Fin material for heat exchanger, and heat exchanger

A technology of heat exchangers and fins, which is applied in the field of heat exchangers, can solve problems such as fin material cracks and large mold wear, and achieve the effects of preventing the reduction of formability and excellent hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

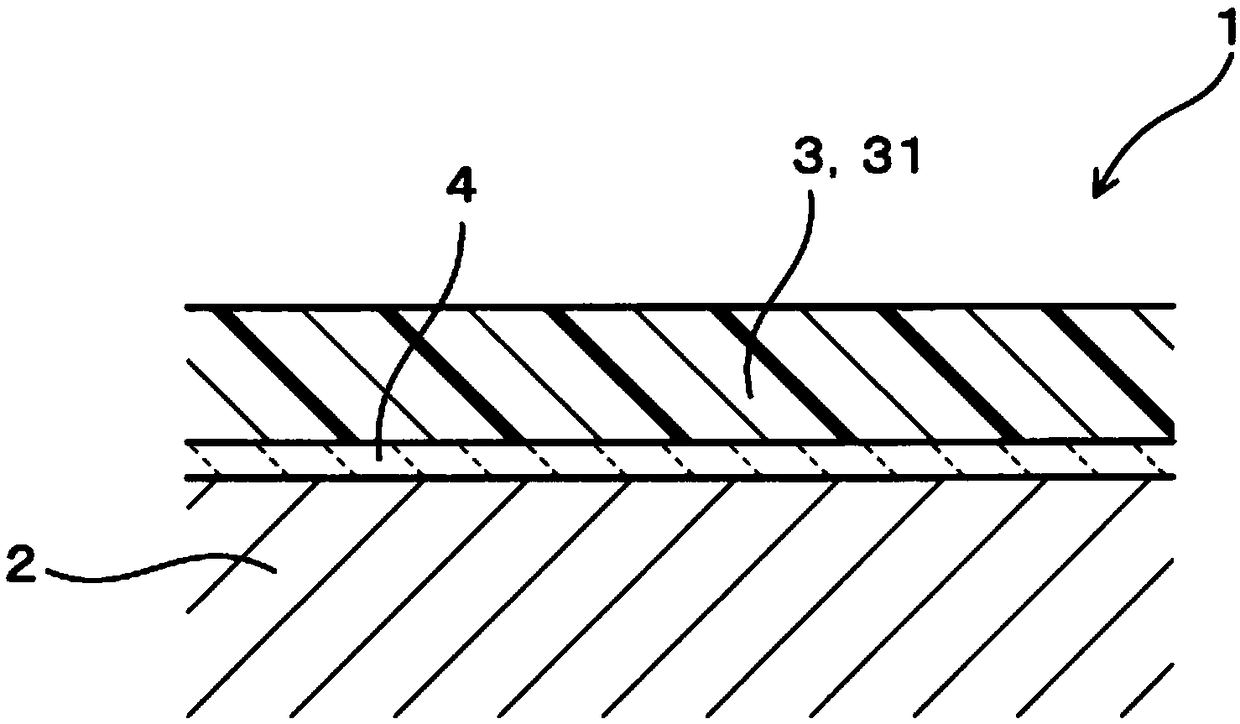

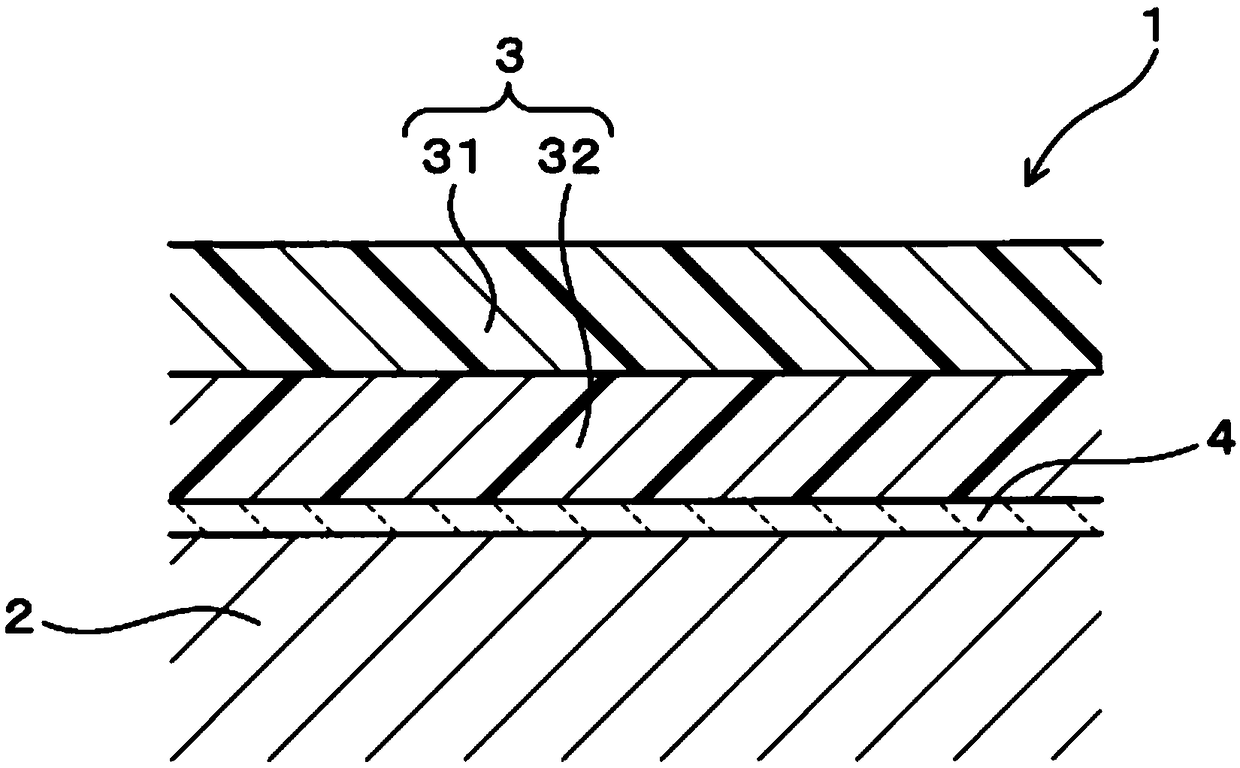

[0061] This example is an example in which fin materials (sample E1 to sample E20) according to examples of the present invention and fin materials (sample R1 to sample R11) according to comparative examples were prepared and these characteristics were evaluated. Such as figure 1 As shown, the fin materials 1 of samples E1 to E20 have a substrate 2 made of aluminum and a coating film 3 formed on the surface thereof. The coating film 3 is composed of a hydrophilic colored film 31 . A chemically synthesized film 4 is formed between the substrate 2 and the coating film 3 . The lamination structure of the film of sample R1 - sample R11 is the same as that of sample E1 - sample E20. Each of the samples E1 to E20, and the samples R1 to R11 differed in the constituent components of the hydrophilic colored film 31 as shown in Table 1 to be described later. The amount of each component in Table 1 is the amount of solid content.

[0062] Hereinafter, the manufacturing method of a fi...

