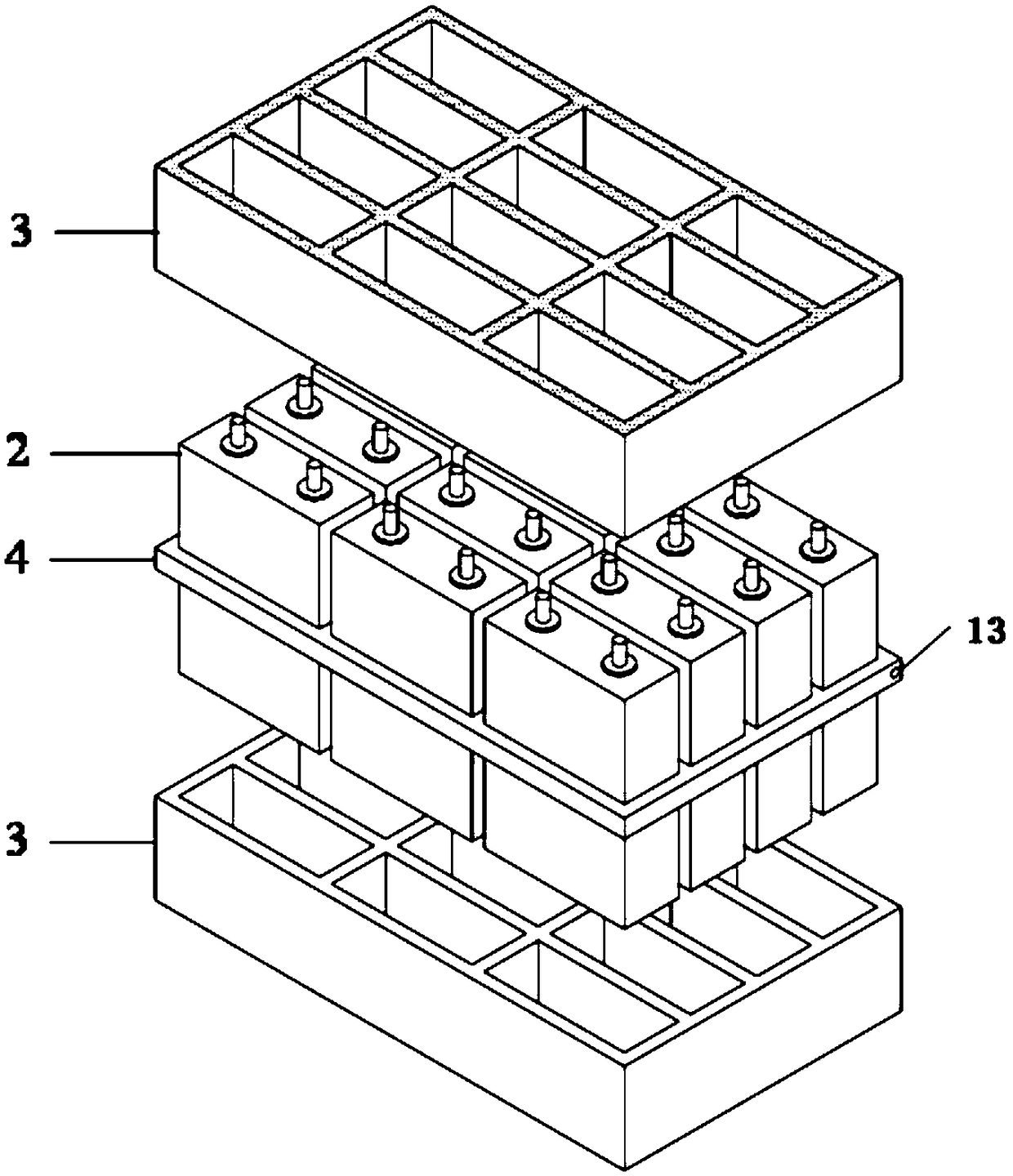

[0034] Such as Figure 1-Figure 4 As shown, a battery thermal management system has the functions of high-efficiency heat dissipation, heat preservation and heating, including the battery box and external circulation equipment.

