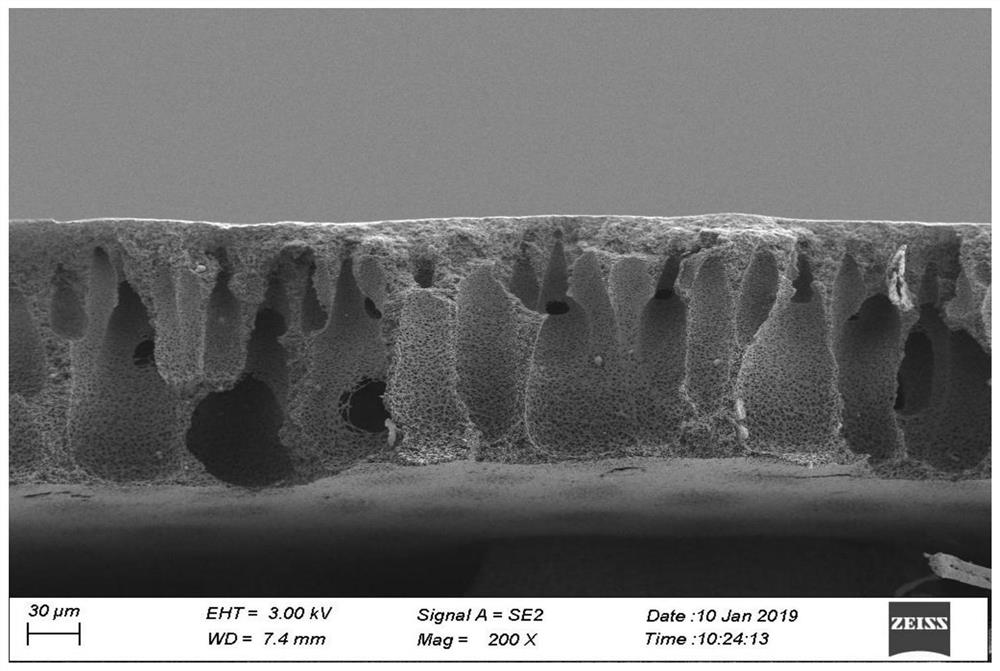

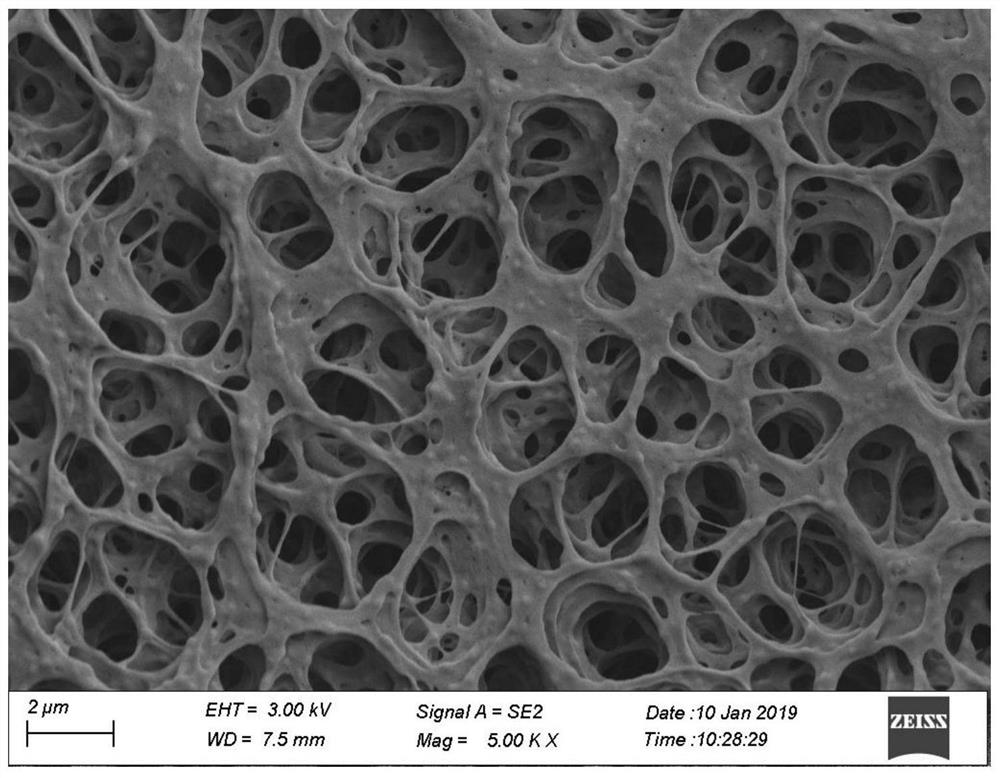

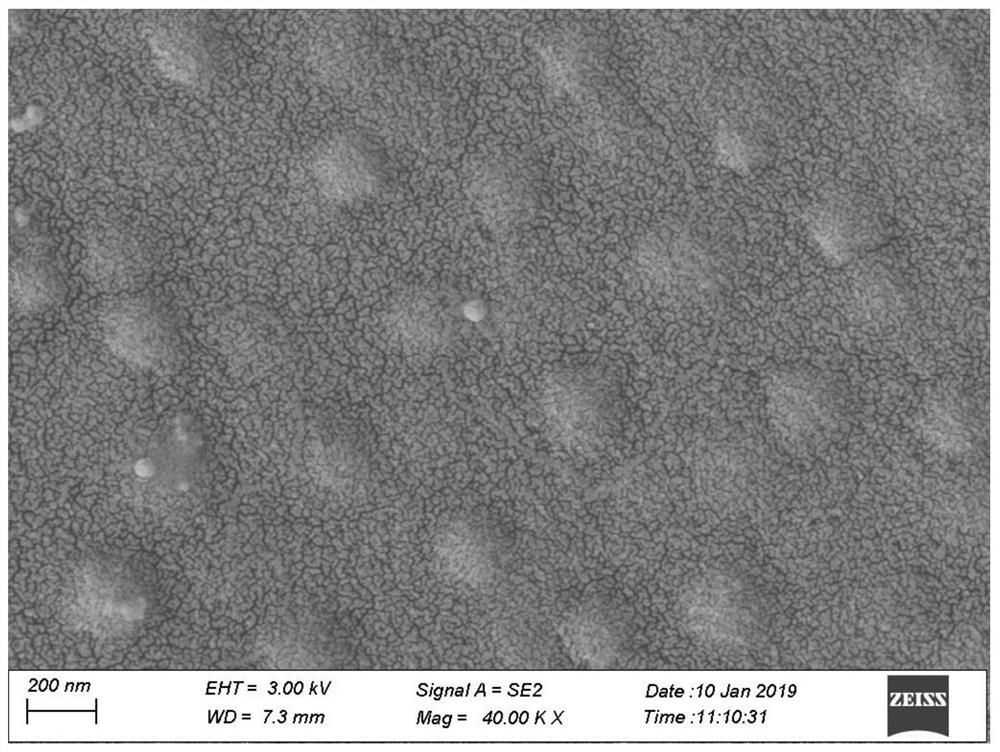

A gradient functional organic-inorganic hybrid membrane for advanced water treatment and its preparation method

A gradient function and advanced treatment technology, applied in the field of membrane materials, can solve the problems of severe aggregation of nanoparticles and damage to the mechanical properties of the membrane, and achieve the effects of improving water flux, increasing interaction, and improving size uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A gradient functional organic-inorganic hybrid membrane for advanced water treatment and a preparation method thereof, comprising the following steps:

[0030] S1. Preparation of casting solution: ultrasonically disperse the magnetic nanoparticles modified by interfacial polymerization in N-methylpyrrolidone, then add polyethylene glycol (400), polyethylene glycol (20000) and polyvinylidene fluoride to fully Mixing, stirring, heating, static defoaming to obtain a uniform casting solution;

[0031] The casting solution is made of the following raw materials according to mass percentage: 75% of N-methylpyrrolidone, 0.01% of magnetic nanoparticles modified by interfacial polymerization, 6% of polyethylene glycol (400), polyethylene glycol (20000) 4% and PVDF 14.99%.

[0032] The interfacial polymerization modified magnetic nanoparticles are polyamide interfacial polymerization modified magnetic sepiolite, magnetic halloysite and magnetic graphene oxide with a mass ratio o...

Embodiment 2

[0046] A gradient functional organic-inorganic hybrid membrane for water advanced treatment, and its preparation method comprises the following steps:

