Industrial sewage treatment device

A sewage treatment device, industrial technology, applied in water/sewage treatment, water/sewage treatment equipment, water/sewage multi-stage treatment, etc. The effect of high reaction rate, high sewage treatment efficiency and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

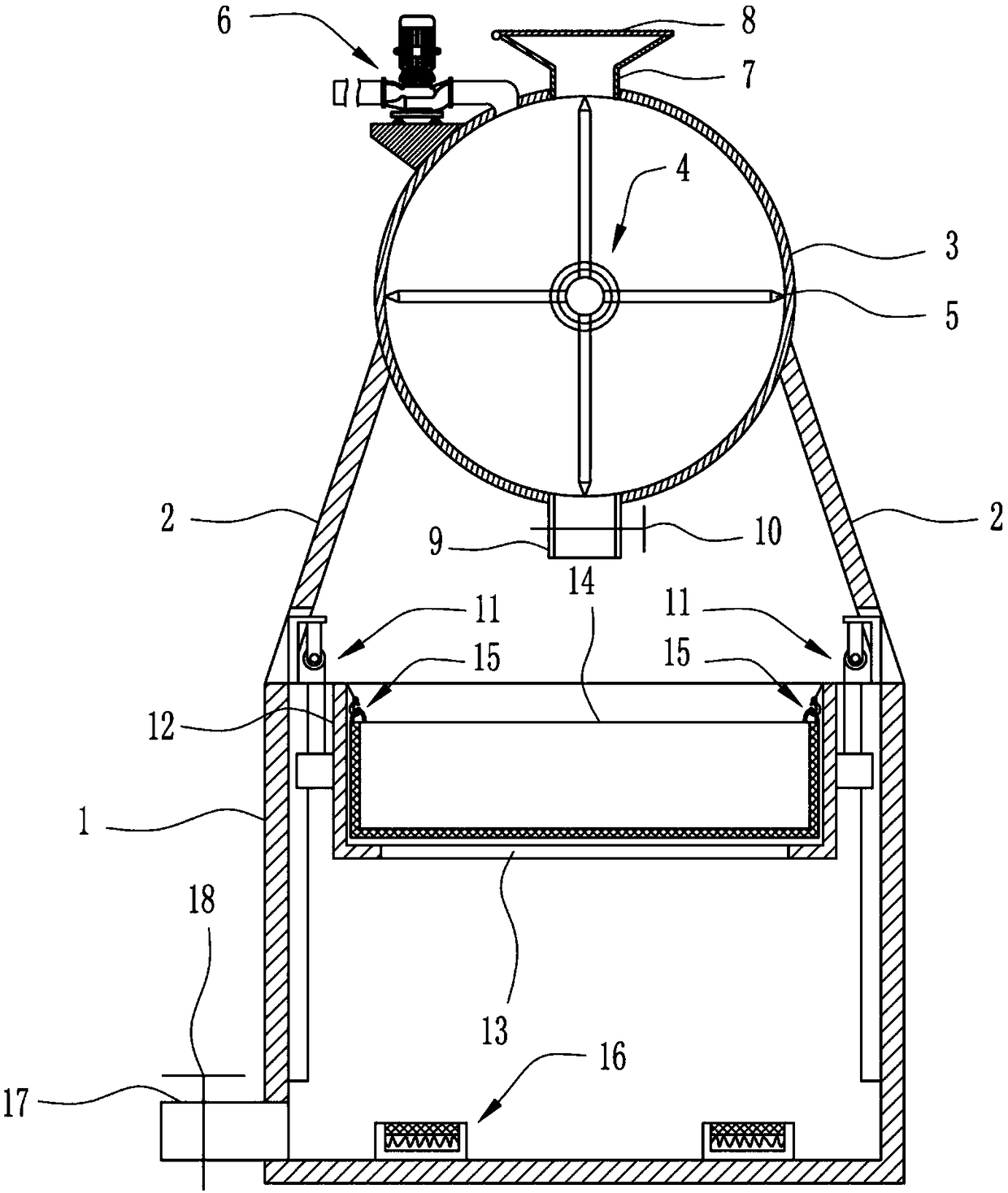

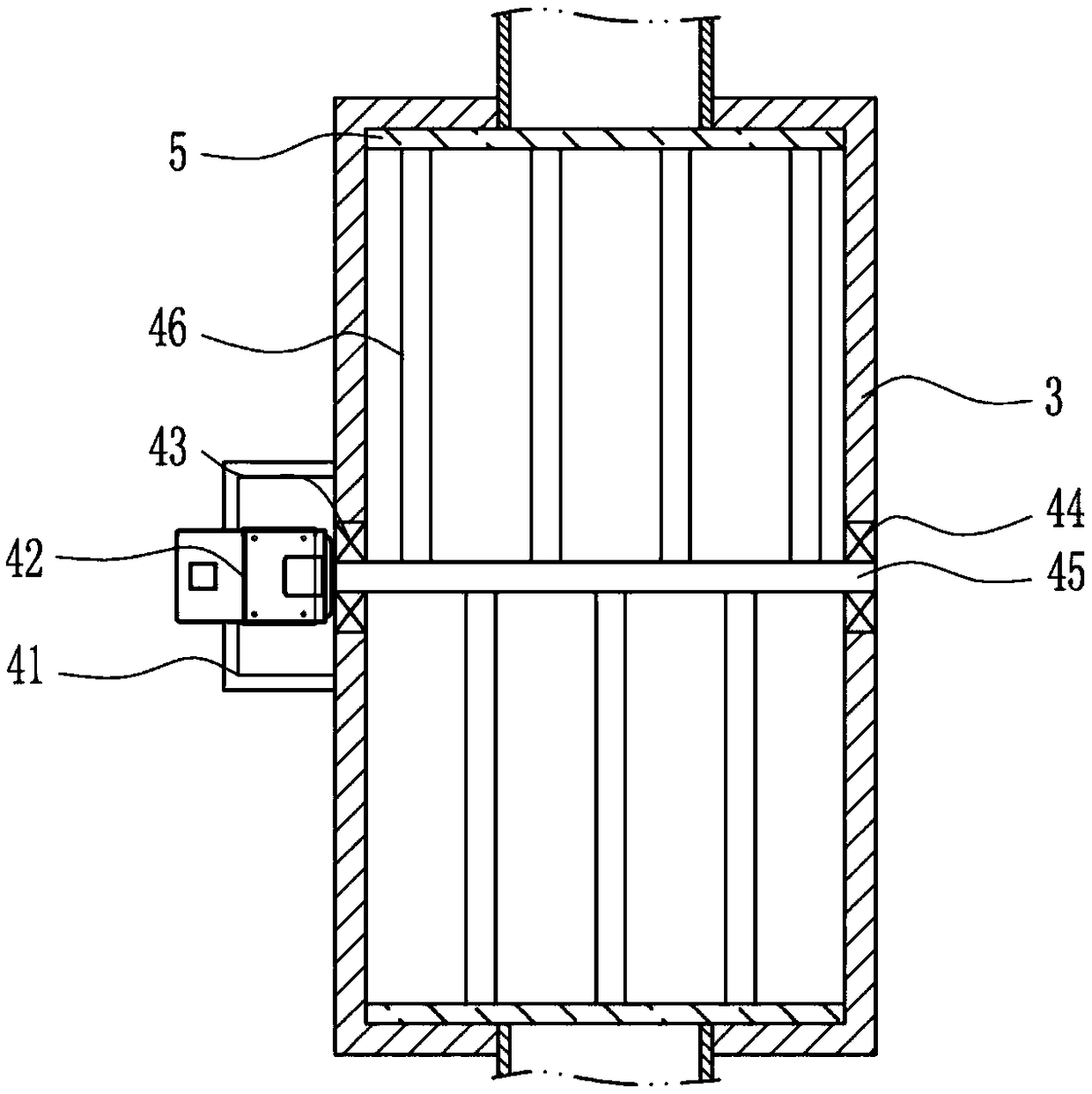

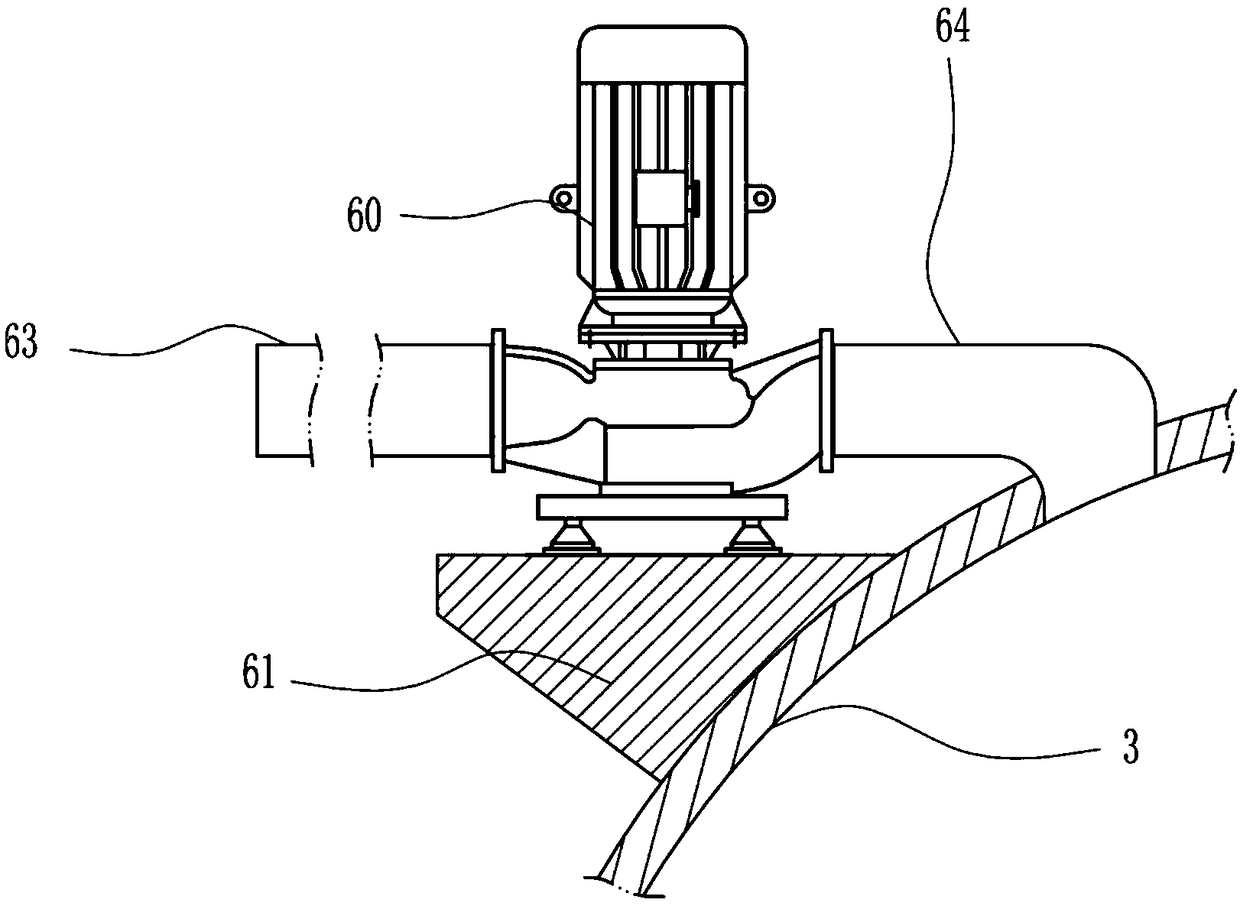

[0027] An industrial sewage treatment device, such as Figure 1-8 As shown, it includes a first installation frame 1, a support plate 2, a column mixing box 3, a stirring mechanism 4, a scraper 5, a pumping mechanism 6, a dosing bucket 7, a cover plate 8, a first discharge pipe 9, and a first valve 10. Auxiliary mechanism 11, second installation frame 12, filter frame 14, assembly mechanism 15 and heating mechanism 16; the column mixing box 3 is fixed on the top of the first installation frame 1 through two support plates 2, and the support plate 2 is connected with the first The central axis of the length direction of the installation frame 1 is arranged symmetrically; the stirring mechanism 4 is installed on the side of the column mixing box 3, and the output end of the stirring mechanism 4 is located in the column mixing box 3; the scraper 5 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com