A kind of manufacturing method of resin optical lens

The technology of an optical lens and a manufacturing method, which is applied in the field of lens manufacturing, can solve problems such as difficult control of surface precision, influence on lens optical performance, and inability to deal with lens layer patterns, so as to ensure performance and quality, shorten the production cycle, and improve the production method. flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

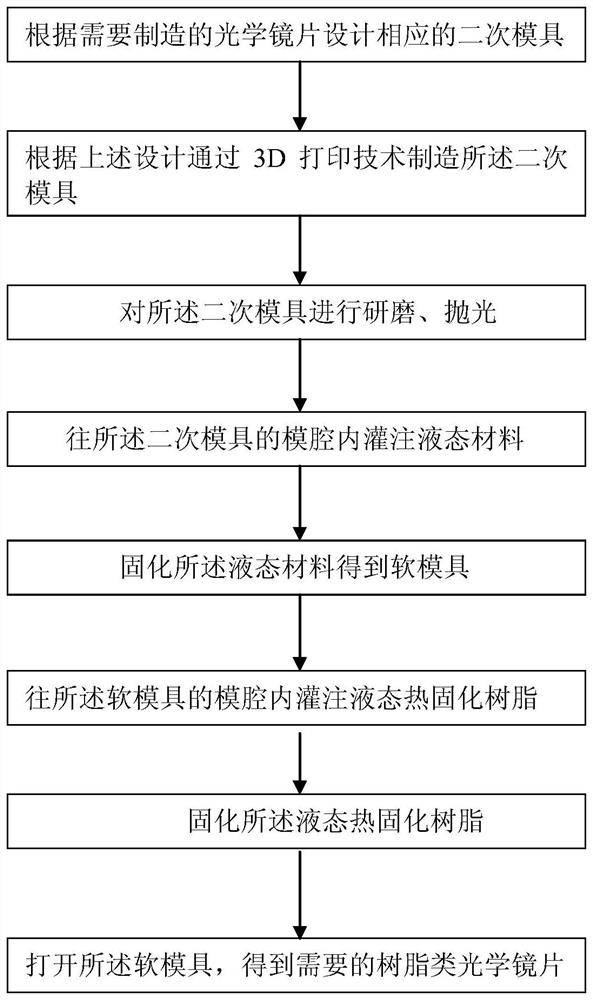

[0043] Such as figure 1 Shown, the manufacture method of resin optical lens of the present invention comprises the following steps:

[0044] The first step is to design the corresponding secondary mold according to the optical lens to be manufactured;

[0045] In the second step, according to the above design, the secondary mold is manufactured by 3D printing technology;

[0046] The third step, grinding and polishing the secondary mold;

[0047] The fourth step, pouring liquid material into the mold cavity of the secondary mold;

[0048] The fifth step, solidifying the liquid material to obtain a soft mold;

[0049] The sixth step, pouring liquid thermosetting resin into the mold cavity of the soft mold;

[0050] The seventh step, curing the liquid thermosetting resin;

[0051] The eighth step is to open the soft mold to obtain the required resin optical lens.

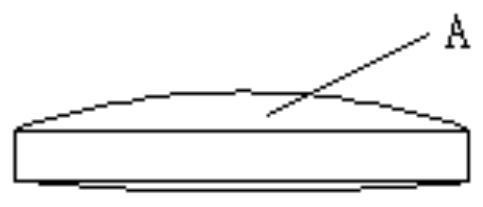

[0052] to make as figure 2 The shown resin optical lens A is an example to specifically describe the invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com