A fuel storage device with high safety performance for new energy

A safety performance and fuel storage technology, which is applied in mechanical equipment, gas treatment/storage purposes, gas treatment/storage effects, etc., can solve problems that affect the personal safety of residents, life threats to drivers, and methane gas leakage, etc., to achieve safe use Convenience, avoiding temperature rise, and preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

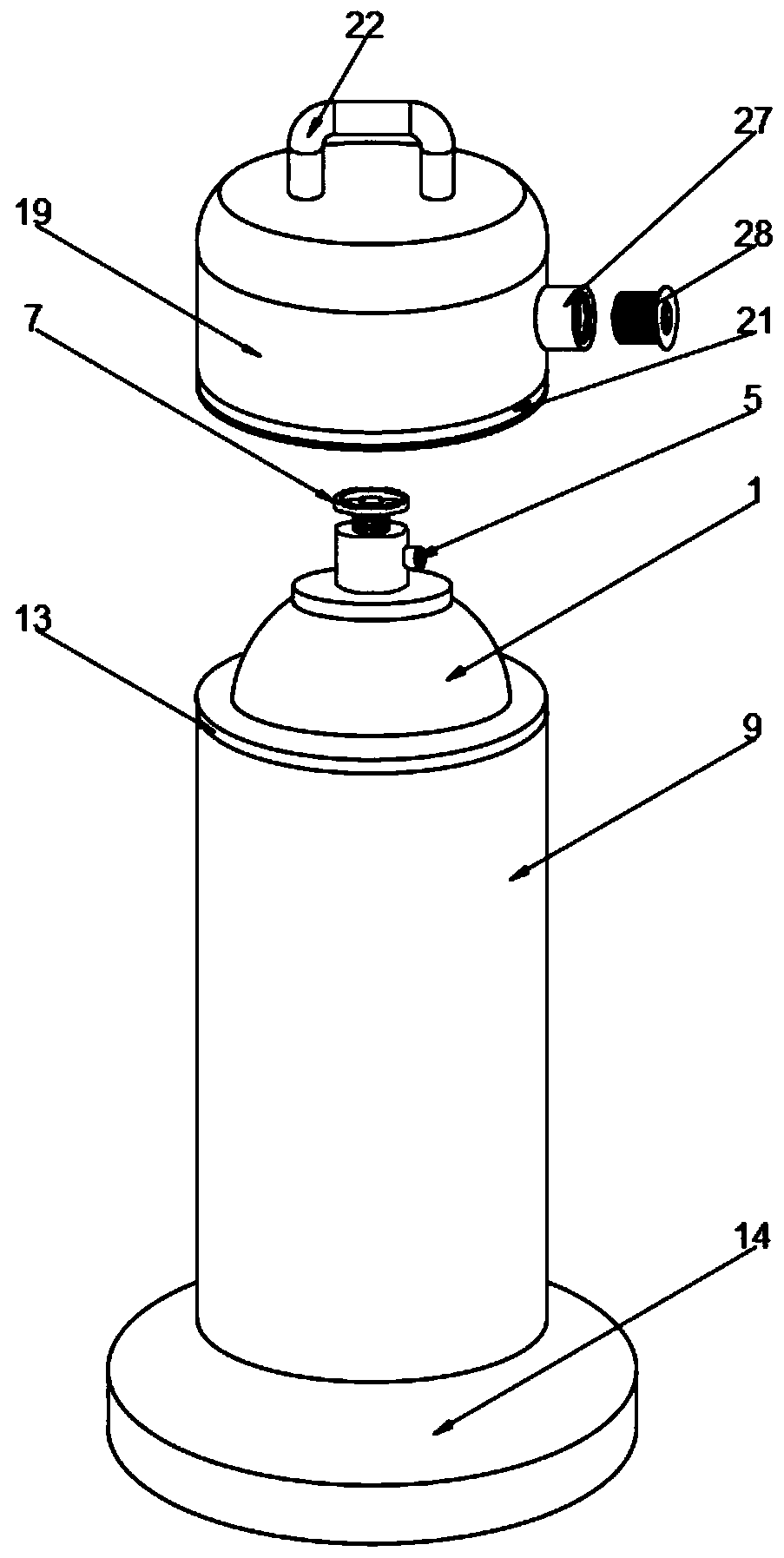

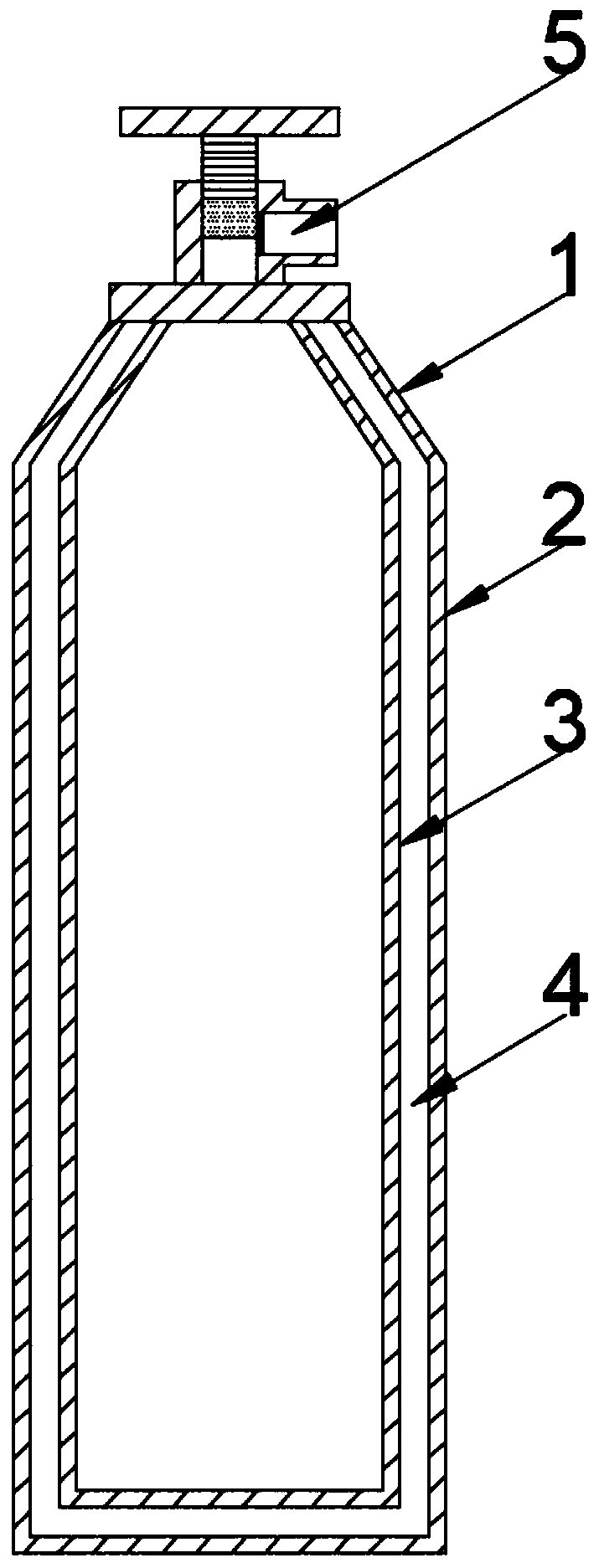

