Economical high-plasticity 360MPa grade structural steel plate and manufacturing method thereof

A technology for structural steel plates and manufacturing methods, which is applied in the field of economical high-plasticity 360MPa structural steel plates and its manufacturing, can solve problems such as deterioration of welding performance, low elongation of steel plates, poor welding performance, etc., and achieve strong adaptability and popularization, The effect of streamlining processing technology and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

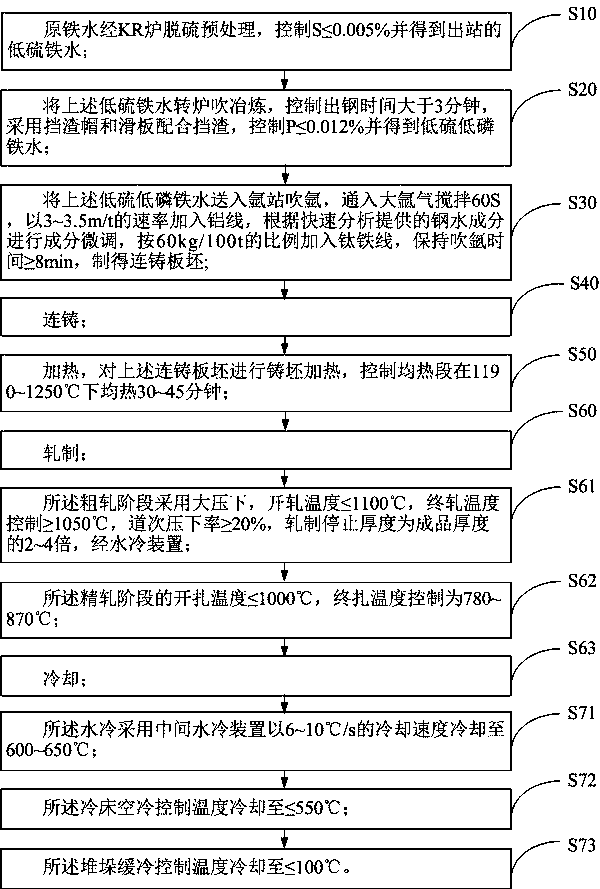

Method used

Image

Examples

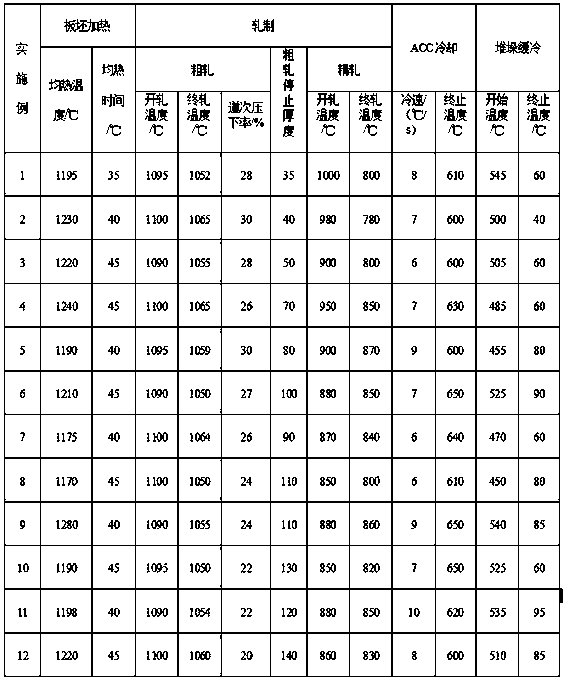

Embodiment 1

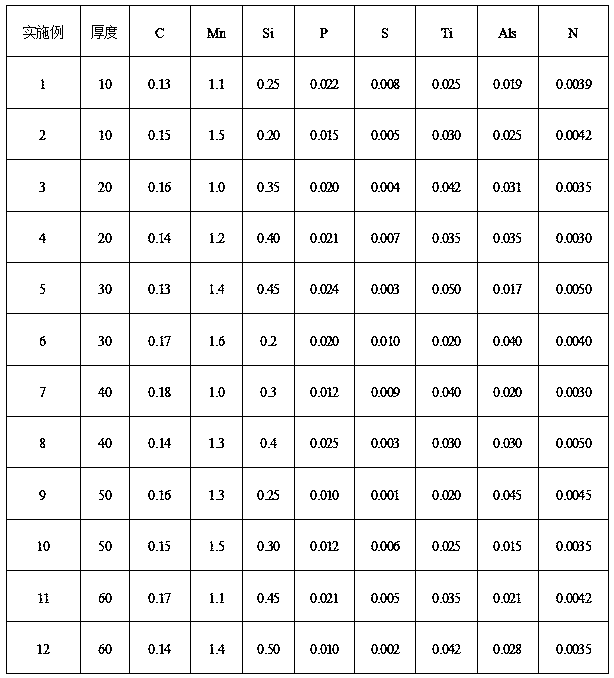

[0054] The components and weight percentages of the economical high-plasticity 360MPa grade structural steel plate include: C: 0.13%, Mn: 1.0%, Si: 0.20%, P: 0.015%, S: 0.005%, Ti: 0.025%, Als : 0.0195%, N: 0.0039%, the rest is Fe and unavoidable impurity elements.

[0055] The manufacturing method of the economical high plasticity 360MPa grade structural steel plate comprises the following steps:

[0056] (1) The original molten iron is desulfurized and pretreated by the KR furnace, and the S≤0.005% is controlled to obtain the low-sulfur molten iron out of the station;

[0057] (2) The above-mentioned low-sulfur molten iron is smelted in a converter, and the tapping time is controlled to be longer than 3 minutes. The slag-stopping cap and the slide plate are used to cooperate with the slag-stopping, and the P≤0.012% is controlled to obtain low-sulfur and low-phosphorus molten iron;

[0058] (3) Send the above-mentioned low-sulfur and low-phosphorus molten iron into the argon...

Embodiment 2

[0065] The components and weight percentages of the economical high-plasticity 360MPa grade structural steel plate include: C: 0.15%, Mn: 1.5%, Si: 0.25%, P: 0.022%, S: 0.008%, Ti: 0.030%, Als : 0.025%, N: 0.0042%, the rest is Fe and unavoidable impurity elements.