[0047] S1.. Preparation of casting solution: ultrasonically disperse interfacial polymerization modified magnetic nanoparticles in N-methylpyrrolidone, then add polyethylene glycol (400), polyethylene glycol (20000) and polyvinylidene fluoride Thoroughly mix, stir, heat, and stand still to defoam to obtain a uniform casting solution;

[0048] The casting solution is made of the following raw materials according to mass percentage: 75% of N-methylpyrrolidone, 0.5% of magnetic nanoparticles modified by interfacial polymerization, 6% of polyethylene glycol (400), polyethylene glycol (20000) 4% and PVDF 14.5%.

[0049] The interfacial polymerization modified magnetic nanoparticles are polyamide interfacial polymerization modified magnetic sepiolite, magnetic halloysite and magnetic graphene oxide with a mass ratio of 6:4:4.

[0...

Embodiment 3

[0052] A gradient functional organic-inorganic hybrid membrane for water advanced treatment, and its preparation method comprises the following steps:

[0053] S1.. Preparation of casting solution: ultrasonically disperse interfacial polymerization modified magnetic nanoparticles in N-methylpyrrolidone, then add polyethylene glycol (400), polyethylene glycol (20000) and polyvinylidene fluoride Thoroughly mix, stir, heat, and stand still to defoam to obtain a uniform casting solution;

[0054] The casting solution is made of the following raw materials according to mass percentage: 75% of N-methylpyrrolidone, 1% of magnetic nanoparticles modified by interfacial polymerization, 6% of polyethylene glycol (400), polyethylene glycol (20000) 4% and PVDF 14%.

[0055] The interfacial polymerization modified magnetic nanoparticles are polyamide interfacial polymerization modified magnetic sepiolite, magnetic halloysite and magnetic graphene oxide with a mass ratio of 6:4:4.

[0056]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com