Preparation method of inp-based alloy quantum dot, quantum dot, device and composition

A technology of quantum dots and base alloys, applied in the field of quantum dots, can solve problems such as low quantum efficiency, wide half-width of quantum dots, and weak stability, and achieve high quantum efficiency, improved size uniformity, and strong stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

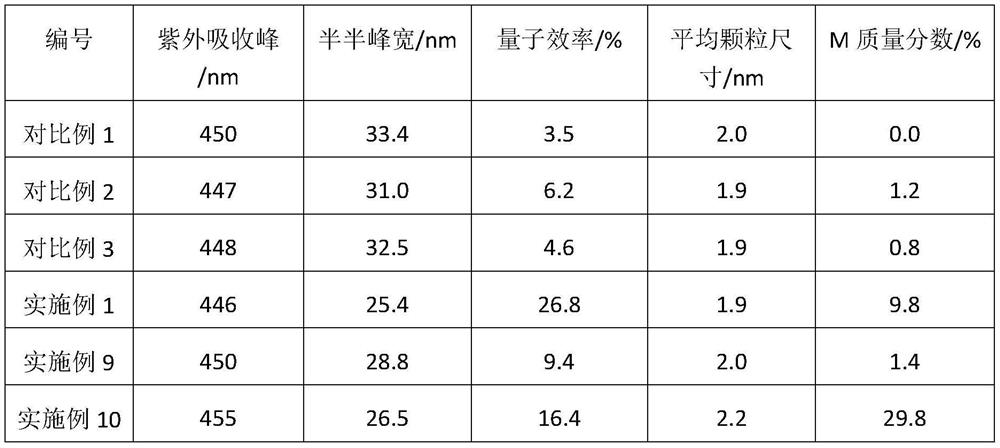

[0031] As introduced in the background art, InP quantum dots synthesized from InP-based alloy quantum dots in the prior art have wide half-maximum width, low luminous efficiency, poor coating effect and weak stability. The inventor of the present application studies the above-mentioned problems, and proposes a method for preparing InP-based alloy quantum dots. The method for preparing InP-based alloy quantum dots includes the following steps, 1) combining M precursors with phosphorus precursors, which can be The mixture of the selected first ligand and the first solvent is reacted at the first temperature to form the M-P complex solution; 2) the M-P complex solution is mixed with the indium precursor, the optional second ligand, and the second solvent React at the second temperature to obtain a solution containing InMP alloy quantum dots. Wherein, the InMP alloy quantum dots are InP-based alloy quantum dots. In the synthesis process of the InP-based alloy quantum dots, the M-...

