Multilayer anisotropic conductive cloth adhesive tape, and manufacturing method thereof

A technology of conductive cloth and conductive particles, which is applied in the direction of conductive materials, conductive materials, conductive adhesives, etc., can solve the problems of uneven powder distribution, poor metal flexibility, and hidden dangers of plate explosion, and achieve good flexibility and Wear resistance, avoid poor conduction effect, good anisotropic conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

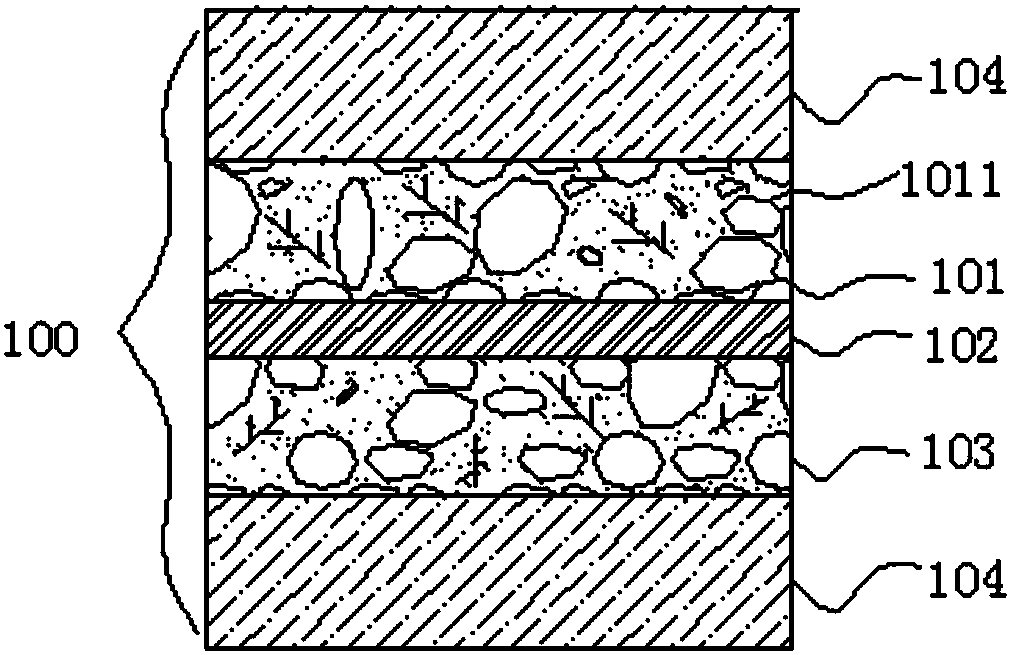

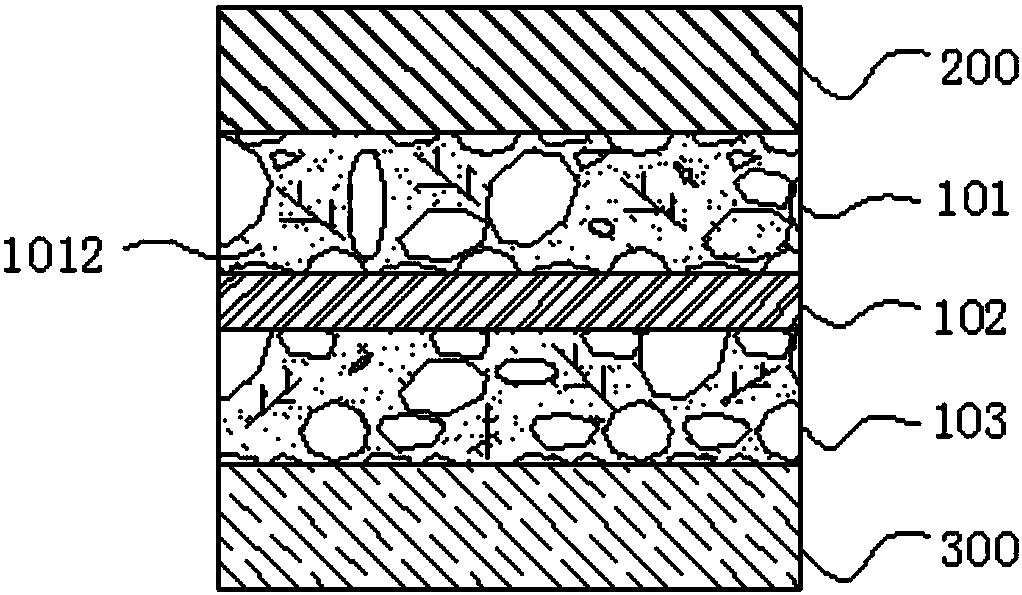

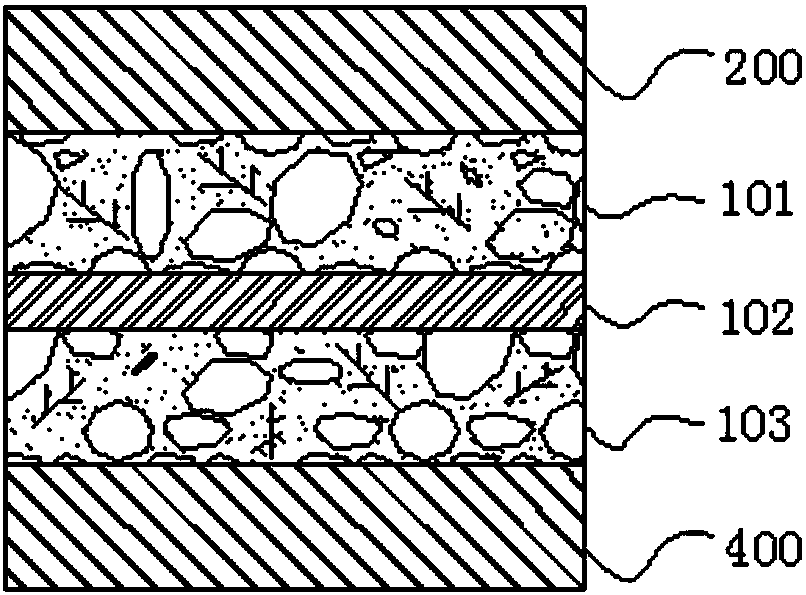

[0051]Embodiment: a kind of multi-layer anisotropic conductive cloth glue 100, such as figure 1 As shown, it includes an upper conductive adhesive layer 101, a conductive cloth layer 102 and a lower conductive adhesive layer 103, and the conductive cloth layer 102 is formed between the upper conductive adhesive layer 101 and the lower conductive adhesive layer 103 ;

[0052] The thickness of the upper conductive adhesive layer 101 is 20-40 μm, the thickness of the lower conductive adhesive layer 103 is 20-40 μm, and both the upper conductive adhesive layer 101 and the lower conductive adhesive layer 103 include metal Conductive particles 1011, the metal conductive particles are at least two of dendritic metal powder, acicular metal powder, flake metal powder and spherical metal powder, the particle size of the metal conductive particles is 2-50 μm;

[0053] The thickness of the conductive cloth layer 102 is 5-30 μm, the upper and lower sides of the conductive cloth layer 102 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com