Embedded robot apparatus of unmanned aerial vehicle for multi-split high-voltage wire inspection and method

A high-voltage wire and robot technology, applied in the field of multi-split high-voltage wire inspection drone embedded robot device, can solve the problems of inability to accurately observe wires, power consumption, damage to wires, etc., and achieve convenient and fast inspection of workpieces , Reduce power consumption, high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

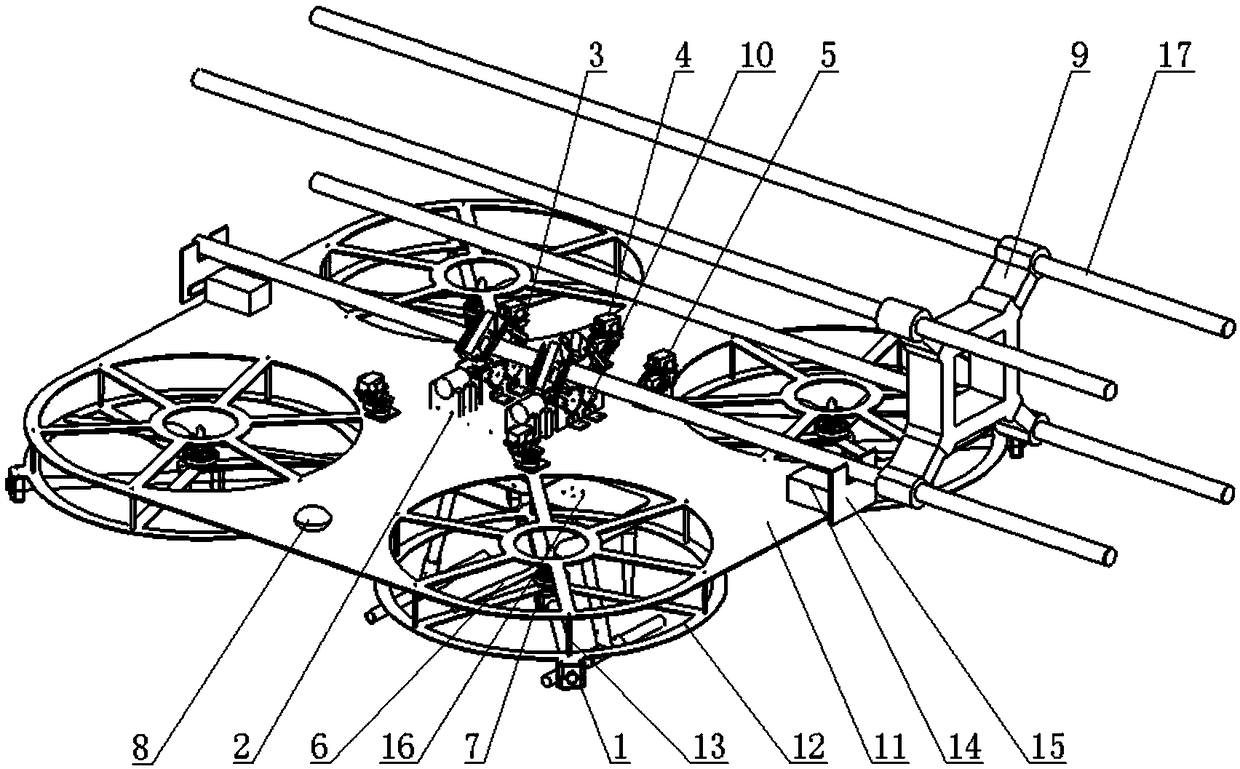

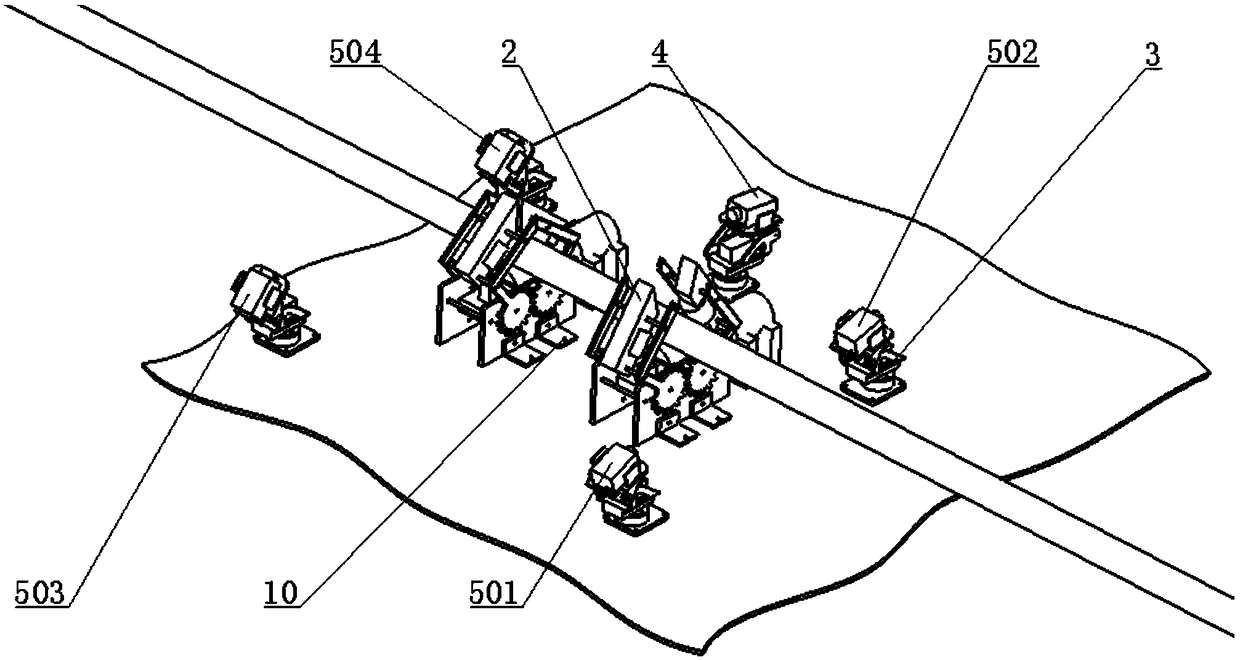

[0044] Before the inspection begins, the robotic device adopts different inspection modes according to the different splitting modes of the high-voltage wire 17, and adjusts four thermal-sensing cameras 5 angles to take pictures according to the different inspection modes.