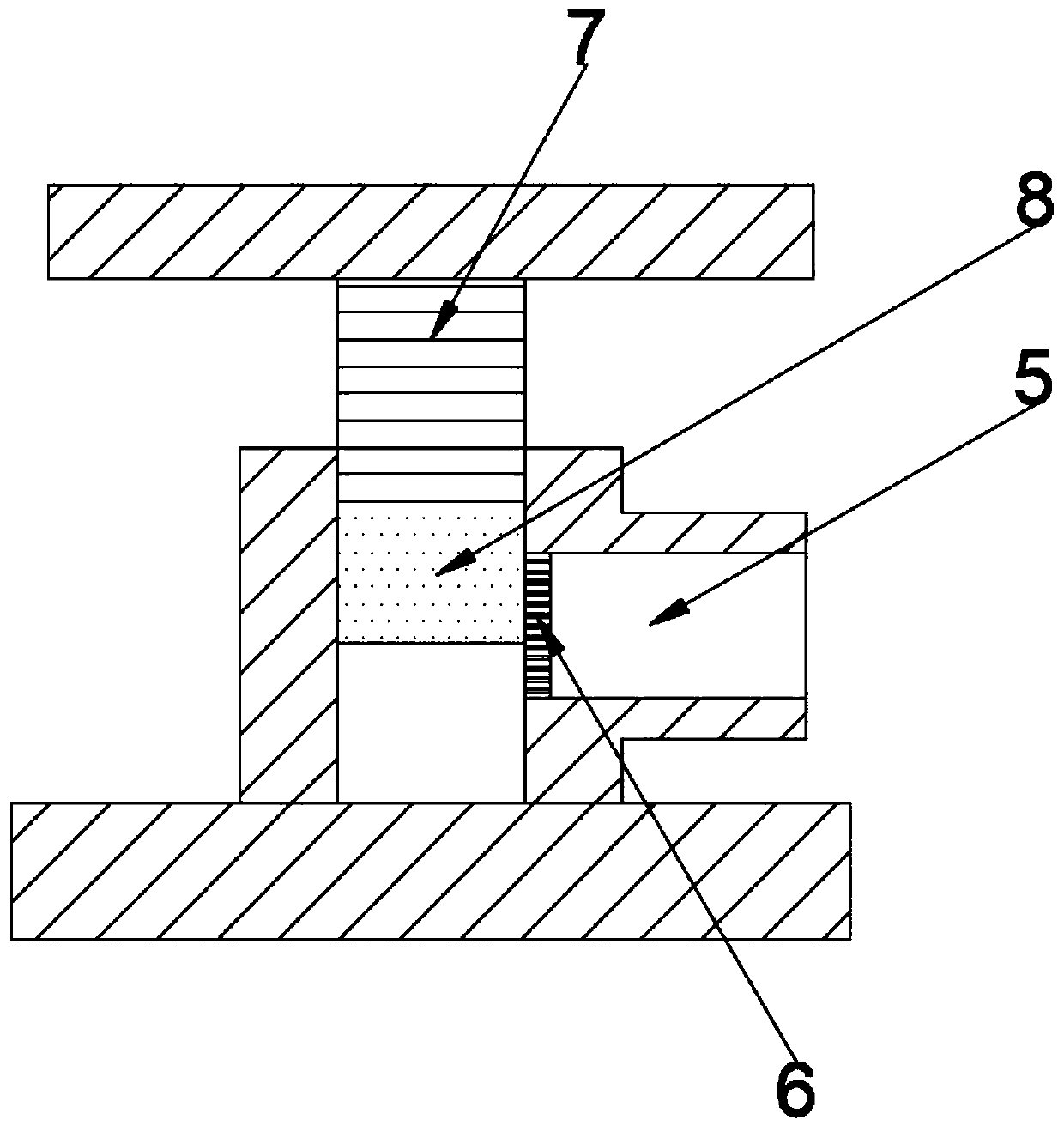

[0033] Example: such as Figure 1-8As shown, the present invention provides a technical solution, a fuel storage device with high safety performance for new energy, including a tank body 1, an outer tank body 2, an inner tank body 3, a leak-proof layer 4, a methane outlet 5, and a screen 6. Valve 7, sealing rubber block 8, protective sleeve 9, first outer shell 10, first inner shell 11, buffer spring 12, first magnet 13, shock-absorbing base 14, shock-absorbing rubber pad 15, shock-absorbing cavity Chamber 16, damping spring 17, damping rubber tube 18, sealing cover 19, sealing rubber ring 20, second magnet 21, handle 22, second outer shell 23, buffer rubber 24, second inner shell 25, methane leakage Alarm 26, connecting port 27, sealing bolt 28, thread 29 and sealing sponge 30, outer tank body 2 is welded on the outside of tank body 1, inner tank body 3 is welded on the inner side of tank body 1, outer tank body 2 and inner tank body 3 There is a leak-proof layer 4 between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com