A kind of high shading spray-free PP material and preparation method thereof

A spray-free, high shading technology, applied in the field of spray-free materials, can solve the problem of inability to know the shading effect, achieve good dispersion and material shading, improve shading, and relieve flow marks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

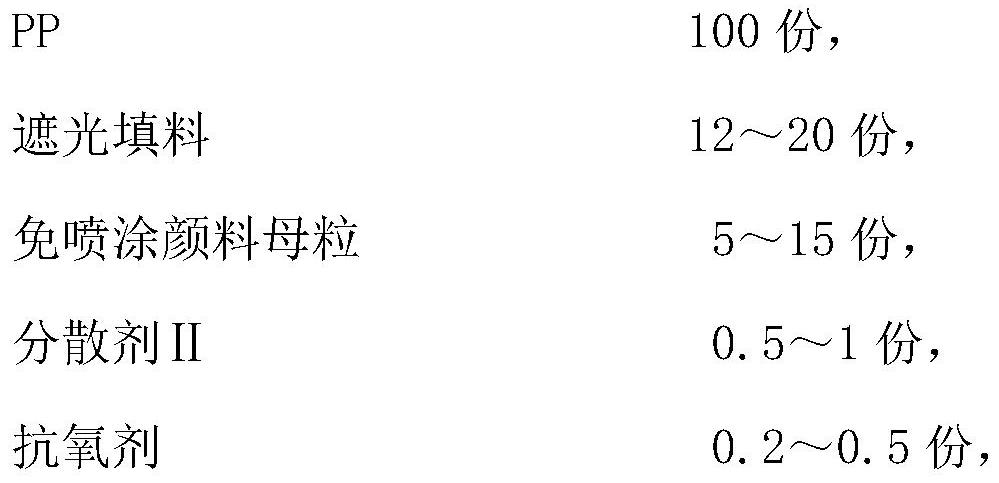

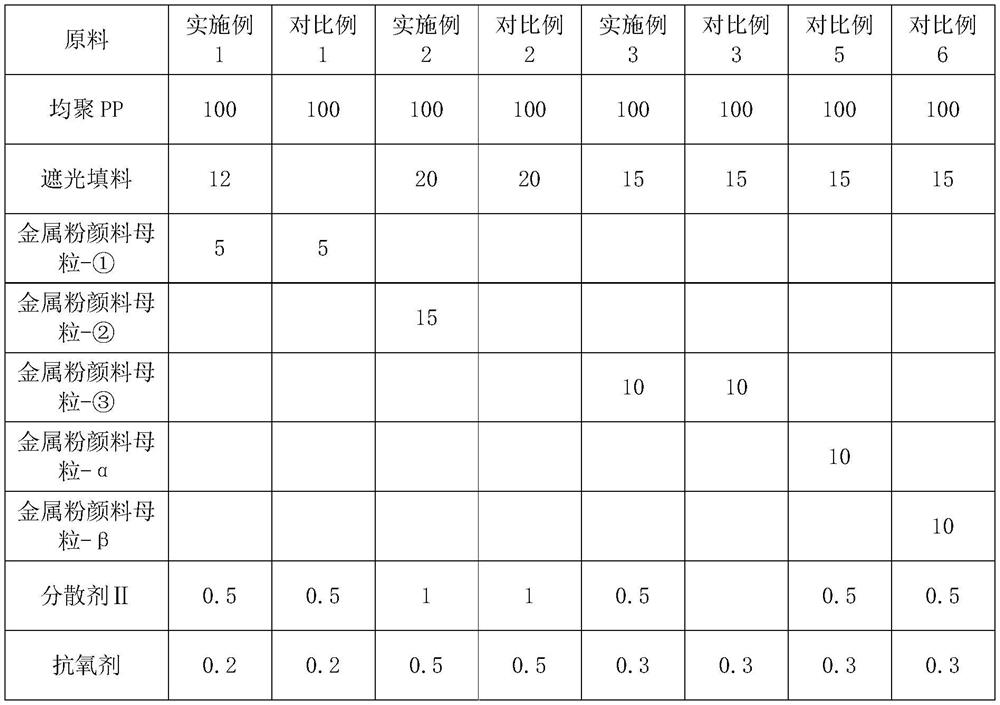

[0029] Example 1 Preparation of high shading free spray PP material (1)