[0035] The battery box 1 includes a battery box body 2, and a battery module is arranged in the battery box. The battery module is composed of N×M battery cells, and the battery cells are connected in series and parallel according to the actual situation to form a battery module. Composite phase-change material 3 is filled between the battery cells, and the composite phase-change material can be directly pressed and molded by a mold to be directly placed on each battery cell, or pressed into a block material and then machined to the required size. The composite phase change material is composed of paraffin wax / high molecular polymer / flame retardant / expanded graphite, and its phase change temperature is between 38-45 degrees.

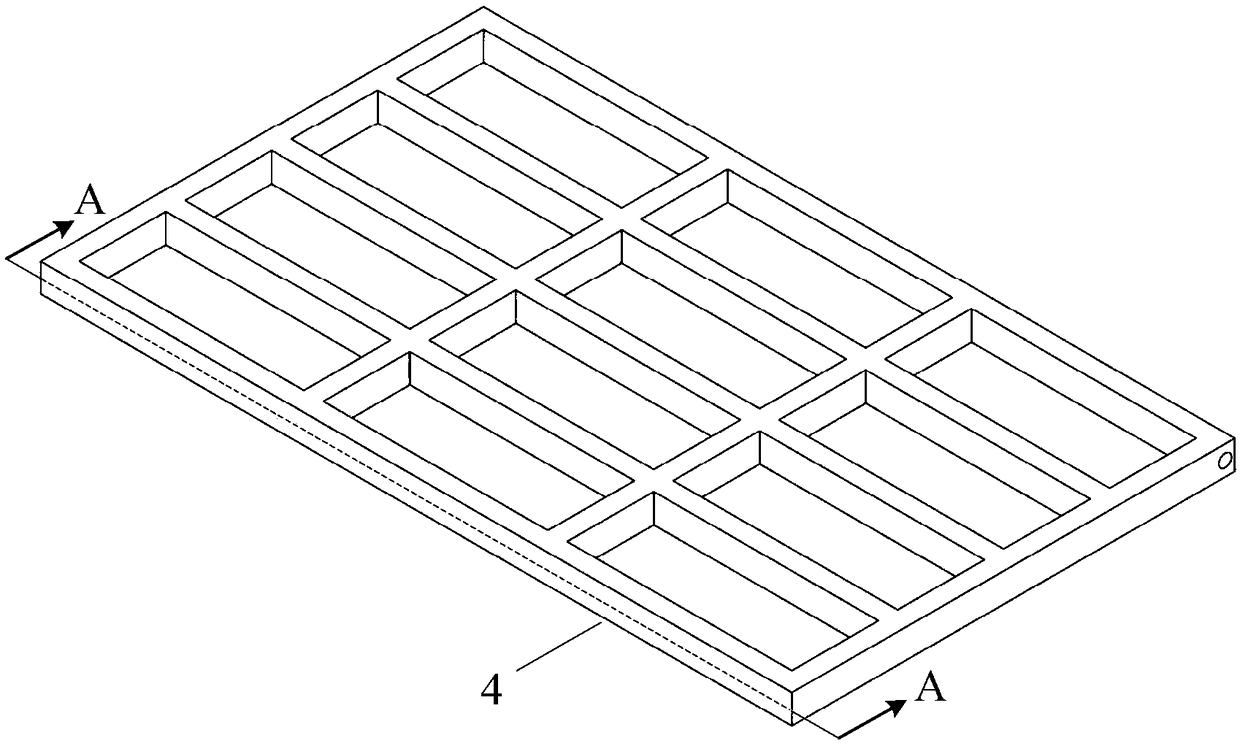

[0036] A cold plate 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com