Curing oven tail gas environmental protection treating system

A technology for environmental protection treatment and curing furnace, which is used in surface pretreatment, chemical instruments and methods, and removal of smoke and dust. Compact, stable performance, and the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

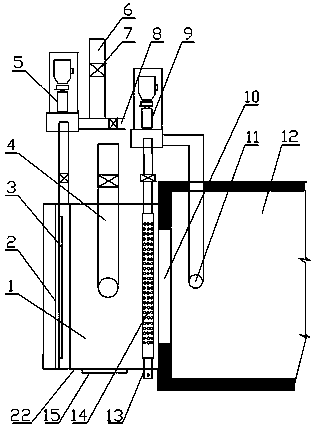

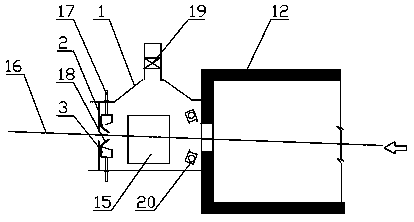

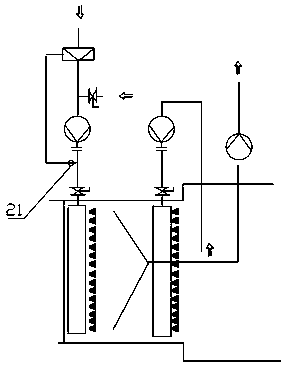

[0016] see Figure 1-3 , the present invention is a curing furnace tail gas environmental protection treatment system, with a flue gas treatment box 22, the upper part of the box is provided with a smoke collection hood 1, the smoke collection hood is provided with a waste gas pipeline 4 and a waste gas valve 19, one end of the box It is connected with the outlet 10 of the curing furnace, and the other end of the box body is connected to the strip steel water quenching tank. The strip steel 16 comes out from the curing furnace outlet and enters the strip steel water quenching tank through the box body. Blowing device, be positioned at the strip steel passing outlet position of casing to be provided with air knife blowing device; Described air curtain blowing device comprises air curtain blower 9, and the air inlet of air curtain blower is connected in the curing furnace 12 through pipeline, and pipeline The inlet of the air curtain fan is the suction port 11 in the air curtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com