A multi-tube helical pulse detonation engine

A kind of engine and spiral technology, applied in the field of aviation propulsion, can solve the problems of complex structure, unfavorable engine heat dissipation, etc., and achieve the effect of speeding up the reaction rate, simple structure, and reducing flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

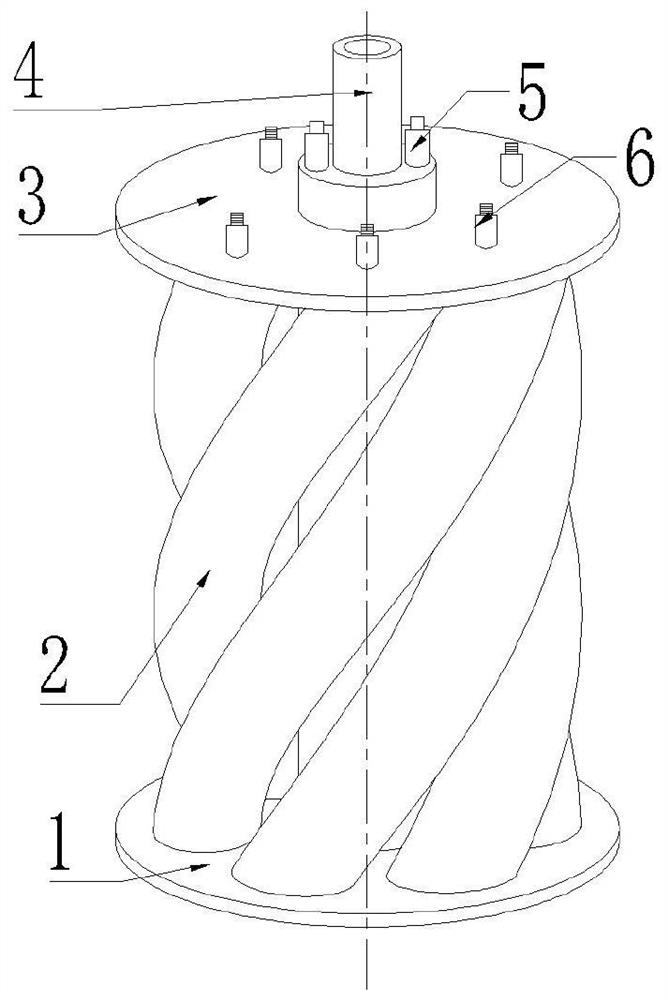

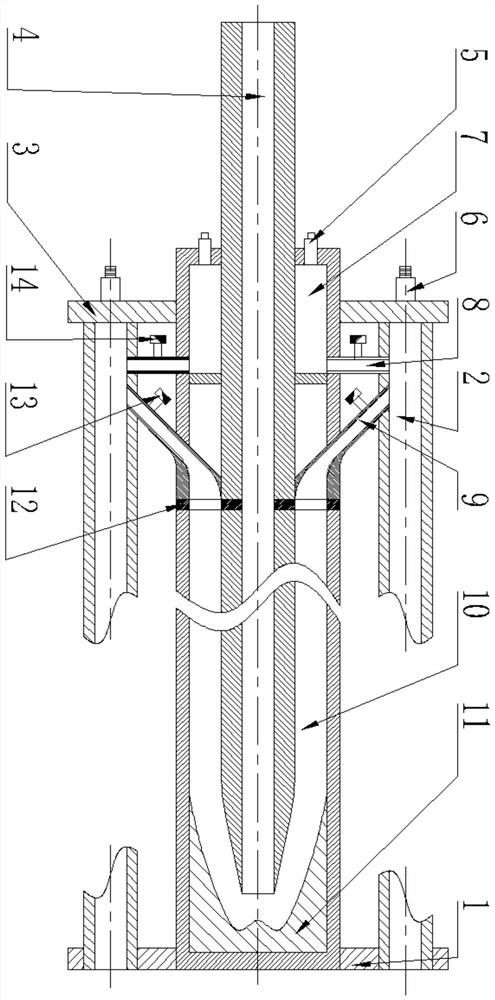

[0028] Such as figure 1 and figure 2 As shown, the multi-tube helical pulse detonation engine described in the present invention includes an inlet gas distribution device and an engine body; the engine body includes an engine outlet cover plate 1, a spiral detonation tube 2, an engine closed cover plate 3 and an air chamber ; The air chamber is fixed between the engine outlet cover plate 1 and the engine closed cover plate 3, as figure 2 As shown, one end of the air chamber passes through the engine closed cover plate 3, and the other end of the air chamber is flush with the engine outlet cover plate 1. Some said spiral detonation tubes 2 are uniformly distributed and fixed between the engine outlet cover plate 1 and the engine closed cover plate 3 according to the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com