A kind of magnetic abrasive and preparation method thereof

A technology of magnetic abrasives and magnetic materials, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of long time required for the preparation of magnetic abrasives, uniform mixing of different metal powders, and further improvement in performance, and achieve simple technical solutions Controllable, good surface quality, and improved grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

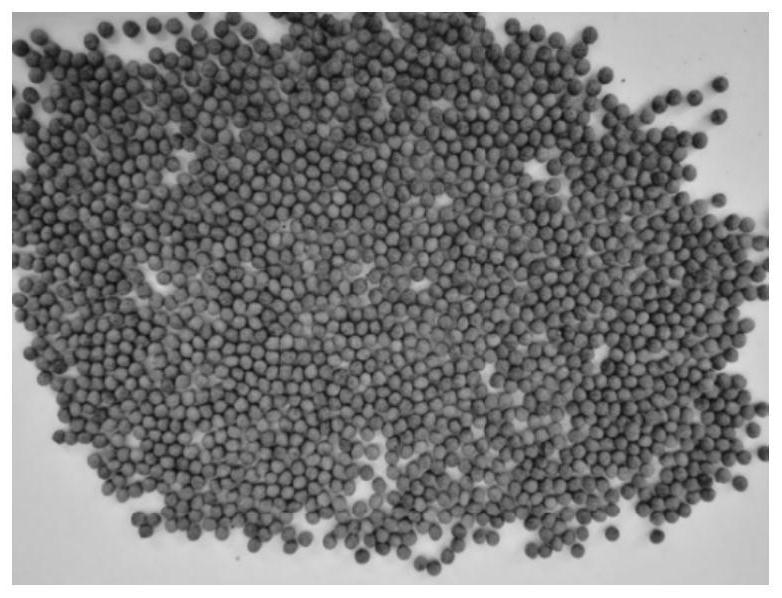

[0059] The magnetic abrasive in this embodiment includes a core and a shell covering the surface of the core. The shell is a metal salt, and the core is a magnetic abrasive body. A bond is formed between the metal salt and the abrasive former in the magnetic abrasive body. The magnetic abrasive body includes the following components in parts by weight: 3.4 parts of abrasive forming agent, 16 parts of Fe powder, Al 2 o 3 Powder 1.6 parts. Metal salt is FeCl 3 2.7 servings. The abrasive forming agent is composed of alginate, carboxymethyl cellulose and polyacrylic acid resin in a mass ratio of 1.4:0.2:1.8. The particle size of iron powder is W3, Al 2 o 3 The particle size of the powder is W1. The morphology of the magnetic abrasive material of the present embodiment is as figure 1 shown.

[0060] The preparation method of the magnetic abrasive material of the present embodiment may further comprise the steps:

[0061] 1) Take the raw materials for subsequent use acco...

