Mycoplasma gallisepticum high density fermentation culture technology

A high-density fermentation technology of Mycoplasma gallisepticum, which is applied in the field of agricultural microorganisms, can solve problems such as the difficulty of large-scale production of Mycoplasma gallisepticum, and achieve the effects of improving the protection effect, improving immunogenicity, and increasing the density of viable bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

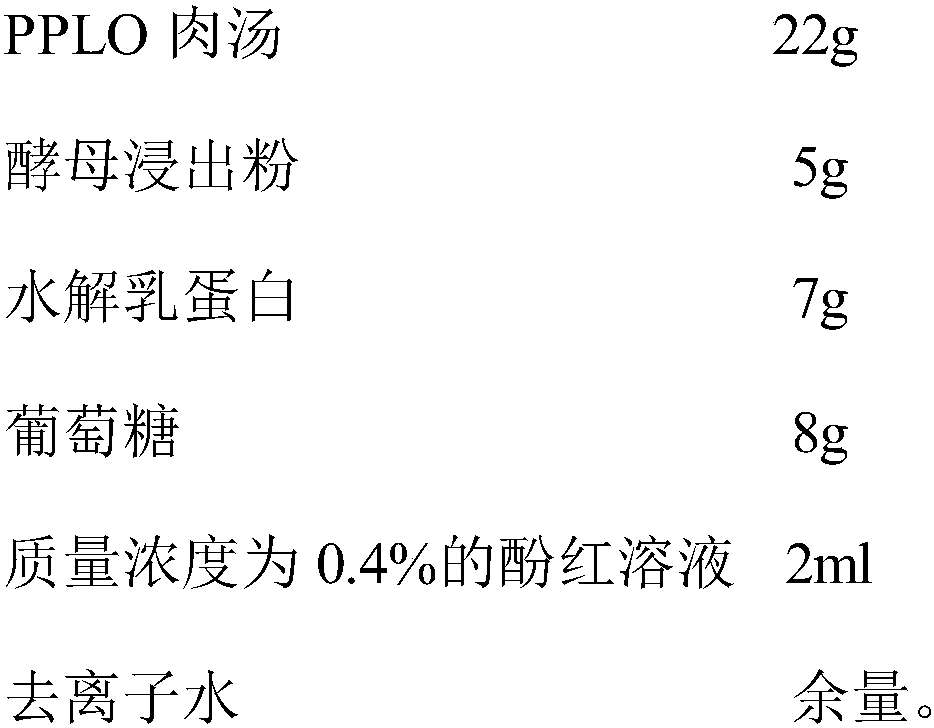

[0022] A kind of Mycoplasma gallisepticum high-density fermentation culture technique provided by the present embodiment 1 comprises the following steps:

[0023] Step 1: Take the freeze-dried seeds of Mycoplasma gallisepticum for production and inoculate them in the culture medium of Mycoplasma gallisepticum at a ratio of 1:10, and culture them for 18-24 hours under the condition of 36-37°C to obtain the culture medium, and in the same way The obtained culture medium was inoculated and passaged again at a ratio of 1:10;

[0024] Step 2: Inoculate the bacterium liquid after the above-mentioned subculture into the sterilized Mycoplasma gallisepticum culture medium of a 20L fermenter at a ratio of 3% / V / V, and the cultivation process conditions of the fermenter are: the temperature is 37°C, and the tank pressure is 0.03Mpa, the dissolved oxygen is 40%, the pH value is 7.7, and the stirring speed is 100rpm. During the cultivation process, when adding 20% NaOH solution online to ...

Embodiment 2

[0030] A kind of Mycoplasma gallisepticum high-density fermentation culture process that present embodiment 2 provides, comprises the following steps:

[0031] Step 1: Take the freeze-dried seeds of Mycoplasma gallisepticum for production and inoculate them in the culture medium of Mycoplasma gallisepticum at a ratio of 1:10, and culture them for 18-24 hours under the condition of 36-37°C to obtain the culture medium, and in the same way The obtained culture medium was inoculated and passaged again at a ratio of 1:10;

[0032] Step 2: Inoculate the bacterium liquid after the above-mentioned subculture into the sterilized Mycoplasma gallisepticum culture medium of a 20L fermenter at a ratio of 4% / V / V, and the cultivation process conditions of the fermenter are: the temperature is 37°C, and the tank pressure is 0.05Mpa, the dissolved oxygen is 40%, the pH value is 7.7, and the stirring speed is 100rpm. During the cultivation process, when adding 20% NaOH solution online to con...

Embodiment 3

[0039] A kind of Mycoplasma gallisepticum high-density fermentation culture technique provided by the present embodiment 3 comprises the following steps:

[0040] Step 1: Take the freeze-dried seeds of Mycoplasma gallisepticum for production and inoculate them in the culture medium of Mycoplasma gallisepticum at a ratio of 1:10, and culture them for 18-24 hours under the condition of 36-37°C to obtain the culture medium, and in the same way The obtained culture medium was inoculated and passaged again at a ratio of 1:10;

[0041]Step 2: Inoculate the bacterium liquid after the above-mentioned subculture into the sterilized Mycoplasma gallisepticum culture medium of a 20L fermenter at a ratio of 3% / V / V, and the cultivation process conditions of the fermenter are: the temperature is 37°C, and the tank pressure is 0.03Mpa, the dissolved oxygen is 40%, the pH value is 7.7, and the stirring speed is 100rpm. During the cultivation process, when adding 20% NaOH solution online to c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com