High-temperature activation purifying method for quartz sand

A technology of high-temperature activation and purification method, applied in the direction of silicon oxide, silicon dioxide, etc., can solve the problems of insufficient reaction of quartz sand, environmental and personal harm, large chlorinating agent, etc., to improve product quality, reduce dosage, reaction Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

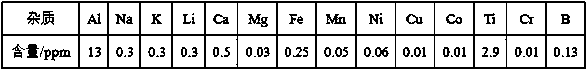

[0032] Firstly, the coarse quartz sand with a total impurity content of less than 50ppm, a particle size distribution of 100-240 mesh, and a median diameter of 130-170 mesh is screened as the raw material for activation and purification. The impurity content of the coarse quartz sand used in this example was detected by the ICP-OES method, and the detection data are shown in Table 1.

[0033] Table 1 Detection data of impurity content in coarse quartz sand

[0034]

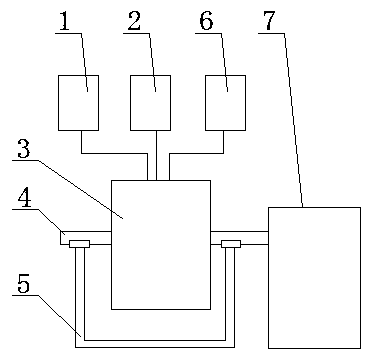

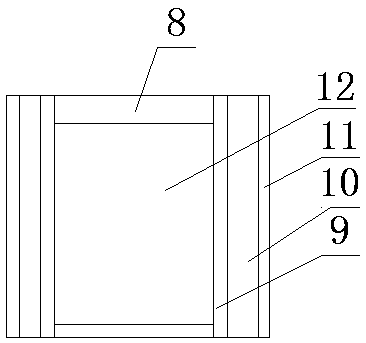

[0035] Use hydrofluoric acid solution or hydrofluoric acid, hydrochloric acid and sulfuric acid with a concentration of 0.05 mol / L to soak and pickle the hearth 12 and furnace cover 8 of the high-temperature activation furnace to ensure the cleanliness of the hearth 12 environment. The pickling time is 10 minutes. After pickling, use high-purity water to rinse the hearth 12 and furnace cover 8 of the high-temperature activation furnace 3 for more than 2 minutes. The high-temperature activation device is compos...

Embodiment 2

[0045] Firstly, the coarse quartz sand with a total impurity content of less than 50ppm, a particle size distribution of 120-220 mesh, and a median diameter of 140-160 mesh is screened as the raw material for activation and purification. The impurity content of the coarse quartz sand used in this example was detected by the ICP-OES method, and the detection data are shown in Table 3.

[0046] Table 3 Detection data of impurity content in coarse quartz sand

[0047]

[0048] Use hydrofluoric acid solution or hydrofluoric acid, hydrochloric acid and sulfuric acid with a concentration of 0.04 mol / L to soak and pickle the hearth 12 and furnace cover 8 of the high-temperature activation furnace to ensure the cleanliness of the hearth 12 environment. The pickling time is 8 minutes. After pickling, use high-purity water to rinse the hearth 12 and furnace cover 8 of the high-temperature activation furnace 3 for more than 2 minutes. The high-temperature activation device is compose...

Embodiment 3

[0058] Firstly, screen the coarse quartz sand with a total impurity content of less than 50ppm, a particle size distribution of 130-200 mesh, and a median diameter of 140-150 mesh as the raw material for activation and purification. The impurity content of quartz coarse sand was detected by ICP-OES method, and the detection results are shown in Table 5.

[0059] Table 5 Detection data of impurities in quartz coarse sand raw materials

[0060]

[0061] Use hydrofluoric acid solution or hydrofluoric acid, hydrochloric acid and sulfuric acid with a concentration of 0.03 mol / L to soak and pickle the hearth 12 and furnace cover 8 of the high-temperature activation furnace to ensure the cleanliness of the hearth 12 environment. The pickling time is 7 minutes. After pickling, use high-purity water to rinse the hearth 12 and furnace cover 8 of the high-temperature activation furnace 3 for more than 2 minutes. The high-temperature activation device is composed of a gas control devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com