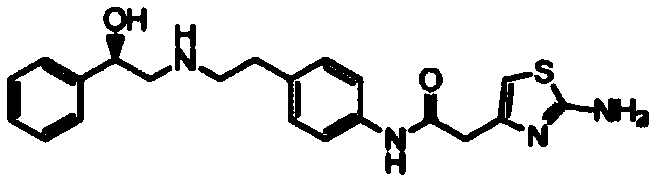

Method for synthesizing Mirabegron intermediate by microchannel reactor

A microchannel reactor, Mirabegron technology, applied in chemical instruments and methods, chemical/physical/physical-chemical reactors, preparation of organic compounds, etc. problems such as low yield, to achieve the effects of stable online production and post-processing, reduction of production costs, and improvement of yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

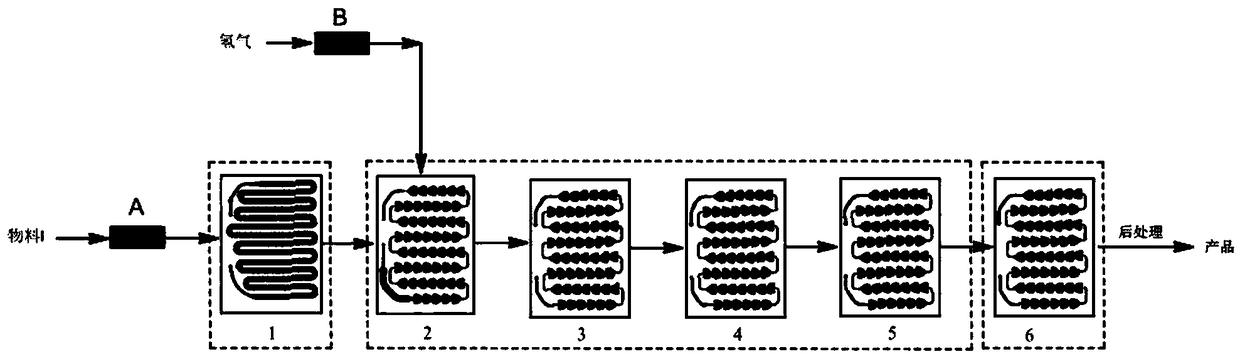

[0043] Embodiment 1: the method for the synthesis of mirabegron intermediate in microchannel reactor.

[0044] This embodiment provides a kind of method that microchannel reactor synthesizes Mirabegron intermediate, and concrete steps are as follows:

[0045] 1) Weigh 180g of the raw material (ALPHAR)-ALPHA-[[[2-(4-nitrophenyl)ethyl]amino]methyl]benzyl alcohol into 3L of methanol, stir well and add 10g of Pd The Pd / C catalyst with a content of 10% is fully stirred and mixed to form a material I, and the material I is transported to the preheating module 1 of the microchannel reactor for preheating, and then enters the reaction module group of the microchannel reactor after preheating.

[0046] 2) Hydrogen is delivered to the reaction module group of the microchannel reactor and step 1) reacts with the preheated material I in the reaction module group, wherein: adjust the flow rate of the slurry pump so that the flow rate of the material I is 40.0g / min , adjust H 2 The flow r...

Embodiment 2

[0047] Embodiment 2: the method for the synthesis of mirabegron intermediate in microchannel reactor.

[0048] This embodiment provides a kind of method that microchannel reactor synthesizes Mirabegron intermediate, and concrete steps are as follows:

[0049] 1) Weigh 180g of the raw material (ALPHAR)-ALPHA-[[[2-(4-nitrophenyl)ethyl]amino]methyl]benzyl alcohol into 3L of ethanol, stir well and add 12g of Pd mass The Pd / C catalyst with a content of 5% is fully stirred and mixed to form a material I, and the material I is transported to the preheating module 1 of the microchannel reactor for preheating, and then enters the reaction module group of the microchannel reactor after preheating.

[0050] 2) Hydrogen is delivered to the reaction module group of the microchannel reactor and step 1) reacts with the preheated material I in the reaction module group, wherein: adjust the flow rate of the slurry pump to make the flow rate of the material I 30.0g / min , adjust H 2 The flow r...

Embodiment 3

[0051] Embodiment 3: the method for the synthesis of mirabegron intermediate in microchannel reactor.

[0052] This embodiment provides a kind of method that microchannel reactor synthesizes Mirabegron intermediate, and concrete steps are as follows:

[0053] 1) Weigh 240g of the raw material (ALPHAR)-ALPHA-[[[2-(4-nitrophenyl)ethyl]amino]methyl]benzyl alcohol into 4.5L of ethanol, stir well and add 16g of Pt The Pt / C catalyst with a mass content of 5% is fully stirred and mixed to form a material I, and the material I is transported to the preheating module 1 of the microchannel reactor for preheating, and then enters the reaction module group of the microchannel reactor after preheating.

[0054] 2) Hydrogen is delivered to the reaction module group of the microchannel reactor and step 1) the material I after preheating is reacted in the reaction module group, wherein: adjust the flow rate of the slurry pump so that the flow rate of the material I is 25.0g / min , adjust H 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com