Polyfluorene derivative, light-emitting layer of light-emitting diode and preparation method thereof

A technology of light-emitting diodes and derivatives, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of unbalanced carrier transport, limited device efficiency and stability, and reduced hole transport performance. Achieve carrier transport balance, maintain color purity, and improve luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Preparation of Compound M1

[0037] (1) Preparation of Compound 1: Add dibenzothiophene (11g, 60mmol), iron powder (0.17g, 3mmol) and bromine (3.1mL, 60mmol) into a 100ml three-necked flask, and stir at room temperature under a nitrogen atmosphere for 16 After hours, the reaction was quenched with aqueous sodium bisulfite solution, followed by three extractions with dichloromethane, and the solvent was removed under reduced pressure to obtain a crude product, which was then purified by column with a yield of about 80%.

[0038] (2) Preparation of compound 2: Add compound 1 (3.3g, 12.5mmol) to a 100ml three-necked flask under nitrogen protection and dissolve it in dry tetrahydrofuran, then add butyllithium (3.3g, 12.5mmol), under nitrogen atmosphere , stirred at -78 degrees Celsius for 2 hours, then added 1-bromo-n-hexane (7.4g, 45mmol) to continue the reaction for 1 hour, then added water to quench the reaction, then extracted three times with dichloromethane, and remov...

