Small household garbage pyrolysis and gasification incinerator and pyrolysis and gasification method

A technology of pyrolysis gasification and domestic waste, applied in the direction of combustion method, incinerator, combustion type, etc., can solve the problem of high work intensity and operation difficulty of operators, inability to realize waste pyrolysis reaction, and poor stability of pyrolysis gas physical properties and other problems, to achieve the effect of smooth operation, stable pyrolysis gas composition and temperature, and small fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

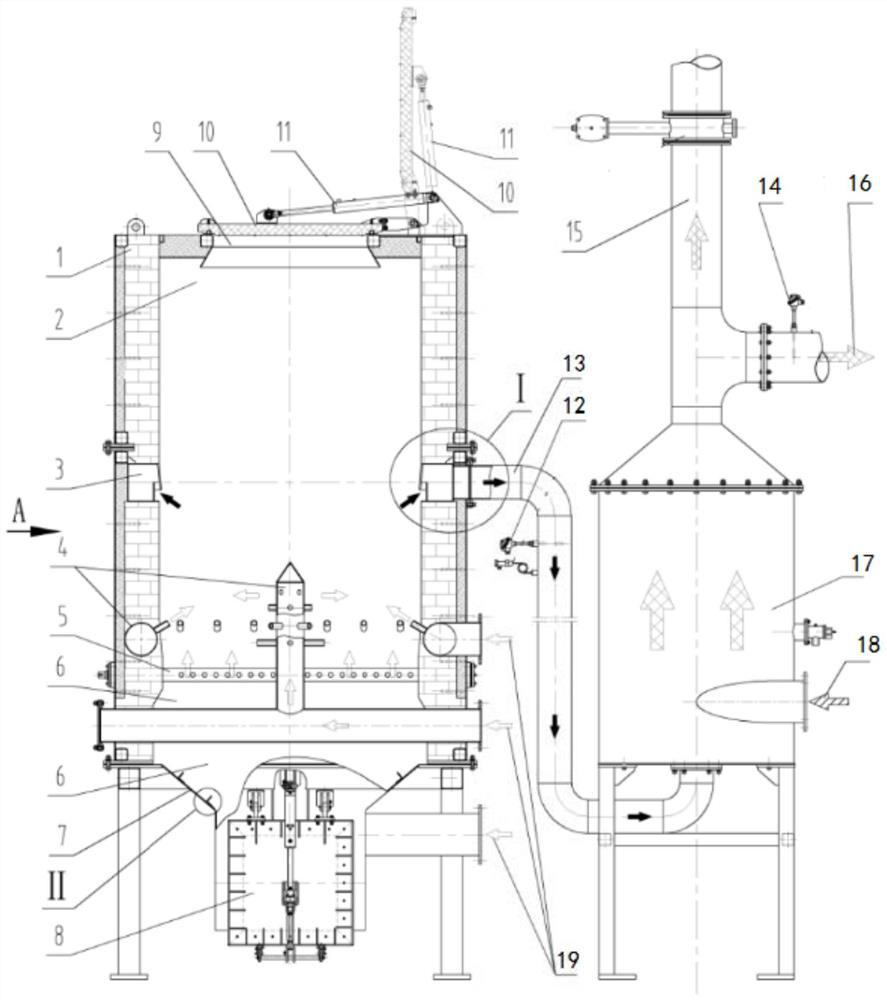

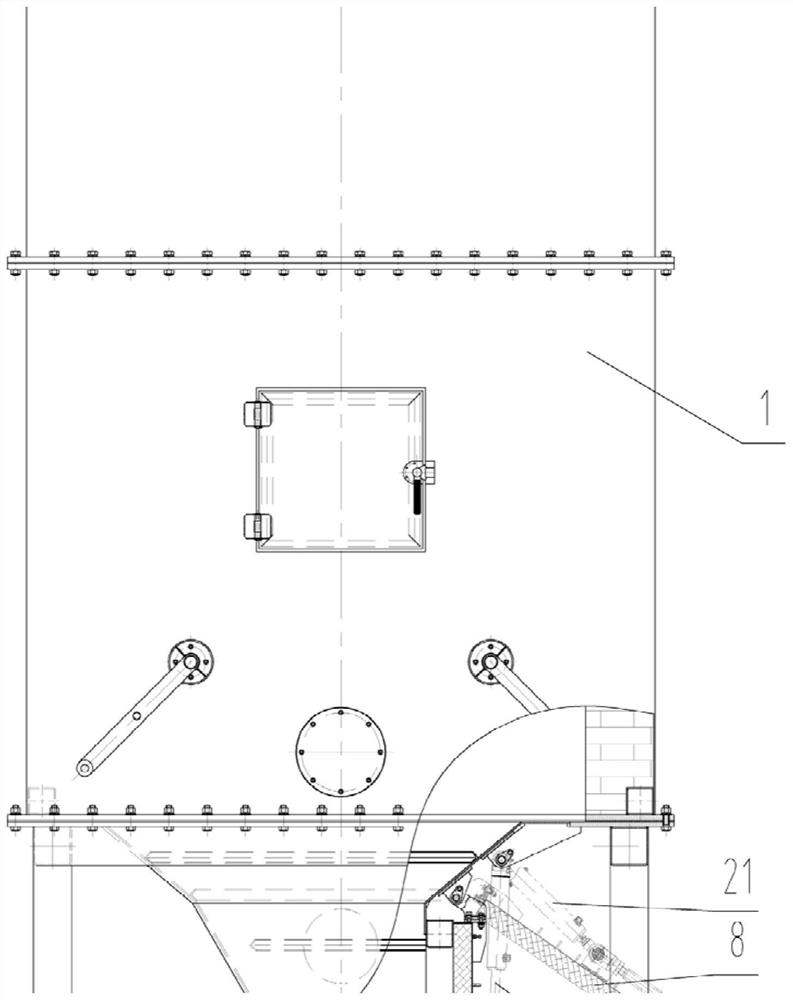

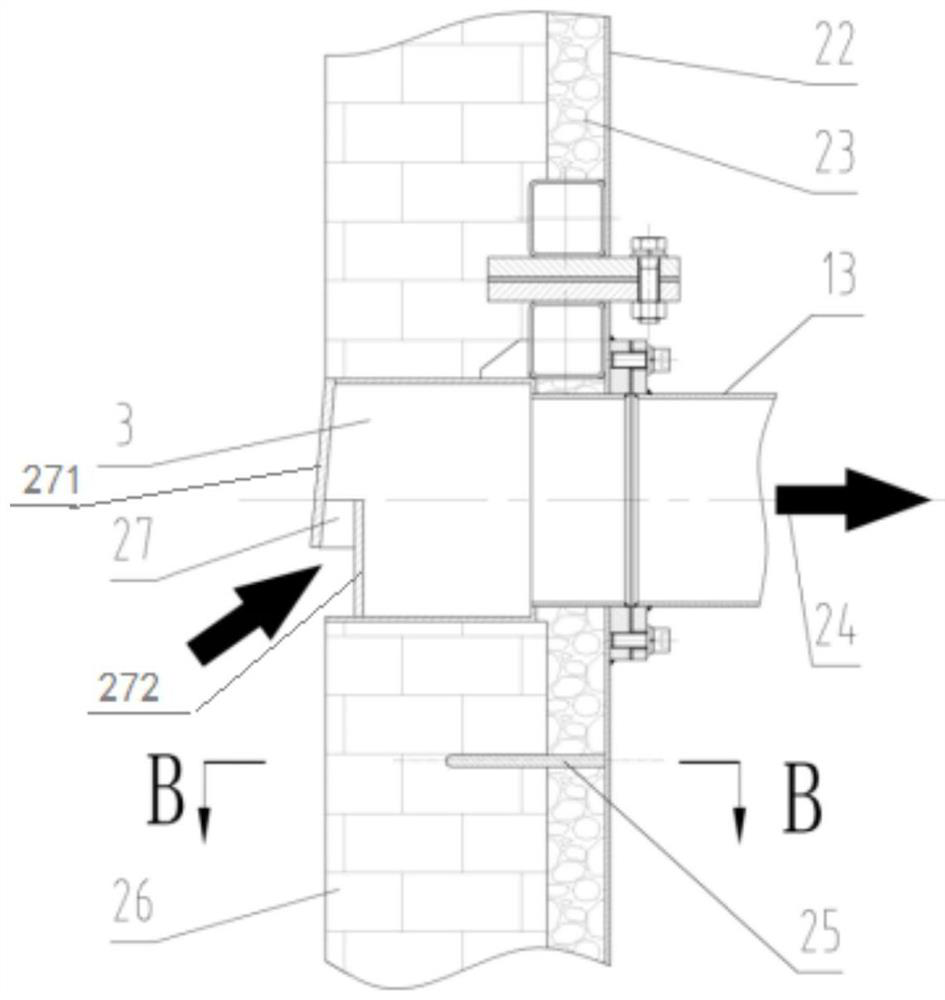

[0087] like Figure 1-2 As shown, the small domestic waste pyrolysis gasification incinerator proposed in the embodiment of the present invention includes: a furnace body 1, a grate 5, a smoke collecting pipe 3, a pyrolysis gas output pipe 13, a secondary combustion chamber 17, a slag collecting pipe bucket 7;

[0088] The inside of the furnace body 1 is a cavity, and the top is provided with a feeding port 9 and a feeding door 10 that can be sealed with the feeding port 9; in order to facilitate the control of the opening and closing state of the feeding door 10, in this embodiment, the A feed gate drive mechanism 11 is provided between the feed gate 10 and the top of the furnace body 1 .

[0089] The grate 5 is located in the furnace body 1 and divides the cavity of the furnace body 1 into an upper furnace chamber 2 and a lower ash cavity 6; that is, the grate 5 and the furnace body 1 The space enclosed by the inner surface of the side wall, the top, and the feeding door 1...

Embodiment 2

[0114] The pyrolysis gasification method of the small domestic waste pyrolysis gasification incinerator of the present embodiment, such as Figure 7 As shown, it is realized by the small-scale domestic waste pyrolysis gasification incinerator described in Example 1, which includes the following steps:

[0115] The garbage moves from top to bottom in the furnace 2, and forms an oxygen-free preheating drying zone 30, an oxygen-free pyrolysis gasification zone 31, and an oxygen-depleted atmosphere from top to bottom in the furnace 2. Deep burning zone 32, burnout zone 33 in oxygen-enriched atmosphere.

[0116] Specifically, the garbage enters the furnace chamber 2, and firstly, enters the preheating and drying zone 30 in an oxygen-free atmosphere (here, "anaerobic" refers to an extremely oxygen-depleted state that is almost oxygen-free), where the garbage is preheated and dried. The zone 30 is preheated and dried, and in the process of preheating and drying, it gradually moves t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com