Embodiment 2

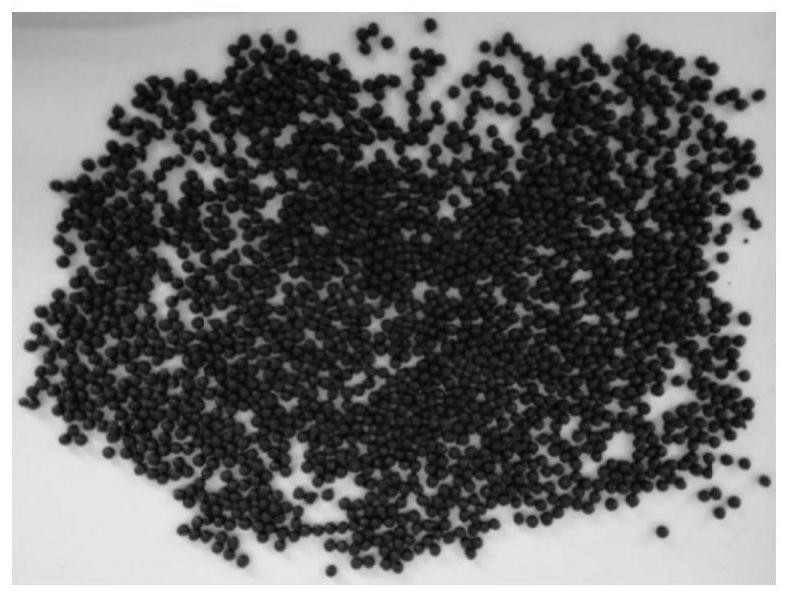

[0066] The magnetic abrasive in this embodiment includes a core and a shell covering the surface of the core. The shell is a metal salt, and the core is a magnetic abrasive body. A bond is formed between the metal salt and the abrasive former in the magnetic abrasive body. The magnetic abrasive body includes the following components in parts by weight: 3.4 parts of abrasive forming agent, 16 parts of Fe powder, Al 2 o 3 Powder 1.6 parts. Metal salt is MgCl 2 2.7 servings. The abrasive forming agent is composed of alginate, carboxymethyl cellulose, and polyamide resin in a mass ratio of 1.4:0.2:1.8; the particle size of the iron powder is W3, Al 2 o 3 The particle size of the powder is W1. The morphology of the magnetic abrasive material of the present embodiment is as figure 2 shown.

[0067] The preparation method of the magnetic abrasive material of the present embodiment may further comprise the steps:

[0068] 1) Take the raw materials for subsequent use accord...

Embodiment 3

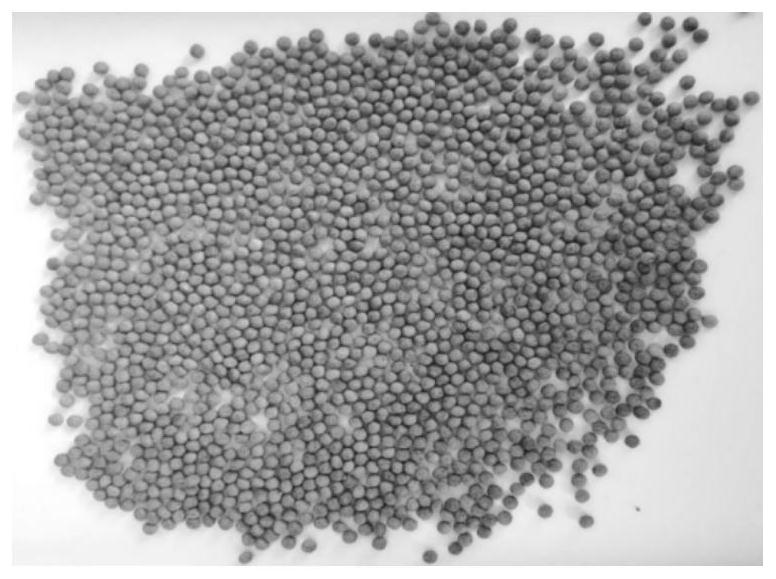

[0073] The magnetic abrasive in this embodiment includes a core and a shell covering the surface of the core. The shell is a metal salt, and the core is a magnetic abrasive body. A bond is formed between the metal salt and the abrasive former in the magnetic abrasive body. The magnetic abrasive body includes the following components in parts by weight: 3.4 parts of abrasive forming agent, 16 parts of Fe powder, Al 2 o 3 Powder 1.6 parts. Metal salt is BaCl 2 2.7 servings. The abrasive forming agent is composed of alginate, carboxymethyl cellulose, and epoxy resin in a mass ratio of 1.4:0.2:1.8; the particle size of the iron powder is W3, Al 2 o 3 The particle size of the powder is W1. The morphology of the magnetic abrasive material of the present embodiment is as image 3 shown.

[0074] The preparation method of the magnetic abrasive material of the present embodiment may further comprise the steps:

[0075] 1) Take the raw materials according to the following par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com