A modified polyethylene microorganism carrier filler

A microbial carrier and polyethylene technology, applied in biological water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of poor thermal stability, low packing strength, low impact strength, etc., to achieve It is not easy to loosen and deform, increase the amount of biofilm, and enhance the effect of hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

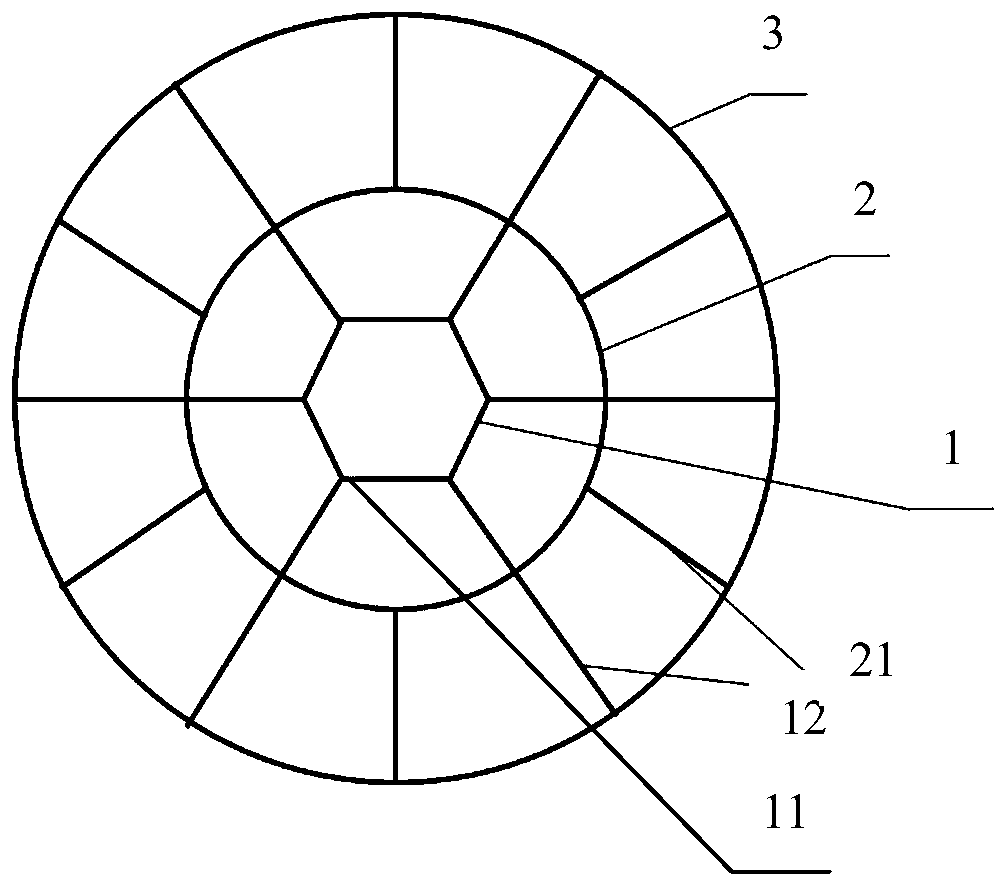

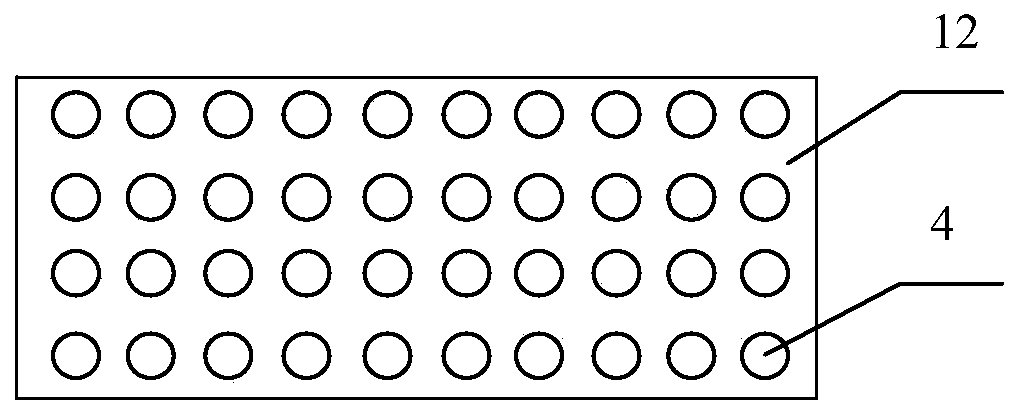

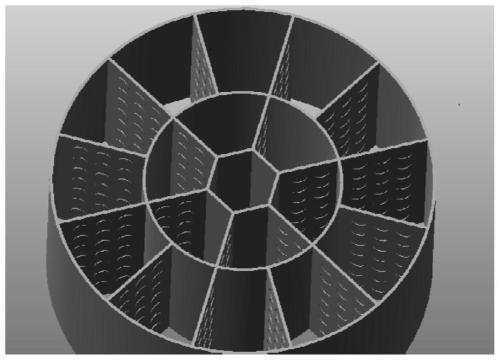

[0021] Such as Figures 1 to 3 As shown, the microbial carrier filler is 12 mm high and 25 mm in diameter. The center of the main frame is a hexagonal ring 1 with a side length of 2 mm. Six longitudinal ribs 11 of the hexagonal ring 1 are fixed with first radial ribs 12. , the first radial rib 12 passes through the first ring 2 outside the hexagonal ring 1 and is fixed to the inner wall of the second ring 3, and the diameter of the first ring 2 is 12 mm; the outer wall of the first ring 2 is connected to the second ring The inner walls of the ring 3 are fixedly connected by the second radial ribs 21, the first radial ribs 12 and the second radial ribs 21 are distributed at intervals, the surfaces of the first radial ribs 12 and the second radial ribs 21 are There are circular grooves 4 arranged longitudinally, the diameter of the grooves 4 is 1mm, the depth is 0.4mm, and the distance between adjacent grooves is 2mm.

[0022] The preparation process of the microbial carrier fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com