High-opacity spraying-free PP material and preparation method thereof

A spray-free, high shading technology, applied in the field of spray-free materials, can solve the problem of inability to know the shading effect, achieve good dispersion and material shading, improve shading, and relieve flow marks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

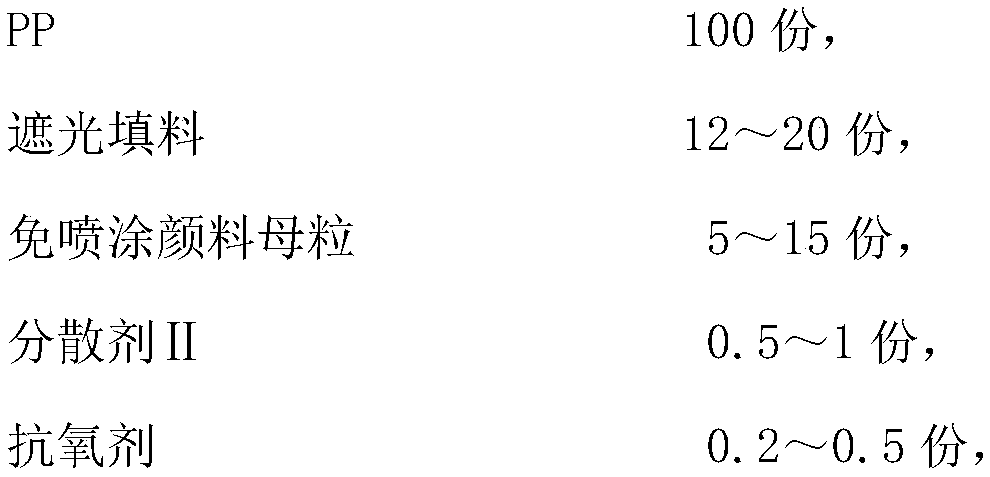

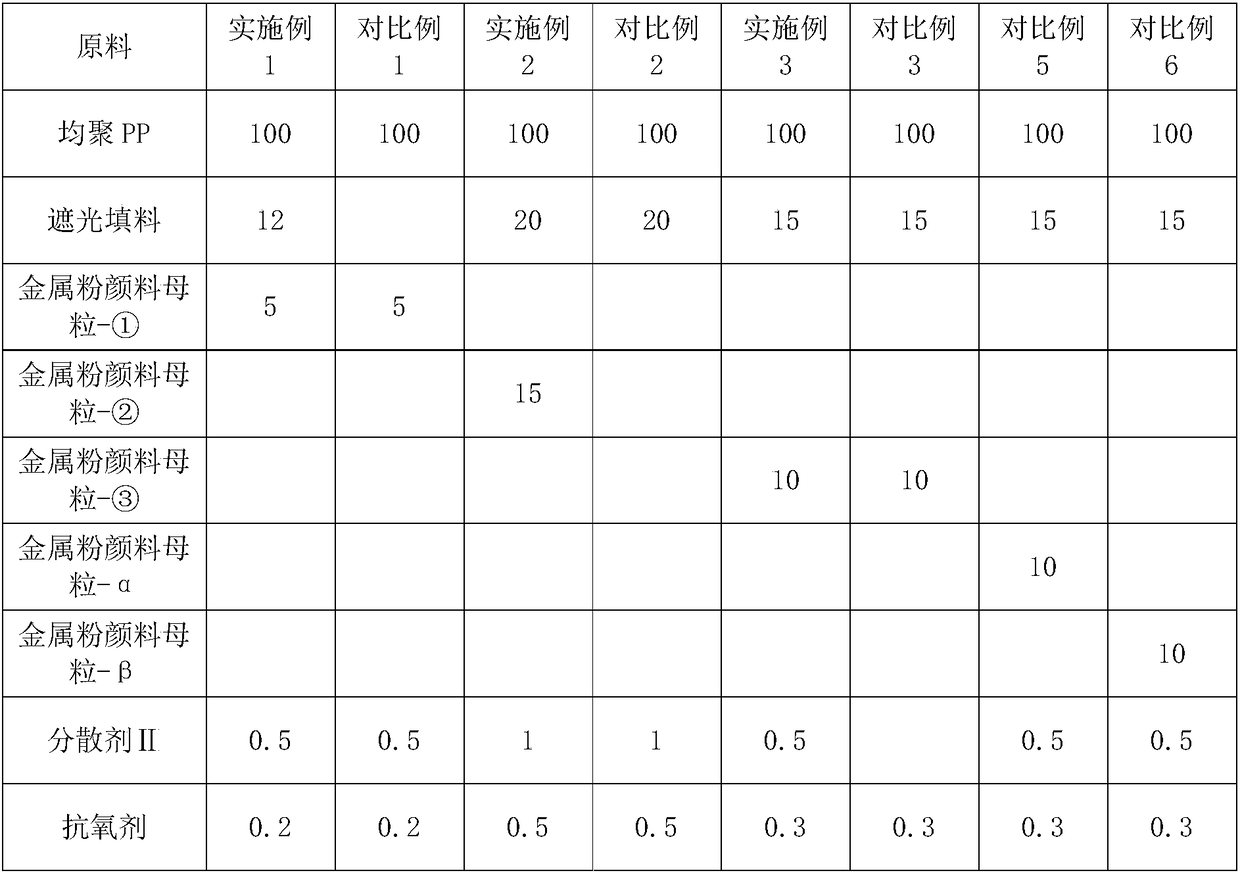

[0029] Example 1 Preparation of high shading and spray-free PP material (1)

[0030] For the high shading and spray-free PP material composition involved in this embodiment, the components and their amounts are shown in Table 1 and Table 2. Among them: the PP is a homopolymer PP, its melting index is 15g / 10min (230℃*2.16kg), the shading filler is a 3:1 mixture of silica and rutile titanium dioxide, and the silica mesh number is 3000 Mesh; in the spray-free pigment masterbatch, the matrix resin is homopolymer PP, and the melting index is 25g / 10min (230℃*2.16kg); the spray-free pigment powder is aluminum silver powder with a particle size of 10μm; dispersant I is silicone Masterbatch and stearic acid amide are compounded according to the weight ratio of 1:2. The agglomerate particle size D50 of silicone masterbatch is 500-600nm; the sizing agent is silane coupling agent KH550; dispersant Ⅱ is stearic acid amide ; Antioxidant is a compound of hindered phenolic antioxidant and phosp...

Embodiment 2

[0033] Example 2 Preparation of high shading and spray-free PP material (2)

