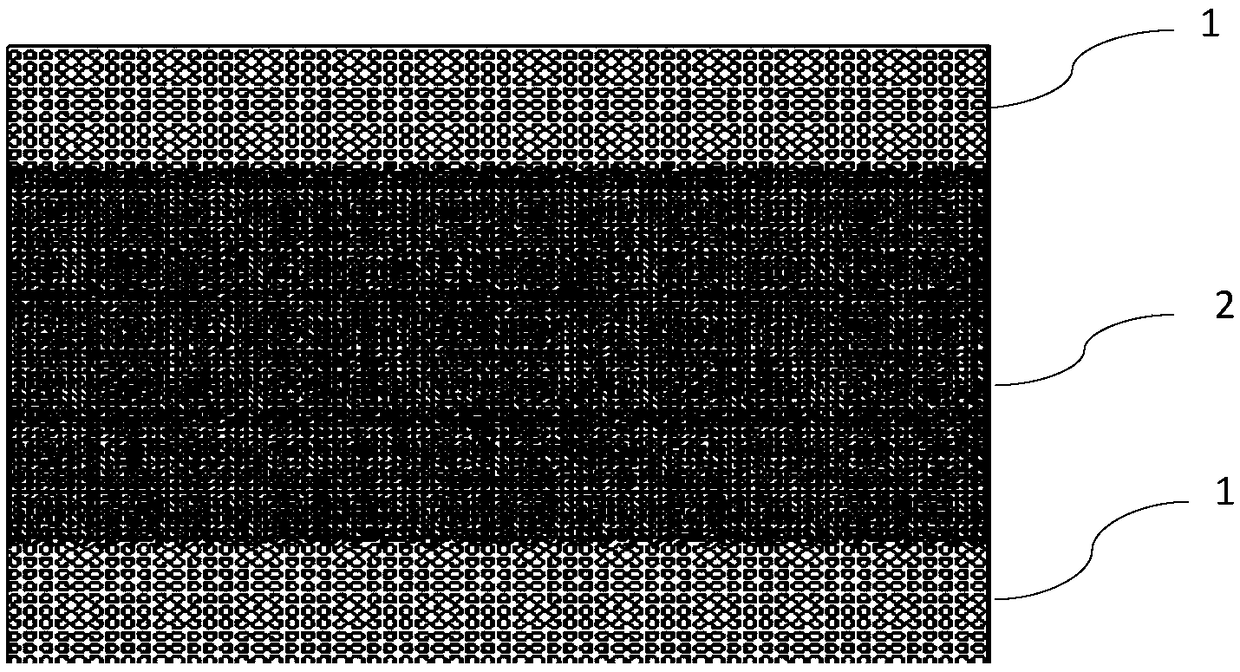

Ultra-thin high-strength compound man-made art slabstone and preparation method thereof

A man-made, high-strength technology, applied in the field of building materials, can solve the problems of heavy and low strength of artificial art stone, and achieve the effect of high strength and simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of the above-mentioned ultra-thin high-strength composite artificial art stone slab comprises the following steps:

[0046] A, the surface layer quartz sand particles in the surface layer, surface layer quartz sand powder, talcum powder, curing agent, accelerator, multifunctional epoxy resin, isocyanic acid modified epoxy resin, phosphorus-containing epoxy resin, phenolic oxygen resin, The coupling agent, the pigment and the first solvent are uniformly mixed with each other to obtain the surface layer mixture, which is set aside; the aluminum hydroxide in the substrate layer, the quartz sand powder of the substrate layer, the curing agent, the accelerator, the multifunctional epoxy resin, and the isocyanate Cyanic acid modified epoxy resin, phenolic resin, base material layer coupling agent and the second solvent are evenly mixed with each other to obtain the base material layer mixture for subsequent use; wherein, the mass ratio of each raw materi...

