Industrial waste gas, wastewater and circular cooling water physical and chemical treatment system

A technology for circulating cooling water and industrial waste gas, which is applied in water/sewage treatment, light water/sewage treatment, oxidized water/sewage treatment, etc. It can solve the problems of secondary pollution and the inability to simultaneously recycle waste gas and waste water. Achieve the effects of reducing wastewater discharge, saving costs and water consumption, and ultra-low corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

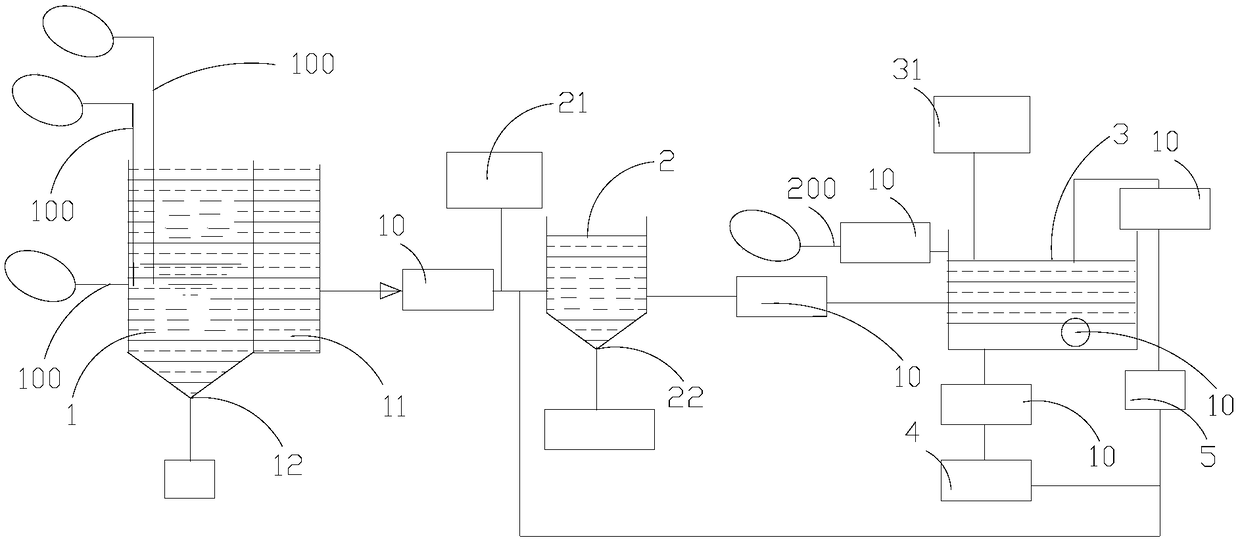

[0023] Embodiment 1 provides a physical and chemical treatment system for industrial waste gas, waste water, and circulating cooling water, including: a mixing pool 1, a filtering device 2, a circulating pool 3, a heat exchanger 4, and pipes for industrial water sources, waste gas, and waste water connected to the mixing pool 1. The mixing pool 1 is connected to the front end of the filter equipment 2 through pipelines, the water outlet of the filter equipment 2 is connected to the water inlet end of the circulation pool 3, and the water outlet end of the circulation pool 3 is connected to the front end of the heat exchanger 4, and the heat exchanger 4 After passing through the return pipe, the first water outlet end is circularly connected to the circulating water pool 3, and the second water outlet end is connected to the front end of the filter device 2, wherein a water processor is provided in the circulating water pool 3 and / or at the inlet and outlet ends of the circulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com