A sealing method suitable for high-temperature nitrogen injection into coal seam drilling

A nitrogen and coal seam technology, applied in the direction of sealing/packing, drill pipe, drill pipe, etc., to achieve good airtightness, ensure heat insulation effect, and facilitate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below.

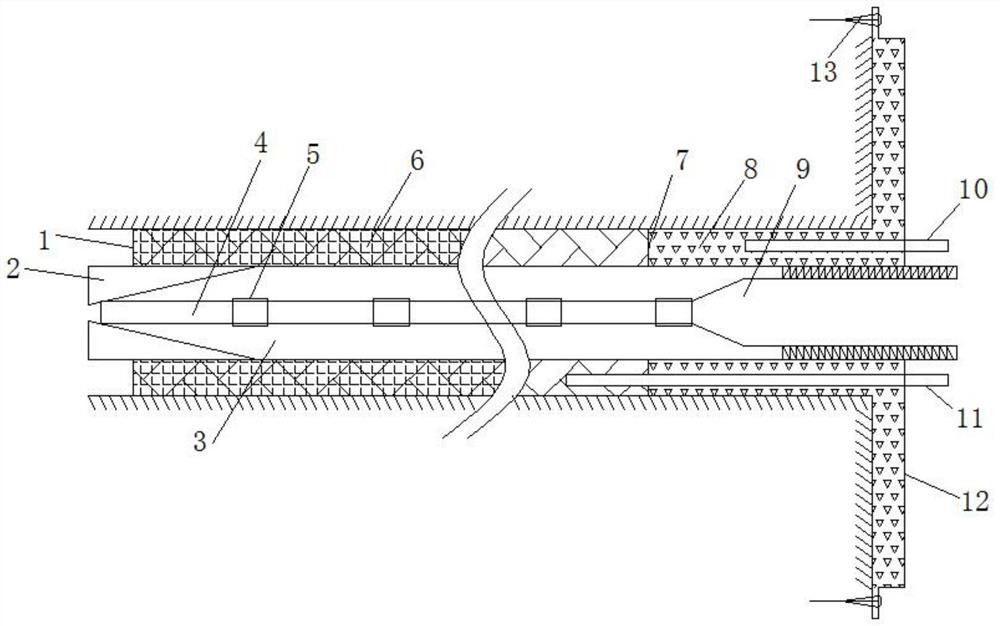

[0019] Such as figure 1 Shown, in the middle part of the coal seam, the high-temperature nitrogen gas injection drilling is arranged, and the drilling diameter is 89mm; then the specific steps of the present invention are:

[0020] A. Fix a group of rubber fixing devices 2 inside the first PE pipe 3, each group of rubber fixing devices 2 is composed of two symmetrically arranged rubber fixing blocks, the gap between the two rubber fixing blocks is trumpet-shaped, and The minimum gap is 14mm, and the two ends of the PE pipe are respectively provided with internal and external threads that match each other, and then the iron pipe 4 with external threads at both ends is inserted into the first PE pipe 3 and passed through the rubber fixing device 2 Fixed; the PE pipe used is 60mm in outer diameter and 4m in length; the iron pipe 4 is 15mm in outer diameter and 4m in length.

[0021] B. Wrap the raw tape on the exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com