Polyhydroxyamide composition and polybenzoxazole resin film for use in manufacturing substrates for electronic devices

A polyhydroxyamide and polybenzoxazole technology, applied in circuit substrate materials, printed circuit components, etc., can solve the problems of poor heat resistance, high toxicity, and high price of silanizing agents, and achieve high heat resistance, line The effect of a small expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

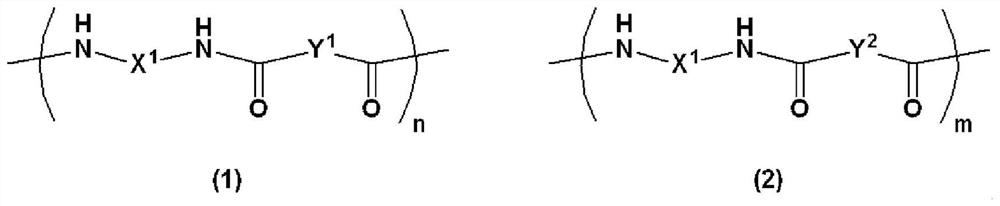

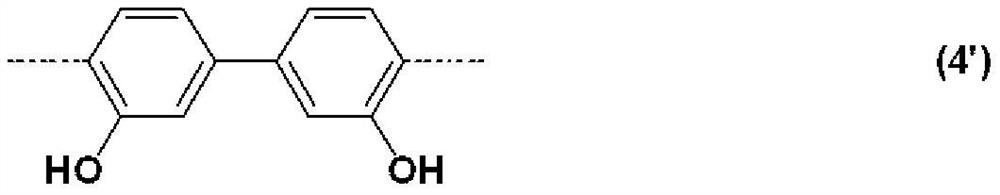

[0188] [Example 1] Synthesis of polyhydroxyamide P1

[0189] After dissolving HAB1.052g (4.87mmol) in NMP27.6g and adding pyridine 0.963g (12.18mmol), DEDC1.149g (3.90mmol) and TPC0.198g (0.97mmol) were added, and it stirred at room temperature for 24 hours. Then, the obtained solution was poured into 500 mL of pure water. The obtained precipitate was separated by filtration, and then dried under reduced pressure at 70° C. for 24 hours to obtain the target polyhydroxyamide P1. The Mw of the obtained polyhydroxyamide P1 measured by GPC was 60,300, and the Mw / Mn was 2.8.

Embodiment 2、 comparative example 1~5

[0190] [Example 2, Comparative Examples 1-5] Synthesis of Polyhydroxyamide P2, Polyhydroxyamide CP1-CP5

[0191] Polyhydroxyamide P2 and polyhydroxyamides CP1 to CP5 were synthesized in the same manner as in Example 1. Table 1 shows the type and amount of dicarboxylic acid chloride used, the type and amount of diamine used, the amount of NMP used, Mw, and Mw / Mn.

[0192] [2] Evaluation of the solubility of polyhydroxyamide

[0193] 1 g of the prepared polyhydroxyamide was put into 20 g of NMP, and stirred at room temperature for 48 hours to redissolve it.

[0194] The results are shown in Table 1 together. In addition, the evaluation criteria of solubility are as follows.

[0195] ◯: Dissolved during polymerization and redissolved after purification.

[0196] Δ: Dissolved during polymerization, but not redissolved after purification.

[0197] ×: Precipitated during polymerization.

[0198] [Table 1]

[0199]

[0200] [2] Production and evaluation of polybenzoxazole r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com