[0034] For the high shading and spray-free PP material composition involved in this embodiment, the components and their amounts are shown in Table 1 and Table 2. Among them: the PP is a homopolymer PP, its melting index is 15g / 10min (230℃*2.16kg), the shading filler is a 3:1 mixture of silica and rutile titanium dioxide, and the silica mesh number is 3000 Mesh; in the spray-free pigment masterbatch, the matrix resin is homopolymer PP, and the melting index is 25g / 10min (230℃*2.16kg); the spray-free pigment powder is aluminum silver powder with a particle size of 10μm; dispersant I is silicone Masterbatch and stearic acid amide are compounded according to the weight ratio of 1:2. The agglomerate particle size D50 of silicone masterbatch is 500-600nm; the sizing agent is silane coupling agent KH550; dispersant Ⅱ is stearic acid amide ; Antioxidant is a compound of hindered phenolic antioxidant and phos...

Embodiment 3

[0037] Example 3 Preparation of high shading and spray-free PP material (3)

[0038] For the high shading and spray-free PP material composition involved in this embodiment, the components and their amounts are shown in Table 1 and Table 2. Among them: the PP is a homopolymer PP, its melting index is 15g / 10min (230℃*2.16kg), the shading filler is a 3:1 mixture of silica and rutile titanium dioxide, and the silica mesh number is 3000 Mesh; in the spray-free pigment masterbatch, the matrix resin is homopolymer PP, and the melting index is 25g / 10min (230℃*2.16kg); the spray-free pigment powder is aluminum silver powder with a particle size of 10μm; dispersant I is silicone Masterbatch and stearic acid amide are compounded according to the weight ratio of 1:2. The agglomerate particle size D50 of silicone masterbatch is 500-600nm; the sizing agent is silane coupling agent KH550; dispersant Ⅱ is stearic acid amide ; Antioxidant is a compound of hindered phenolic antioxidant and phos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt finger | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com