Composite planting carrier, preparation method and application thereof and submerged grass blanket

A composite planting and carrier technology, applied in the field of submerged planting, can solve the problems of difficult to subvert the traditional submerged plant planting mode, difficult to large-scale production and application, and single utility, so as to overcome the limitations of river conditions, shorten the acceptance period, and shorten the The effect of the construction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

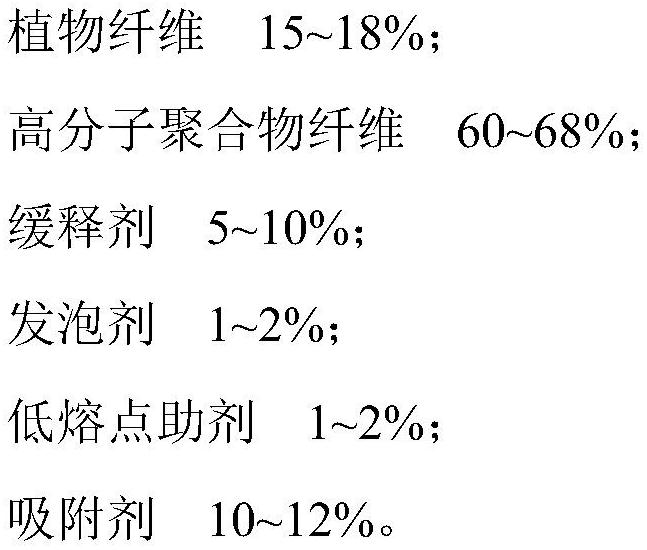

[0042] A composite implant carrier comprises the following components in mass percentage:

[0043] Vegetable fiber: 16%;

[0044] High molecular polymer fiber: 67%;

[0045] Sustained release agent 5%;

[0046] Foaming agent 1%;

[0047] Low melting point additive 1%;

[0048] Sorbent 10%.

[0049] Wherein, the plant fiber is lignocellulose; the high molecular polymer fiber is polyester fiber; the slow release agent is citric acid; the foaming agent is a low-melting point polyurethane foaming agent: ADC polyurethane foaming agent; the low melting point auxiliary agent is a low melting point polyester fiber: ADC polyester fiber (polyester) mixture with a melting point of 40° C.; the adsorbent is a carbon adsorbent.

[0050] The specification of the composite implant carrier is 10 holes.

[0051] The preparation method of the composite planting carrier comprises the following steps: combing, laying, knitting, hot air setting, cold air setting, dipping in an aqueous solutio...

Embodiment 2

[0062] A composite implant carrier comprises the following components in mass percentage:

[0063] Vegetable fiber 18%;

[0064] High molecular polymer fiber 60%;

[0065] Sustained release agent 8%;

[0066] Foaming agent 2%;

[0067] Low melting point additive 1%;

[0068] Sorbent 11%.

[0069] Wherein, the plant fiber is palm cellulose; the macromolecular polymer fiber is polyurethane fiber; the slow-release agent is citric acid; the foaming agent is a low-melting point polyurethane foaming agent: the melting point is ADC polyurethane foaming agent at 100°C; the low-melting-point auxiliary agent is a low-melting point polyester fiber: ADC polyester fiber (polyester) mixture with a melting point of 65°C; the adsorbent is a carbon adsorbent.

[0070] The specification of the composite implant carrier is 10 holes.

[0071] The preparation method of a composite planting carrier comprises the following steps: combing, laying, knitting, hot air setting, cold air setting, di...

Embodiment 3

[0082] A composite implant carrier comprises the following components in mass percentage:

[0083] Vegetable fiber 15%;

[0084] High molecular polymer fiber 68%;

[0085] Sustained release agent 5%;

[0086] Foaming agent 1%;

[0087] Low melting point additive 1%;

[0088] Sorbent 10%.

[0089] Wherein, the plant fiber is lignocellulose; the macromolecular polymer fiber is polyurethane fiber; the slow-release agent is citric acid; the foaming agent is a low-melting point polyurethane foaming agent: the melting point is ADC polyurethane foaming agent at 45°C; the low melting point auxiliary agent is a low melting point polyester fiber: ADC polyester fiber (polyester) mixture with a melting point of 50°C; the adsorbent is a carbon adsorbent.

[0090] The specification of the composite implant carrier is 10 holes.

[0091] The preparation method of a composite planting carrier comprises the following steps: combing, laying, knitting, hot air setting, cold air setting, dip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com