Embodiment 1

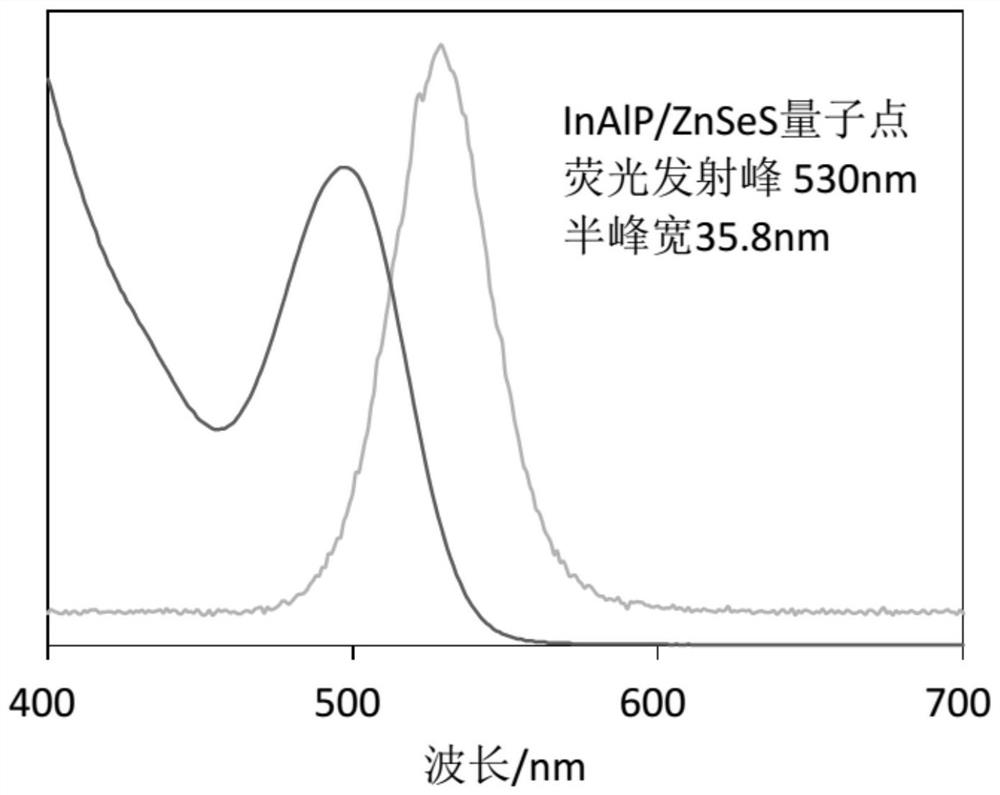

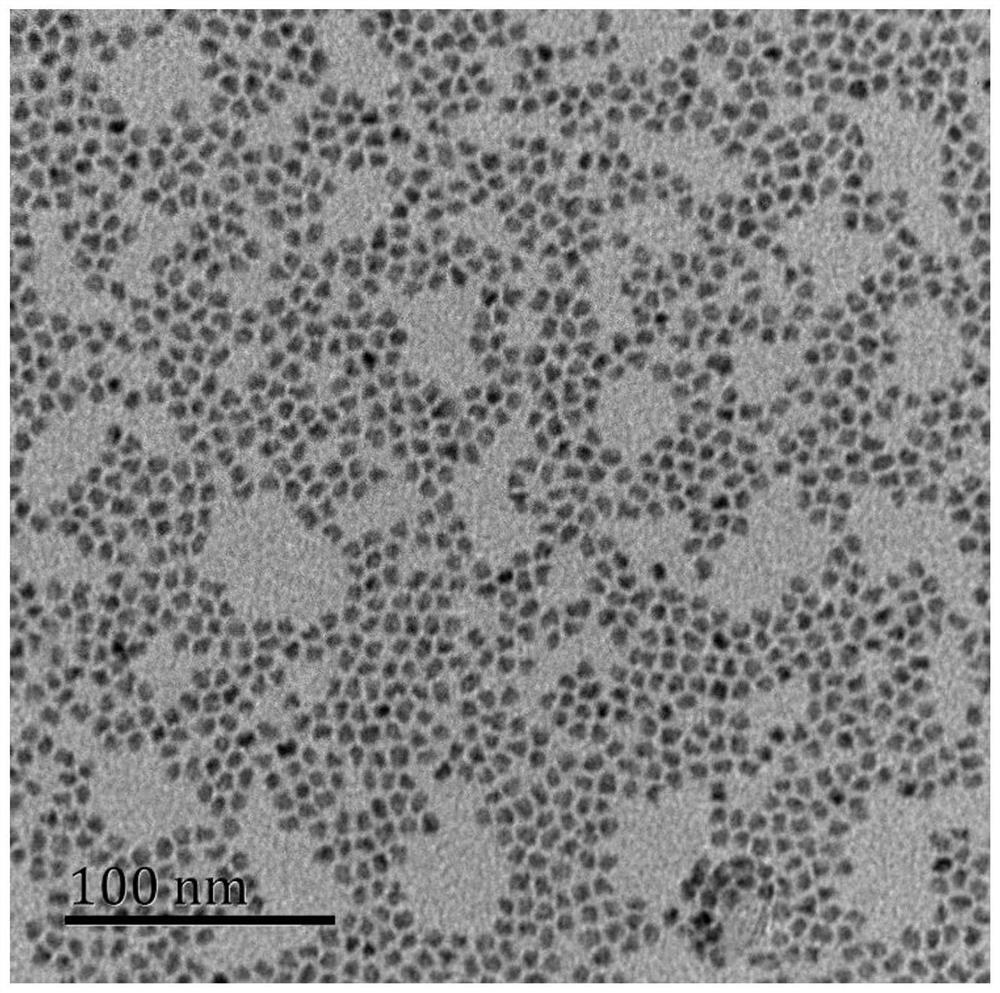

[0047] The preparation method of InP-based alloy quantum dots provided in this embodiment takes InAlP / ZnSeS quantum dots as an example, and the preparation method includes the following steps:

[0048] 1) Add 0.1mmol Al(MA) 3 (Aluminum myristate) and 0.1mmol TMS-P (three (trimethylsilyl) phosphine), the mixture of 0.1mmol trioctylamine, 3.0g octadecene joins in the 25mL three-necked flask, and this three-necked flask is placed in N 2 Heated to 80°C under the exhaust state, reacted at the reaction temperature of 80°C, kept for 30 minutes and then lowered to room temperature to form an Al-P composite solution;

[0049] 2) Add 0.3mmol In(Ac) 3 (indium acetate), 0.9mmol myristic acid, the mixture of 10.0g octadecene joins in the 100mL three-necked flask, under N 2 Heated to 180°C under the exhaust state, kept it for 30 minutes and then lowered to 300°C. Inject the Al-P composite solution obtained in step 1), react at a reaction temperature of 300° C., and keep for 5 minutes to...

Embodiment 2

[0052] The difference between this example and Example 1 is that zirconium myristate is used instead of aluminum myristate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com