[0066] The manufacturing method of the economical high plasticity 360MPa grade structural steel plate comprises the following steps:

[0067] (1) The original molten iron is desulfurized and pretreated by the KR furnace, and the S≤0.005% is controlled to obtain the low-sulfur molten iron out of the station;

[0068] (2) The above-mentioned low-sulfur molten iron is smelted in a converter, and the tapping time is controlled to be longer than 3 minutes. The slag-stopping cap and the slide plate are used to cooperate with the slag-stopping, and the P≤0.012% is controlled to obtain low-sulfur and low-phosphorus molten iron;

[0069] (3) Send the above-mentioned low-sulfur and low-phosphorus molten iron into the argon ...

Embodiment 3

[0076] The components and weight percentages of the economical high-plasticity 360MPa grade structural steel plate include: C: 0.14%, Mn: 1.0%, Si: 0.35%, P: 0.020%, S: 0.004%, Ti: 0.035%, Als : 0.031%, N: 0.0030%, the rest is Fe and unavoidable impurity elements.

[0077] The manufacturing method of the economical high plasticity 360MPa grade structural steel plate comprises the following steps:

[0078] (1) The original molten iron is desulfurized and pretreated by the KR furnace, and the S≤0.005% is controlled to obtain the low-sulfur molten iron out of the station;

[0079] (2) The above-mentioned low-sulfur molten iron is smelted in a converter, and the tapping time is controlled to be longer than 3 minutes. The slag-stopping cap and the slide plate are used to cooperate with the slag-stopping, and the P≤0.012% is controlled to obtain low-sulfur and low-phosphorus molten iron;

[0080] (3) Send the above-mentioned low-sulfur and low-phosphorus molten iron into the argon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com