Treatment method of dyestuff wastewater

A dye wastewater and treatment method technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem that wastewater is difficult to achieve better treatment effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

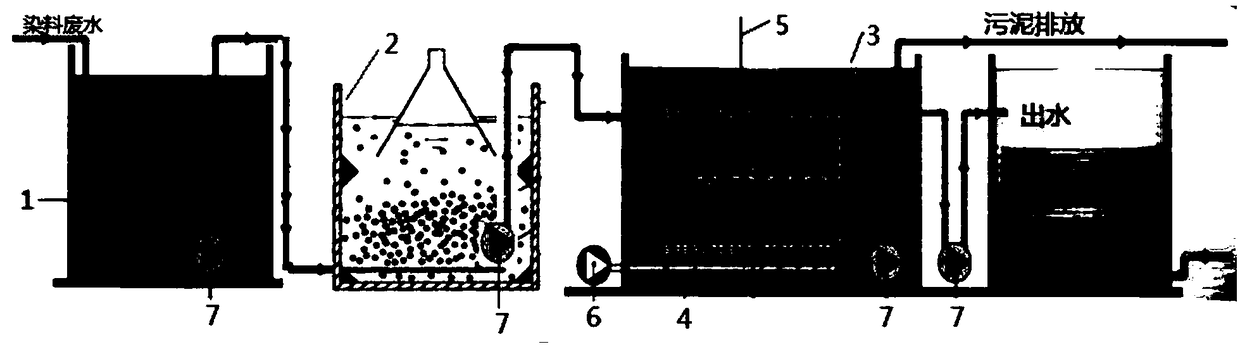

Image

Examples

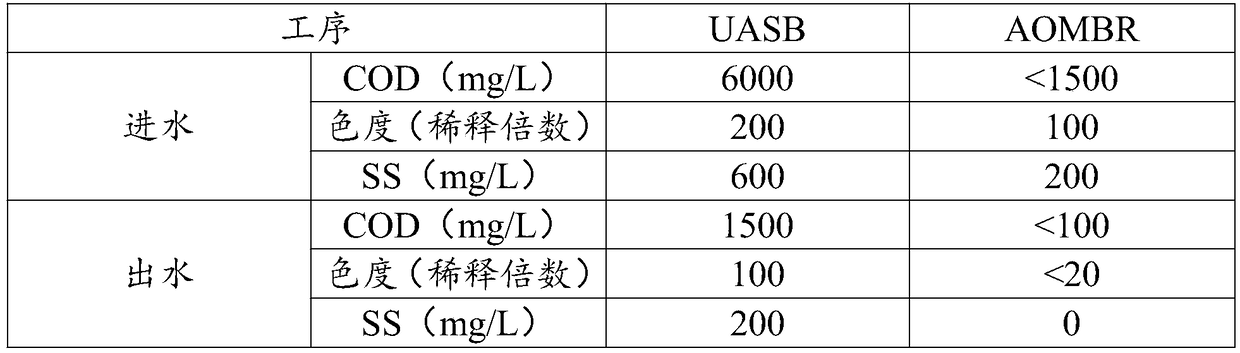

Embodiment 1

[0042] The initial content of COD in the dye wastewater is 6000mg / L, the initial chroma is 200 times, and the initial content of SS is 600mg / L;

[0043] The dye wastewater is first homogenized through the regulating tank, and the hydraulic retention time of the dye wastewater in the regulating tank is 12h;

[0044] The dye wastewater after the adjustment tank enters the anaerobic reactor (UASB) for anaerobic treatment. The hydraulic retention time in the anaerobic reactor is 10h, and the oxidation-reduction potential in the anaerobic treatment process is -230mV. The sludge concentration in the tank is 8g / L;

[0045] The dye wastewater after anaerobic treatment enters the anaerobic-aerobic integrated membrane bioreactor (hereinafter referred to as AOMBR) for anaerobic-aerobic cycle treatment. The membrane filaments filled in the reactor are hollow fiber membranes containing quinone groups. The sludge concentration in the AOMBR reactor is 6000m g / L; AOMBR operates according to ...

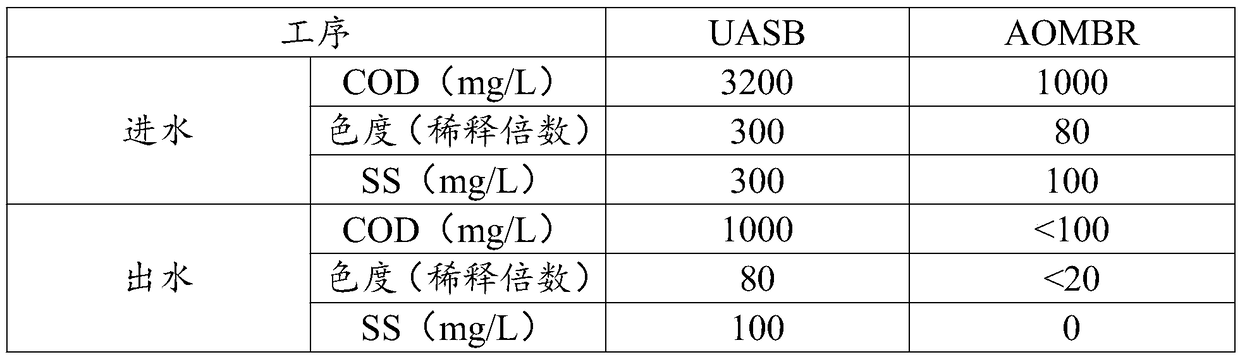

Embodiment 2

[0051] The initial content of COD in the dye wastewater is 3200mg / L, the initial chroma is 300 times, and the initial content of SS is 300mg / L;

[0052] The dye wastewater is first homogenized through the regulating tank, and the hydraulic retention time of the dye wastewater in the regulating tank is 12h;

[0053] The dye wastewater after the adjustment tank enters the anaerobic reactor (UASB) for anaerobic treatment. The hydraulic retention time in the anaerobic reactor is 12h, and the medium oxidation-reduction potential in the anaerobic treatment process is -200mV. The sludge concentration in the tank is 8g / L;

[0054] The dye wastewater after anaerobic treatment enters the anaerobic-aerobic integrated membrane bioreactor (hereinafter referred to as AOMBR) for anaerobic-aerobic cycle treatment. The membrane filaments filled in the reactor are hollow fiber membranes containing quinone groups, AOMBR The sludge concentration in the reactor is 7500mg / L; AOMBR operates accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com