In-situ-doped cobalt fenton catalyst as well as synthetic method and application thereof

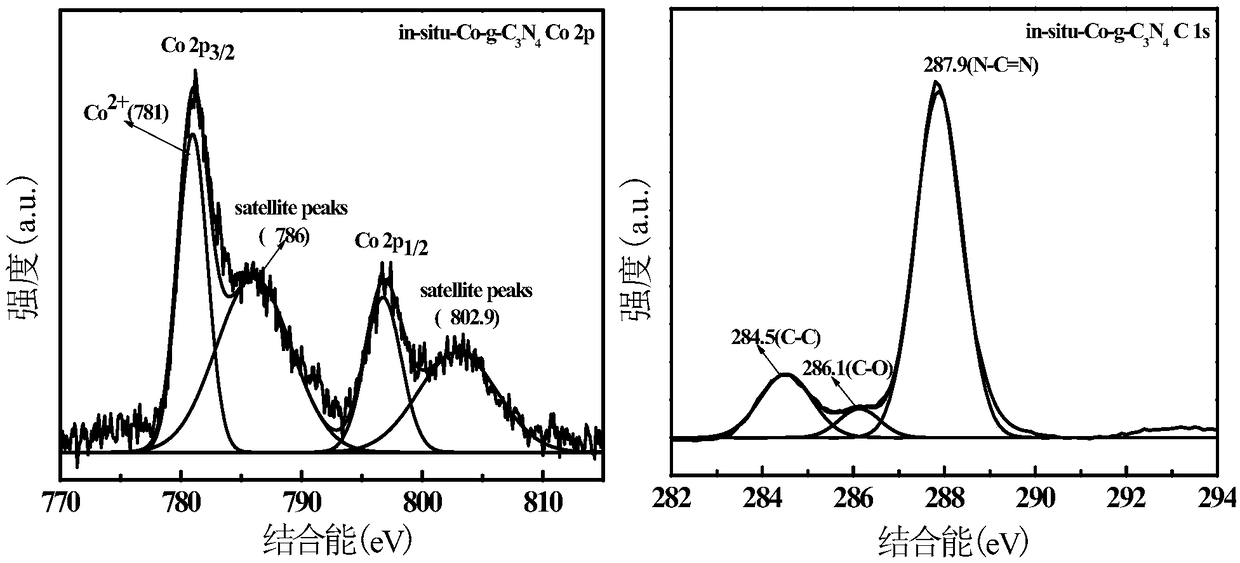

A technology of in-situ doping and synthesis methods, which is applied in chemical instruments and methods, catalysts for physical/chemical processes, water treatment of special compounds, etc., and can solve the problems of poor stability, large metal ion dissolution, and low utilization rate of hydrogen peroxide. , to achieve good stability, strong ability to activate H2O2, and easy recovery and recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] An in-situ-Co-g-C 3 N 4 The synthetic method, it comprises the steps:

[0038] (1) 0.04mol melamine and 0.004mol cobalt chloride hexahydrate are dissolved in 20ml absolute ethanol to obtain solution A;

[0039] (2) Place the solution A on a heat-collecting constant temperature magnetic stirrer and stir evenly, and evaporate to dryness in a water bath at 70° C. to obtain a solid product A;

[0040] (3) Transfer the solid product A obtained by evaporating to dryness in step (2) into an oven, dry it completely at 70° C., and grind it evenly;

[0041] (4) The uniformly ground solid product A is placed in a muffle furnace for roasting, the heating rate of the roasting is 5°C / min, the temperature is raised to 550°C and kept for 2h, and the in-situ-Co-g-C is obtained after natural cooling 3 N 4 ;

[0042] (5) to be described in-situ-Co-g-C 3 N 4 After natural cooling, wash by centrifugation with deionized water for 3 to 4 times, and then dry in an oven at 70°C.

Embodiment 2

[0044] An in-situ-Co-g-C 3 N 4 The synthetic method, it comprises the steps:

[0045] (1) 0.02mol melamine and 0.004mol cobalt chloride hexahydrate were dissolved in 15ml absolute ethanol to obtain solution A;

[0046] (2) Place solution A on a heat-collecting constant-temperature magnetic stirrer and stir evenly, and evaporate to dryness in a water bath at 60° C. to obtain solid product A;

[0047] (3) Transfer the solid product A obtained by evaporating to dryness in step (2) into an oven, dry it completely at 50° C., and grind it evenly;

[0048] (4) The uniformly ground solid product A is placed in a muffle furnace for roasting, the heating rate of the roasting is 5°C / min, the temperature is raised to 500°C and kept for 3h, and the in-situ-Co-g-C is obtained after natural cooling 3 N 4 ;

[0049] (5) to be described in-situ-Co-g-C 3 N 4 After natural cooling, centrifuge and wash with deionized water for 3 to 4 times, and then dry in an oven at 50°C.

Embodiment 3

[0051] An in-situ-Co-g-C 3 N 4 The synthetic method, it comprises the steps:

[0052] (1) 0.08mol melamine and 0.004mol cobalt chloride hexahydrate were dissolved in 30ml absolute ethanol to obtain solution A;

[0053] (2) Place the solution A on a heat-collecting constant temperature magnetic stirrer and stir evenly, and evaporate to dryness in a water bath at 90° C. to obtain a solid product A;

[0054] (3) Transfer the solid product A obtained by evaporating to dryness in step (2) into an oven, dry it completely at 80° C., and grind it evenly;

[0055] (4) The uniformly ground solid product A is placed in a muffle furnace for roasting, the heating rate of the roasting is 10°C / min, the temperature is raised to 530°C and kept for 2.5h, and the in-situ-Co-g-C is obtained after natural cooling 3 N 4 ;

[0056] (5) to be described in-situ-Co-g-C 3 N 4 After natural cooling, centrifuge and wash with deionized water for 3 to 4 times, and then dry in an oven at 100°C.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com