Production process for improving the content of humic acid in organic fertilizer, and biological organic fertilizer

A bio-organic fertilizer and production process technology, which is applied in the preparation of organic fertilizers, the treatment of bio-organic parts, and organic fertilizers, can solve problems such as increasing production costs and failing to meet demand, and achieves improvements in soil, agricultural product quality, and rot. The effect of reproductive acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Effects of the preparation of the invention on cucumber growth, soil nutrients and rhizosphere microorganisms in continuous cropping greenhouses. The specific application method of bio-organic fertilizer during use is: as a base fertilizer, it is applied once before planting or planting. The cucumber variety for testing is Jinchun No. 4, and the commercially available bio-organic fertilizer is used as a contrast. The application rate of the present invention is 100 kg / mu, and the commercially available bio-organic fertilizer application rate is 120 kg / mu. During the experiment, all treatments did not use any fungicides and other base fertilizers.

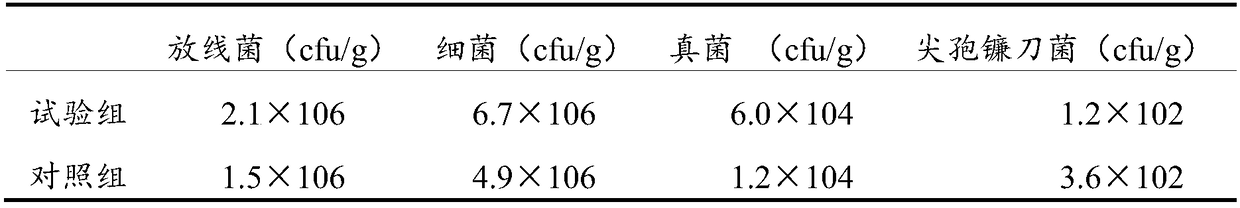

[0062] Table 1 The present invention is on the impact of continuous cropping cucumber rhizosphere soil microorganisms and pathogenic bacteria (after harvest)

[0063]

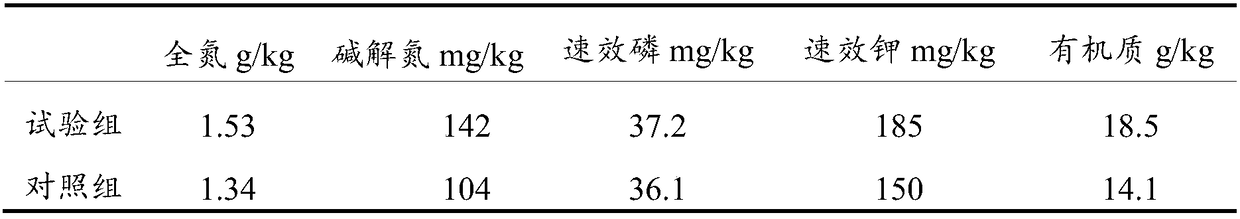

[0064] Table 2 The present invention is to the impact of continuous cropping cucumber greenhouse soil nutrient content (after the harvest)

[0065]

...

Embodiment 2

[0072] The influence of preparation of the present invention on strawberry yield and quality. The experimental variety is Fengxiang. The test group applied 100kg / mu of this product, and the control group applied commercially available bio-organic fertilizer 120kg / mu, and the protected land was cultivated conventionally.

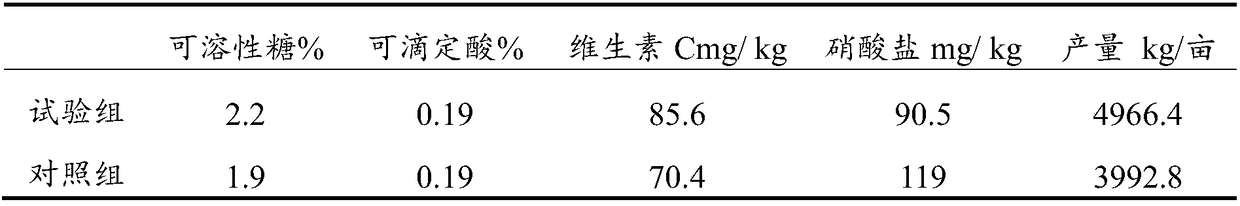

[0073] Table 5 The impact of this product on strawberry quality and yield

[0074]

[0075]

[0076] The results are shown in Table 5. Compared with the commercially available bio-organic fertilizer, the bio-organic fertilizer of the present invention can increase the sugar content of strawberries, improve the color, and increase the yield.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com