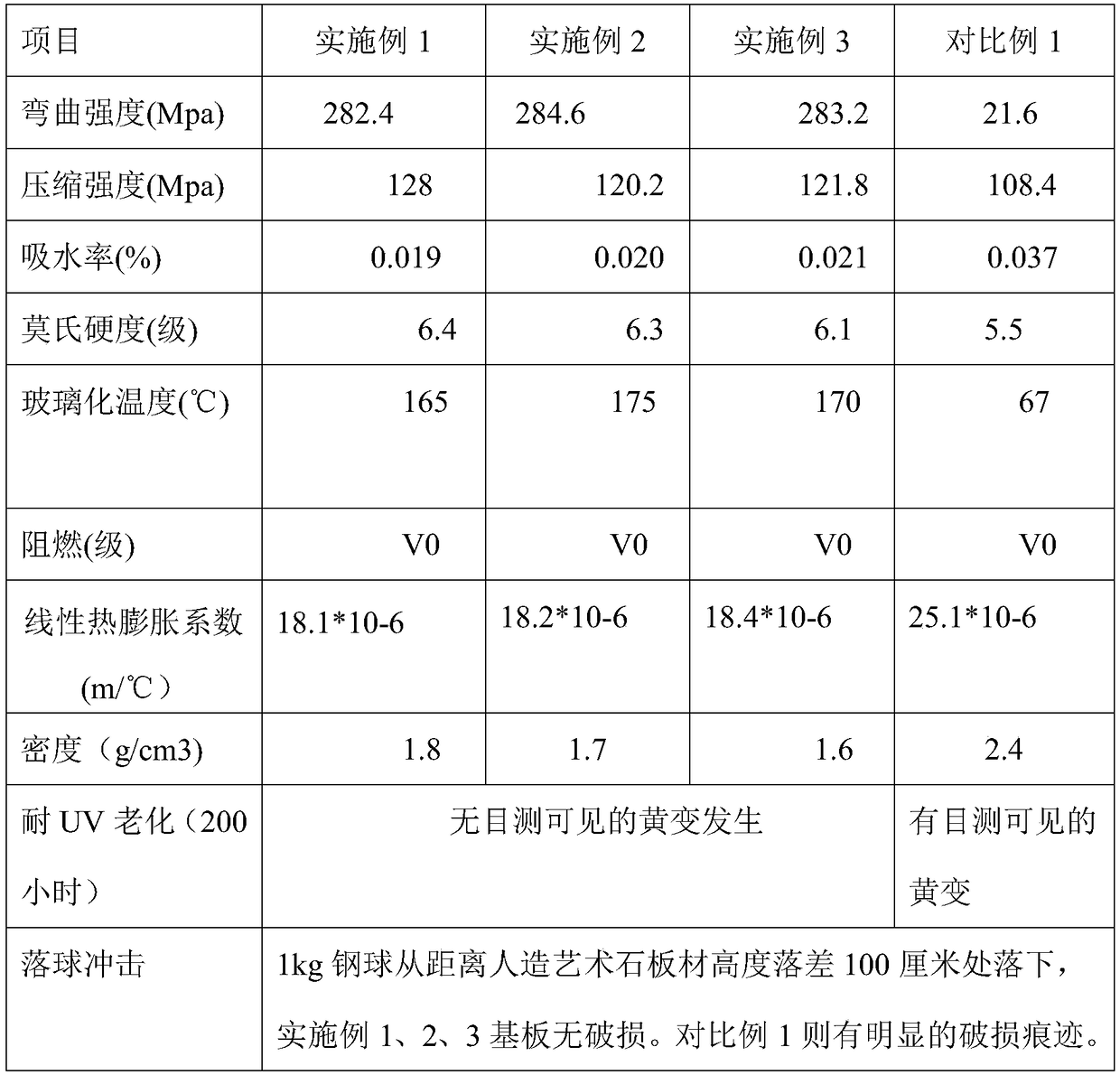

Embodiment 1

[0067] Prepare the surface layer mixture (× 1kg) of the artificial art stone slab according to the following mass parts ratio: 60 parts of surface layer quartz sand particles, 5 parts of surface layer quartz sand powder, 3 parts of talcum powder, 0.2 part of curing agent, 0.05 part of accelerator, more 3 parts of functional epoxy resin, 2 parts of isocyanic acid modified epoxy resin, 2 parts of phosphorus-containing epoxy resin, 0.5 part of phenolic resin, 0.02 part of coupling agent, 0.3 part of pigment, 3 parts of first solvent and aramid Fiber mesh cloth 2 parts. Among them, the particle size of the surface quartz sand is a mixture of 40-120 mesh continuous gradation, the particle size of the surface quartz sand powder is 200 mesh, the particle size range of talcum powder is: 1000-3000 mesh, and the curing agent in the surface layer is dicyandiamide , the accelerator in the surface layer is 2-methylimidazole, the multifunctional epoxy resin in the surface layer is a phenol-...

Embodiment 3

[0075] Prepare the surface layer mixture (× 1kg) of the artificial art stone slab according to the following mass parts ratio: 75 parts of surface layer quartz sand particles, 22.5 parts of surface layer quartz sand powder, 4 parts of talcum powder, 2.1 parts of curing agent, 0.28 parts of accelerator, more 5 parts of functional epoxy resin, 3 parts of isocyanic acid modified epoxy resin, 3 parts of phosphorus-containing epoxy resin, 1.2 parts of phenolic resin, 0.035 parts of coupling agent, 0.6 parts of pigment, 4 parts of first solvent and aramid Fiber mesh cloth 3.5 parts. Wherein, the particle size of the quartz sand particles in the surface layer is a continuous gradation mixture of 60 mesh-120 mesh, the particle size of the quartz sand powder in the surface layer is 400 mesh, the particle size of the talcum powder is: 1000-3000 mesh, and the curing agent in the surface layer is novolac ( Shandong Shengquan Chemical Industry, SH-1066), the accelerator in the surface laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com