Embodiment 1

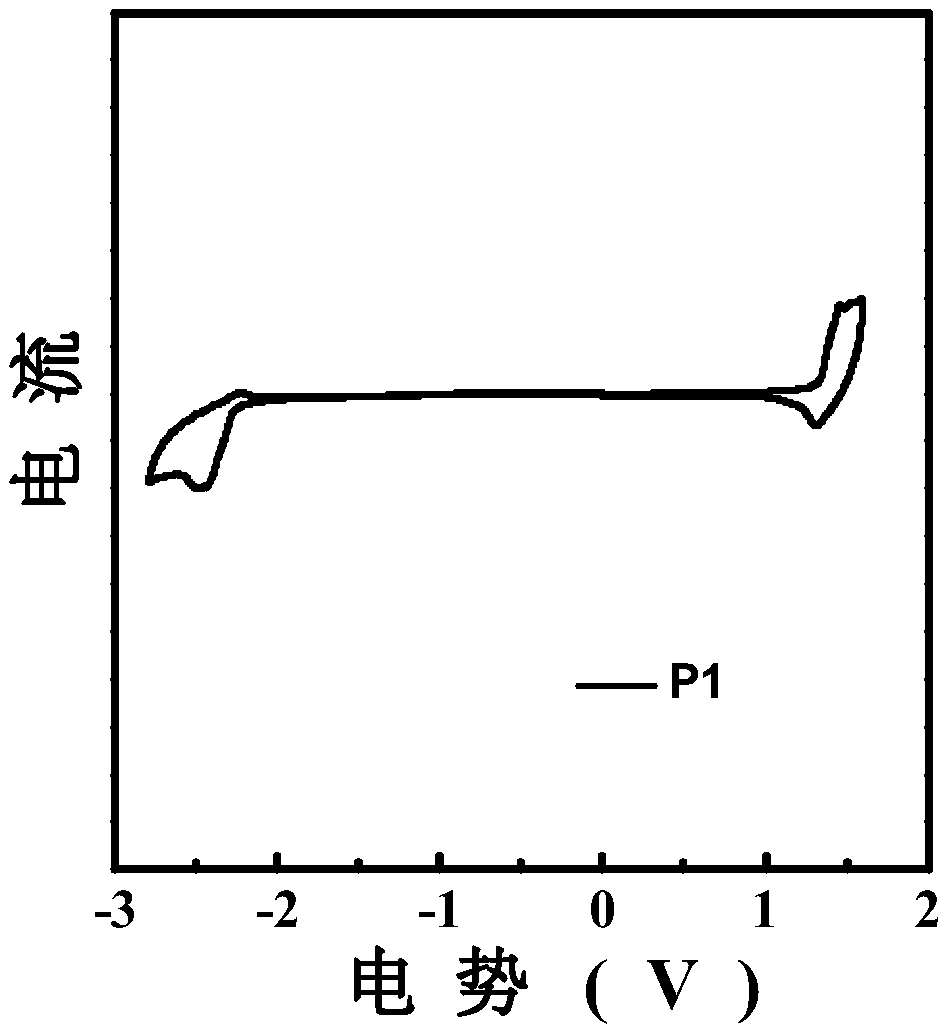

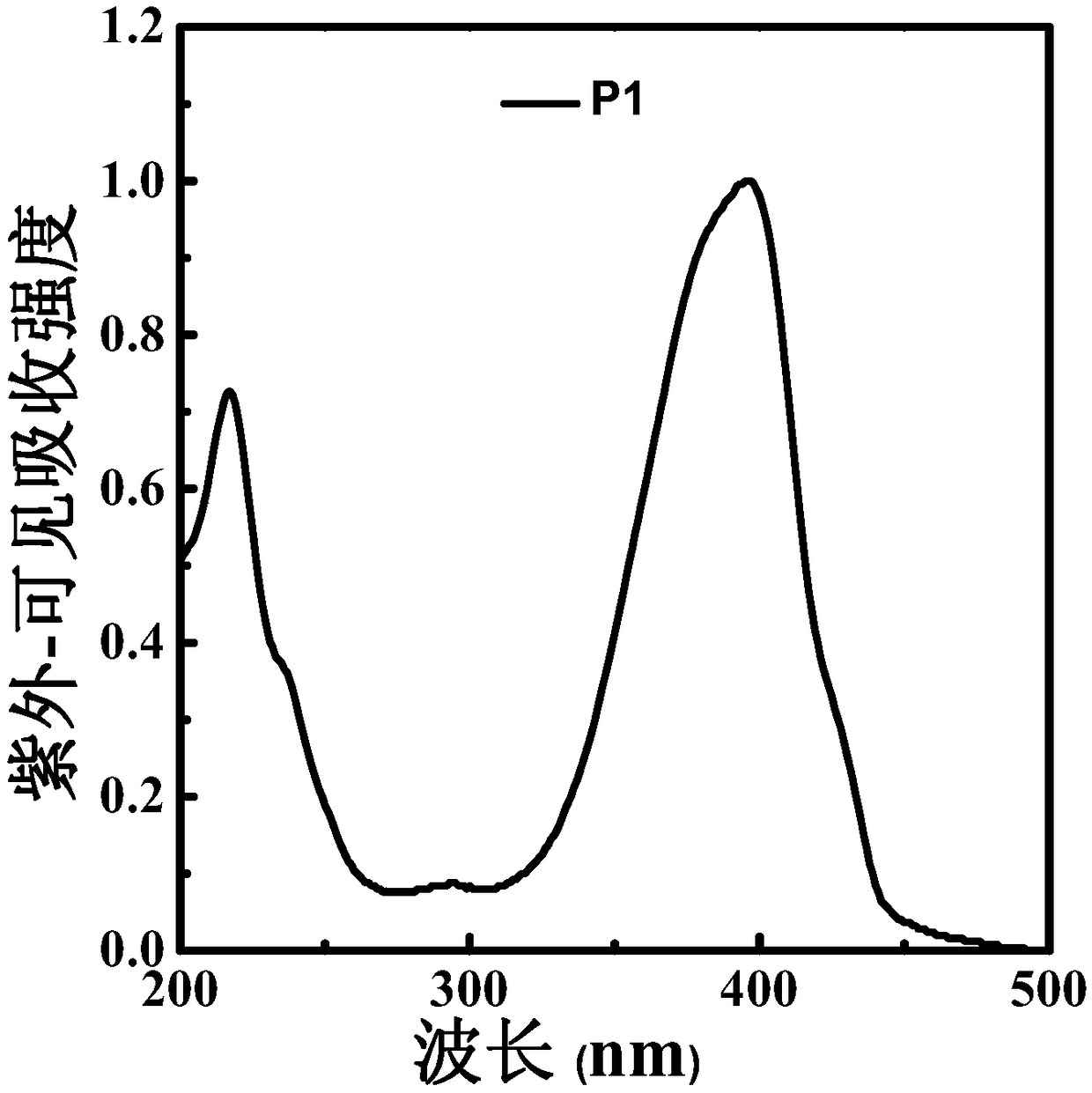

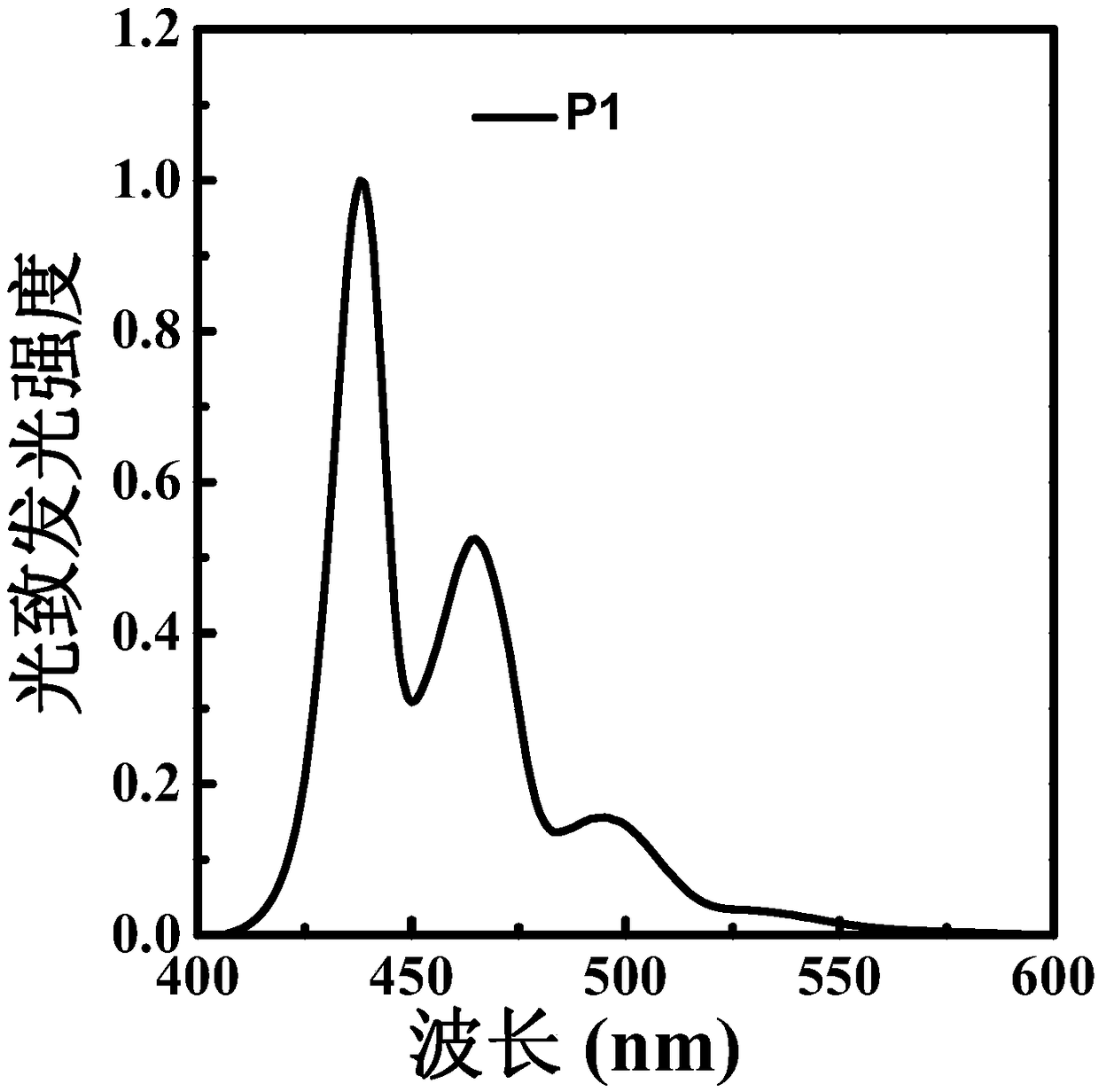

[0053] Preparation of Polymer P1

[0054] Synthesis of polymer P1: Under nitrogen protection, 2,7-bis(4,4,5,5-tetramethyl-1,3-dioxo-2-boryl)-9,9-bis(4 -(2-Ethylhexyloxy)phenyl)fluorene (248.0mg, 0.3mmol), 2,7-dibromo-9,9-bis(4-(2-ethylhexyloxy)phenyl ) fluorene (175.8mg, 0.24mmol), and compound M3 (48.6mg, 0.06mmol) were dissolved in 10mL of toluene, and then tetraethylhydroxylamine aqueous solution (1ml, wt% = 25%), palladium acetate (1mg) and three Cyclohexylphosphine (2mg); after heating to 80°C for 24 hours, add phenylboronic acid (20mg) to block for 6 hours, then add bromobenzene (0.2ml) to block at 80°C for 6 hours; the reaction stops, and after cooling, the organic Phase precipitation in methanol (200ml), filtered, and dried, the crude product was extracted successively with methanol, acetone, and n-hexane, and the polymer was dissolved with toluene, and toluene was used as eluent, and column chromatography was carried out with neutral alumina Purification; concentrat...

Embodiment 2

[0061] Preparation of Polymer P2

[0062] Polymer P2 was synthesized under the same conditions as Polymer P1, except that:

[0063] Polymer P2: 2,7-bis(4,4,5,5-tetramethyl-1,3-dioxo-2-boryl)-9,9-bis(4-(2-ethylhexyl Alkoxy)phenyl)fluorene (248.0mg, 0.3mmol), 2,7-dibromo-9,9-bis(4-(2-ethylhexyloxy)phenyl)fluorene (175.8mg, 0.24 mmol), and compound M1 (41.7mg, 0.06mmol). GPC: Mn=97KDa, PDI=3.21.

[0064]

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption wavelength | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com