Composite high shielding thin electromagnetic interference shielding film and preparation method thereof

An electromagnetic interference shielding and shielding technology, applied in the field of thinned shielding film for FPC and its preparation, can solve the problems of poor operability, difficulty in peeling off the release film on the outer layer of the shielding film, etc., and achieve good filling area and low water absorption efficiency, enhanced shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

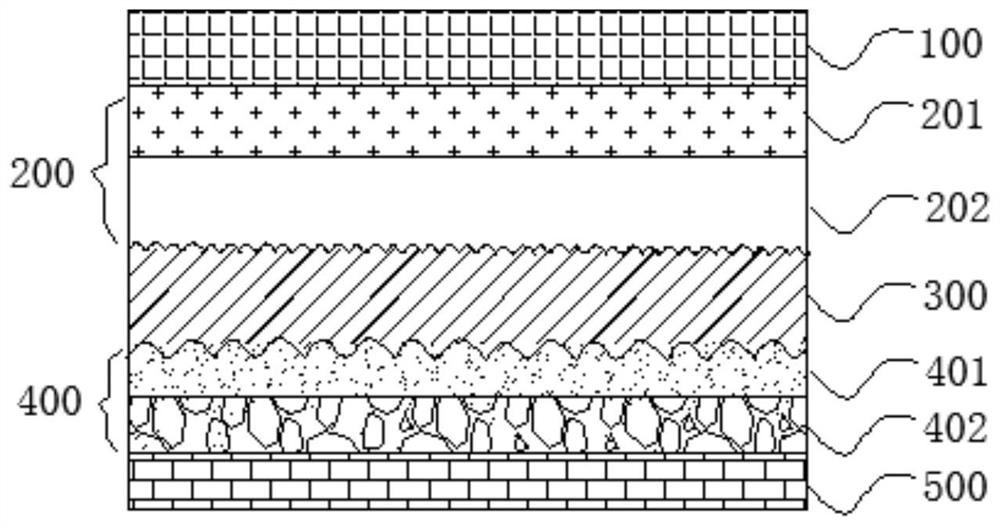

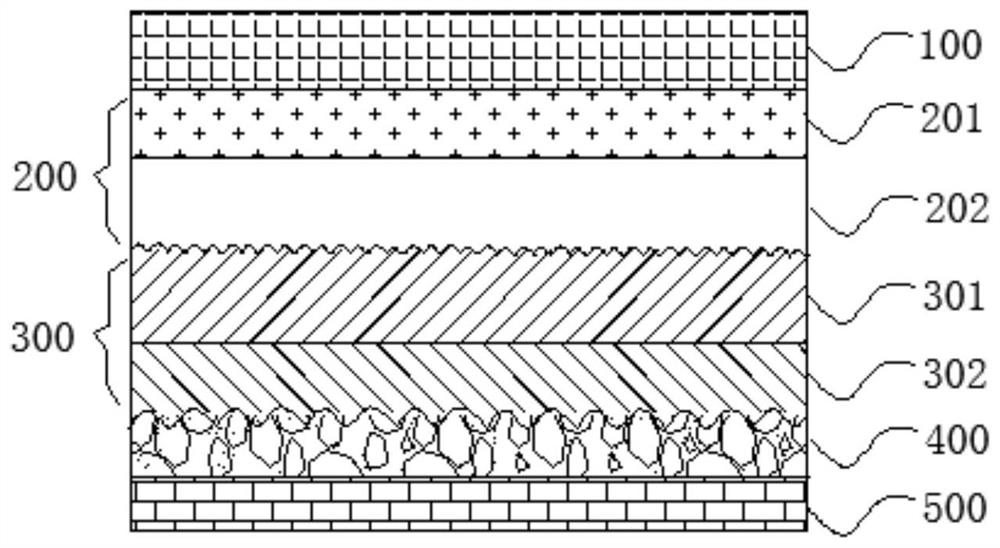

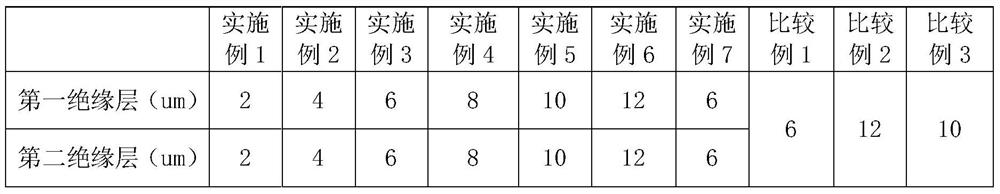

[0070] Embodiment: a kind of composite type high shielding thin electromagnetic interference shielding film, such as figure 1 with figure 2 As shown, it includes a black composite insulating layer 200, a metal layer 300 and a conductive adhesive layer 400, and the metal layer 300 is between the black composite insulating layer 200 and the conductive adhesive layer 400;

[0071] The black composite insulating layer 200 includes a first insulating layer 201 and a second insulating layer 202, and the second insulating layer 202 is located between the first insulating layer 201 and the metal layer 300;

[0072] The hardness of the black composite insulating layer 200 is HB-5H;

[0073] The glossiness of the first insulating layer 201 is 0-60% (60°);

[0074] The side of the second insulating layer 202 in contact with the metal layer 300 is a rough surface with an Rz value of 0.01-0.5 (excluding 0.5) μm;

[0075] The total thickness of the electromagnetic interference shielding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com