Embodiment 2

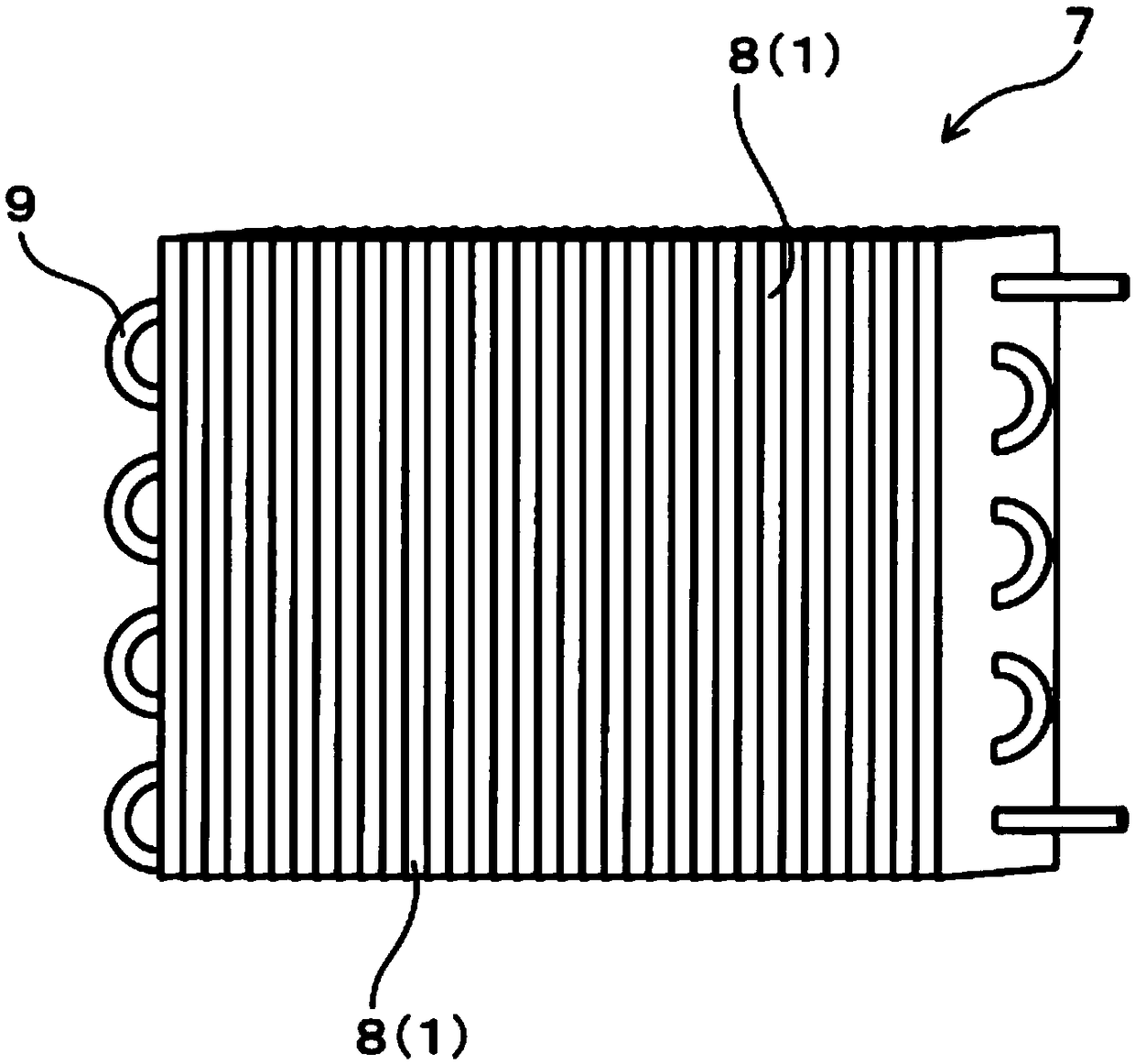

[0101] This example is an example of a heat exchanger including fins made of the fin material of Example 1. Such as image 3 As illustrated, the heat exchanger 7 is a cross-fin tube type, and has a plurality of plate-shaped fins 8 made of a fin material 1 , and a metal tube 9 for heat conduction passing through these fins. The fins 8 are arranged in parallel with predetermined intervals therebetween. The width of the fins 8 is, for example, 25.4 mm, the height is, for example, 290 mm, the stacking pitch of the fins 8 is, for example, 1.4 mm, and the overall width of the heat exchanger 1 is, for example, 300 mm. The height direction of the fins 8 is parallel to the rolling direction of the substrate. The metal tubes 9 in the width direction of the fins 8 are two rows, and the number of metal tubes 9 in the height direction of the fins 8 is 14. In addition, in image 3 Among them, for the convenience of making drawings, the number of metal pipes 9 is omitted. In addition, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com