Automatic measuring method of film hot-shrinkage rate

A technology of thermal shrinkage and automatic measurement, applied in measuring devices, material thermal expansion coefficients, instruments, etc., can solve the problems of high labor intensity, large human interference, and large limitations, so as to reduce human measurement errors and overcome large human interference. , the effect of fast and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

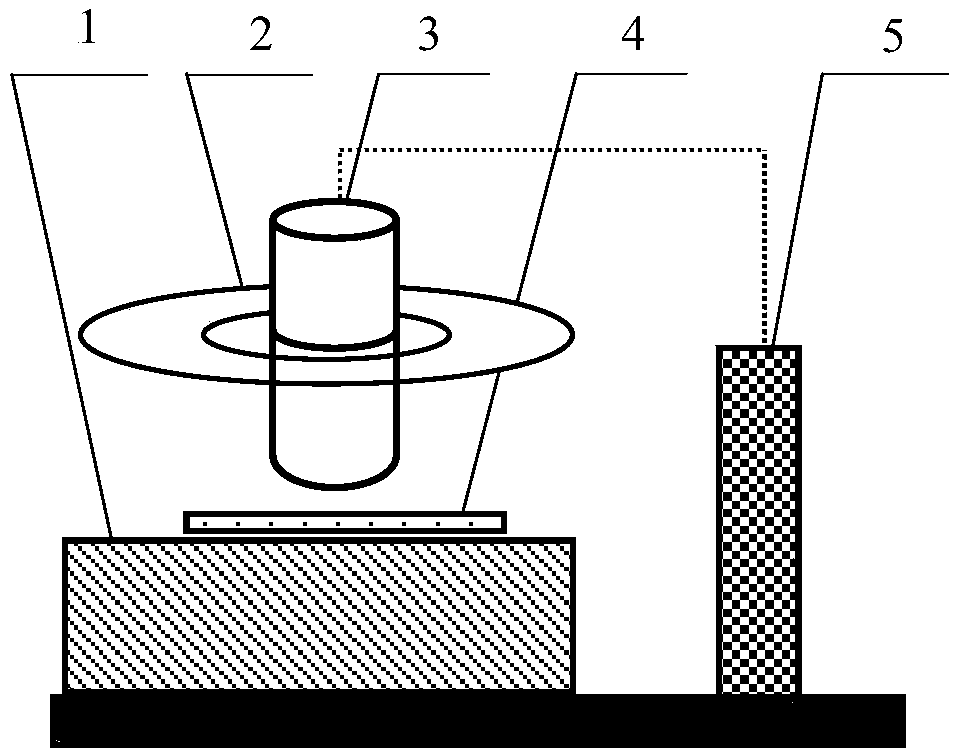

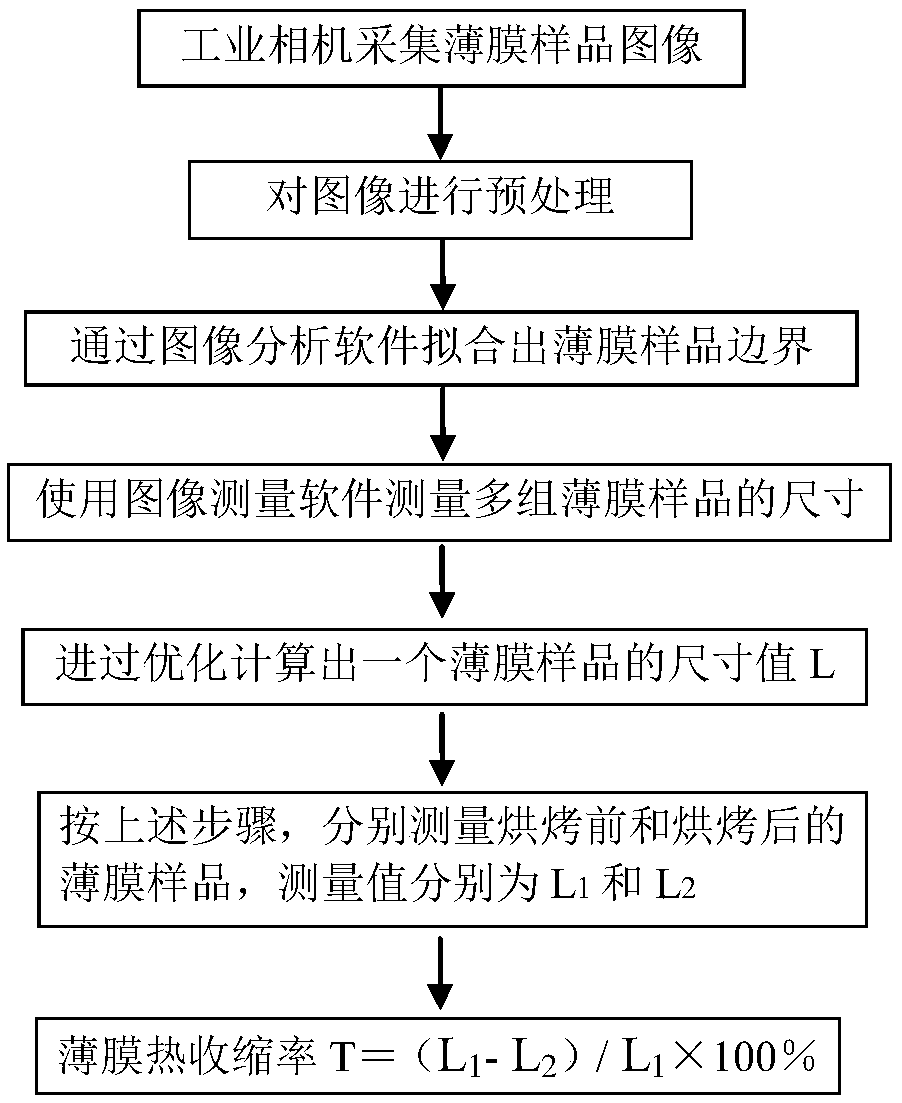

Method used

Image

Examples

Embodiment example 1

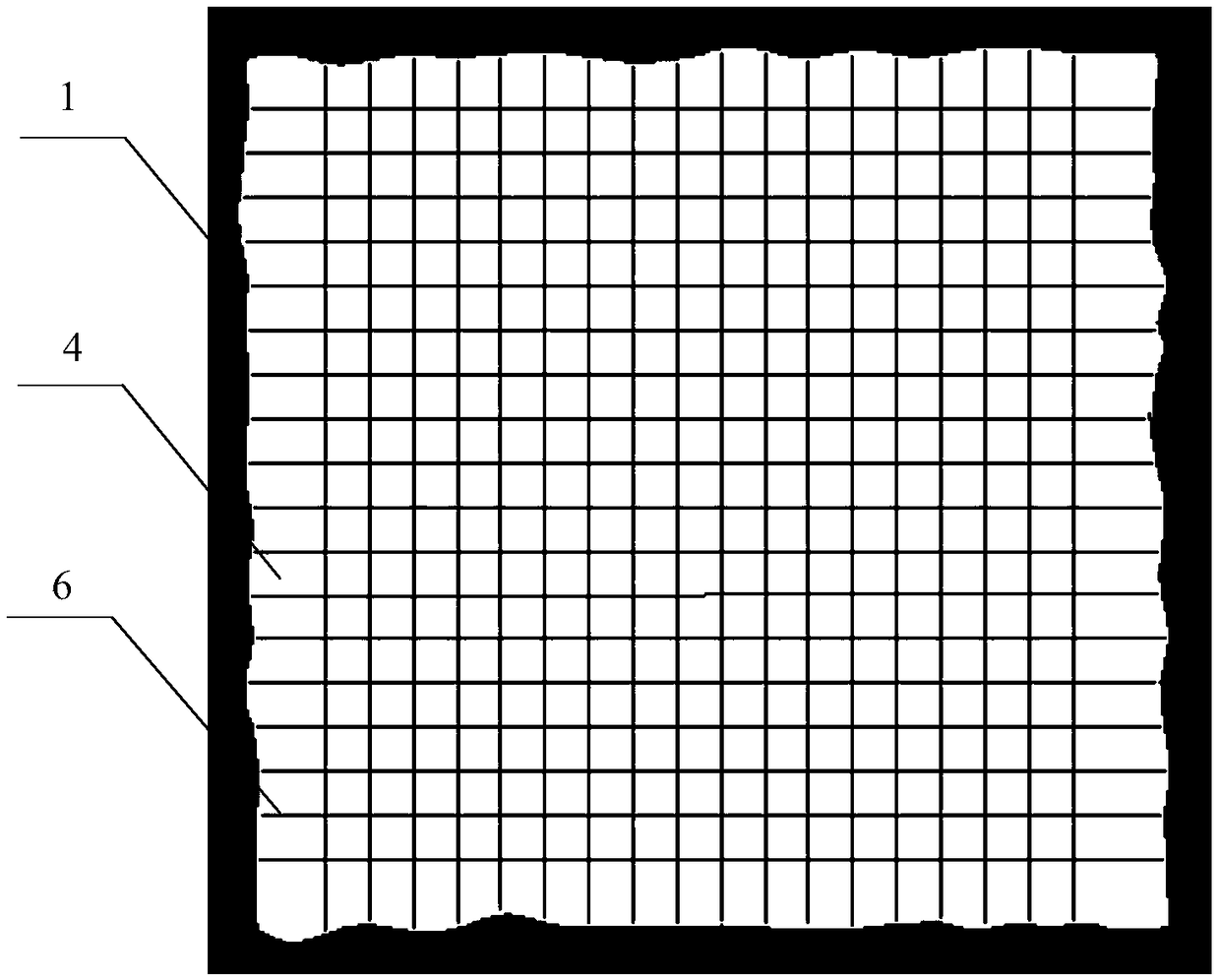

[0046] The appearance of the film fixed platform is dyed black or dark to increase the contrast between the film boundary and the fixed platform, so as to more clearly identify the film boundary and provide a guarantee for the accuracy of the measurement, such as figure 2 Shown.

Embodiment example 2

[0048] The image of the film sample obtained by the industrial camera is processed as figure 2 As shown, first divide 20 of them (the middle are equally divided), and then measure the length of each divided line (the value is shown in Table 1 below), and then remove its outliers (such as removing the smallest 5 values and the largest 5 values), and finally calculate the average value of the remaining data (shown in Table 2) after the elimination, and get the final measurement value (L2 vertical = 90.16 and L2 horizontal = 94.53), and use the film heat shrinkage rate calculation formula T = ( L1-L2) / L1×100% calculate the thermal shrinkage rate of the film (assuming L1 vertical=100 and L1 horizontal=100), T vertical=(100-90.16) / 100×100%=9.84%; T horizontal=(100 -94.53) / 100×100%=5.47%. Through multiple sets of measurements, abnormal values can be effectively eliminated, measurement errors can be avoided, measurement accuracy can be improved, and longitudinal and transverse le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com