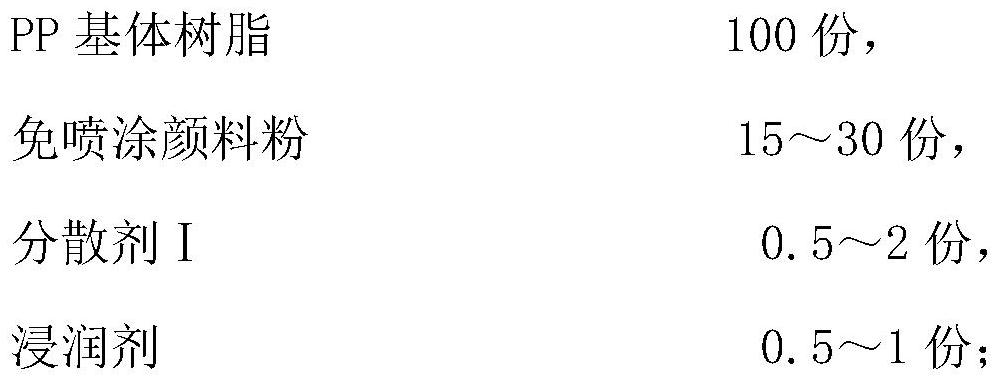

[0030] The high shielded sprayable PP material composition involved in this embodiment has the components and their usage thereof, in Table 2. Among them: The PP is a homogeneous PP having a melt index of 15 g / 10min (230 ° C * 2.16kg), the light shielding filler is silica and golden red-shaped titanium white powder in accordance with 3: 1 compound, the number of silicon is 3000 Entry; from sprayless pigment mother particles, the substrate resin is a homogeneous PP, the melt refers to 25 g / 10 min (230 ° C * 2.16 kg); the sprayed pigment powder is selected from the aluminum silver powder, which is 10 μm having a particle size of 10 μm; dispersant I is silicone Masterblic, stearate is compounded by weight ratio of 1: 2, the agitation particle diameter D50 of silicone mother particles is 500-600 nm; the wetting agent is a silane coupling agent KH550; dispersant II is stearate amide The antioxidant is a wei...

Embodiment 2

[0033] Example 2 Preparation of high shading free spray PP material (2)

[0034] The high shielded sprayable PP material composition involved in this embodiment has the components and their usage thereof, in Table 2. Among them: The PP is a homogeneous PP having a melt index of 15 g / 10min (230 ° C * 2.16kg), the light shielding filler is silica and golden red-shaped titanium white powder in accordance with 3: 1 compound, the number of silicon is 3000 Entry; from sprayless pigment mother particles, the substrate resin is a homogeneous PP, the melt refers to 25 g / 10 min (230 ° C * 2.16 kg); the sprayed pigment powder is selected from the aluminum silver powder, which is 10 μm having a particle size of 10 μm; dispersant I is silicone Masterblic, stearate is compounded by weight ratio of 1: 2, the agitation particle diameter D50 of silicone mother particles is 500-600 nm; the wetting agent is a silane coupling agent KH550; dispersant II is stearate amide The antioxidant is a wei...

Embodiment 3

[0037] Example 3 Preparation of high shading free spray PP material (3)

[0038] The high shielded sprayable PP material composition involved in this embodiment has the components and their usage thereof, in Table 2. Among them: The PP is a homogeneous PP having a melt index of 15 g / 10min (230 ° C * 2.16kg), the light shielding filler is silica and golden red-shaped titanium white powder in accordance with 3: 1 compound, the number of silicon is 3000 Entry; from sprayless pigment mother particles, the substrate resin is a homogeneous PP, the melt refers to 25 g / 10 min (230 ° C * 2.16 kg); the sprayed pigment powder is selected from the aluminum silver powder, which is 10 μm having a particle size of 10 μm; dispersant I is silicone Masterblic, stearate is compounded by weight ratio of 1: 2, the agitation particle diameter D50 of silicone mother particles is 500-600 nm; the wetting agent is a silane coupling agent KH550; dispersant II is stearate amide The antioxidant is a wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com