Method for modifying corn starch with different amylose contents by air atmospheric pressure plasma jet

A technology of atmospheric pressure plasma and amylose content, applied in food science and other fields, can solve the problems of uneven processing and low yield of dry processing, and achieve improved application performance, increased water binding capacity, and increased water expansion volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The method for modifying cornstarch with different amylose content by the air atmospheric pressure plasma jet of the present embodiment comprises the following steps:

[0025] (1) Take waxy corn starch with a mass concentration of 5% as raw material, linear chain content of 0%, vortex mixing for 10 min, and then quickly spray it with air atmospheric pressure plasma jet for 1, 3, 5 and 7 min, Power 750 W, height 14.13 mm;

[0026] (2) After treatment, centrifuge at 3000 rpm for 10 min to obtain the precipitate;

[0027] (3) Take the precipitate, centrifuge with absolute ethanol to remove water, 3000 rpm, 10 min, and wash 3 times;

[0028] (4) The obtained precipitate was vacuum freeze-dried at -50°C for 1.5 h, ground, and passed through a 100-mesh standard sieve to obtain modified waxy corn starch.

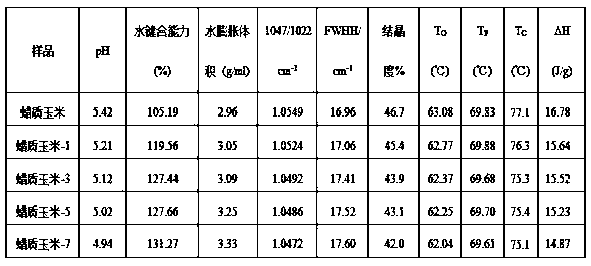

[0029] It is measured that after the waxy cornstarch is treated by the atmospheric air plasma jet, the structural properties of the sample are reduced, the water binding a...

Embodiment 2

[0033] The method for modifying cornstarch with different amylose content by the air atmospheric pressure plasma jet of the present embodiment comprises the following steps:

[0034] (1) Take ordinary cornstarch with a mass concentration of 5% as raw material, with a linear chain content of 23-25%, vortex mixing for 10 minutes, and then quickly spray it with air atmospheric pressure plasma jet for 1, 3, 5 and 7 minutes, Power 750 W, height 14.13 mm;

[0035] (2) After treatment, centrifuge at 3000 rpm for 10 min to obtain the precipitate;

[0036] (3) Take the precipitate, centrifuge with absolute ethanol to remove water, 3000 rpm, 10 min, and wash 3 times;

[0037] (4) The precipitate was obtained, vacuum freeze-dried at -50°C for 1.5 h, ground, and passed through a 100-mesh standard sieve to obtain modified ordinary corn starch.

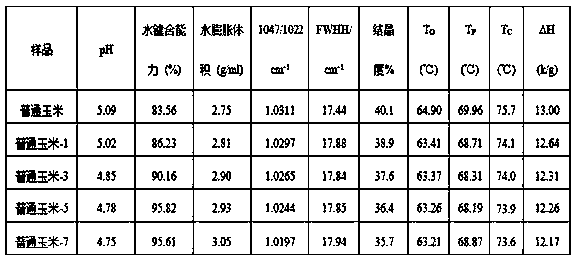

[0038] (5) It is measured that after normal-pressure air plasma jet treatment of ordinary corn starch, the structural properties of the sample d...

Embodiment 3

[0042] The method for modifying cornstarch with different amylose content by the air atmospheric pressure plasma jet of the present embodiment comprises the following steps:

[0043] (1) Take high-amylose corn starch with a mass concentration of 5% as raw material, with an amylose content of 63-67%, vortex mixing for 10 minutes, and then quickly spray it with air atmospheric pressure plasma jet for 1, 3, 5 and 7 minutes, Power 750 W, height 14.13 mm;

[0044] (2) After treatment, centrifuge at 3000 rpm for 10 min to obtain the precipitate;

[0045] (3) Take the precipitate, centrifuge with absolute ethanol to remove water, 3000 rpm, 10 min, and wash 3 times;

[0046] (4) The obtained precipitate was vacuum freeze-dried at -50°C for 1.5 h, ground, and passed through a 100-mesh standard sieve to obtain modified high-amylose corn starch.

[0047] It is measured that after the treatment of high-amylose corn starch by atmospheric air plasma jet, the structural properties of the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com