Composite conductive adhesive film and manufacturing method thereof

A composite conductive and conductive adhesive layer technology, which is applied in the direction of conductive adhesives, cable/conductor manufacturing, conductive layers on insulating carriers, etc., can solve the problems of low transparency of ACF, limited amount of conductive particles, and low conductivity of carbon fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

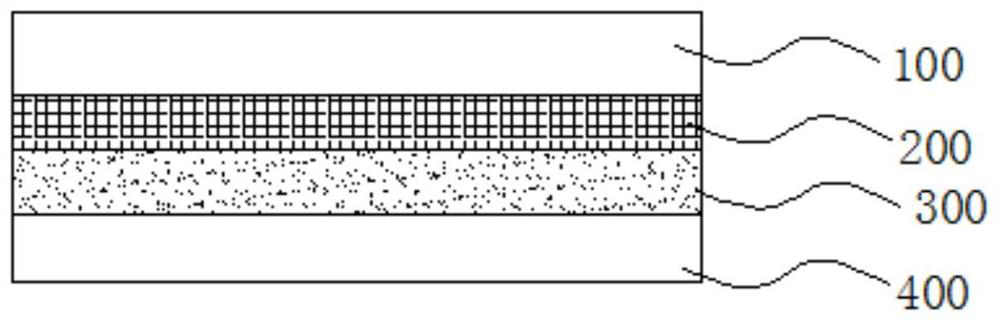

[0047] Embodiment: a kind of composite conductive adhesive film 100, such as Figures 1 to 4 As shown, it includes an upper adhesive layer 100, a reinforcing layer 200, a conductive adhesive layer 300 and a lower adhesive layer 400, the reinforcing layer is located between the upper adhesive layer and the conductive adhesive layer, and the conductive adhesive layer is located Between the reinforcing layer and the lower adhesive layer;

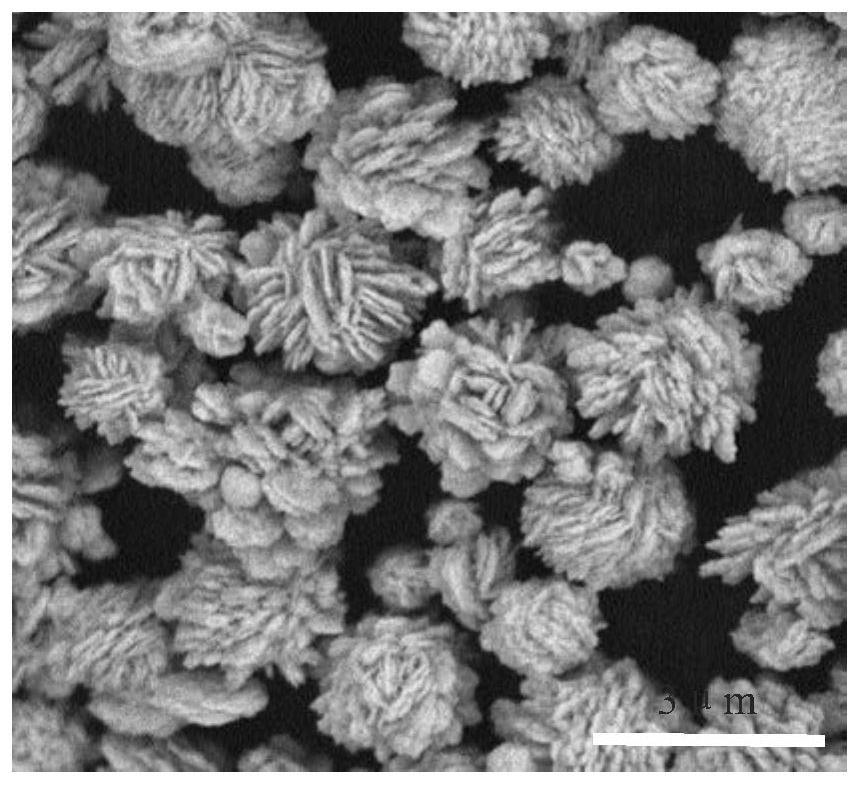

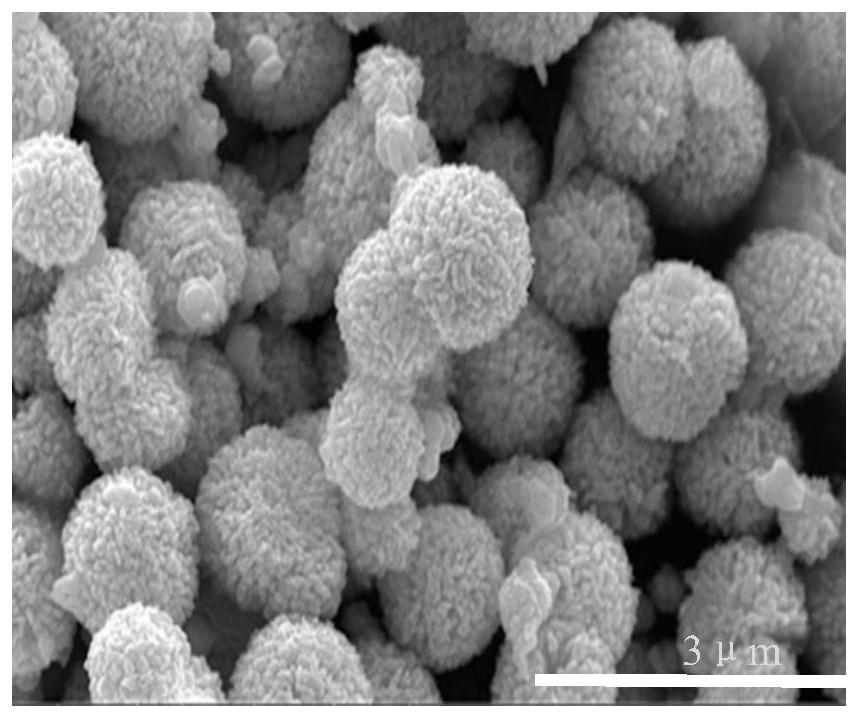

[0048] The thickness of the upper adhesive layer is 25-35 μm, the thickness of the lower adhesive layer is 25-35 μm, the conductive adhesive layer includes conductive particles, the matrix of the conductive particles is polymer particles, and the surface of the polymer particles is covered with One layer of alloy layer is covered, and one layer of single metal layer is coated on the alloy layer, the alloy layer is a copper-nickel alloy layer, and the single metal layer is a silver layer or a gold layer; the particle size of the polymer particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com