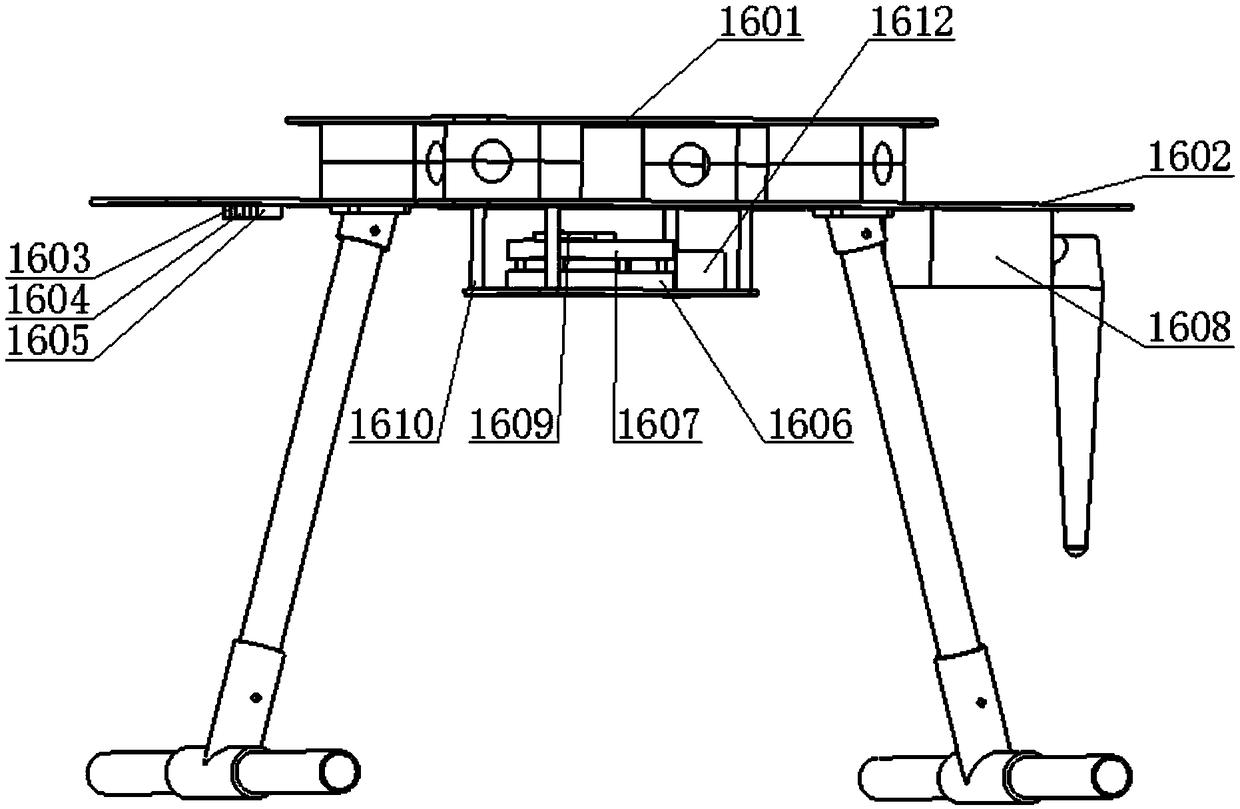

[0045] Such as Figure 4 As shown, when starting the inspection, the blade 6 of the robot device rotates and flies to the vicinity of the high-voltage wire 17, and then the robot moves close to the high-voltage wire 17 so that the mechanical gripper 2 grabs the high-voltage wire 17, and then the blade 6 stops rotating. , the brushless motor 7 is turned off, and the robot device is driven by the mechanical hand 2 along the high-voltage electric wire 17 for inspection, and the full-color camera 4 and the thermal sensor camera 5 transmit the captured pictures to the signal processor 1606; During the inspection, it is found that the wire is damaged, and the specific location of the damage is recorded.

[0046...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com